Display device

A technology for display devices and display parts, which is applied to identification devices, static indicators, instruments, etc., can solve the problems of inability to represent display transistors, inability to represent multiple transistors, and inability to monitor the process of loading and unloading protective films, and achieves the effect of strengthening static electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

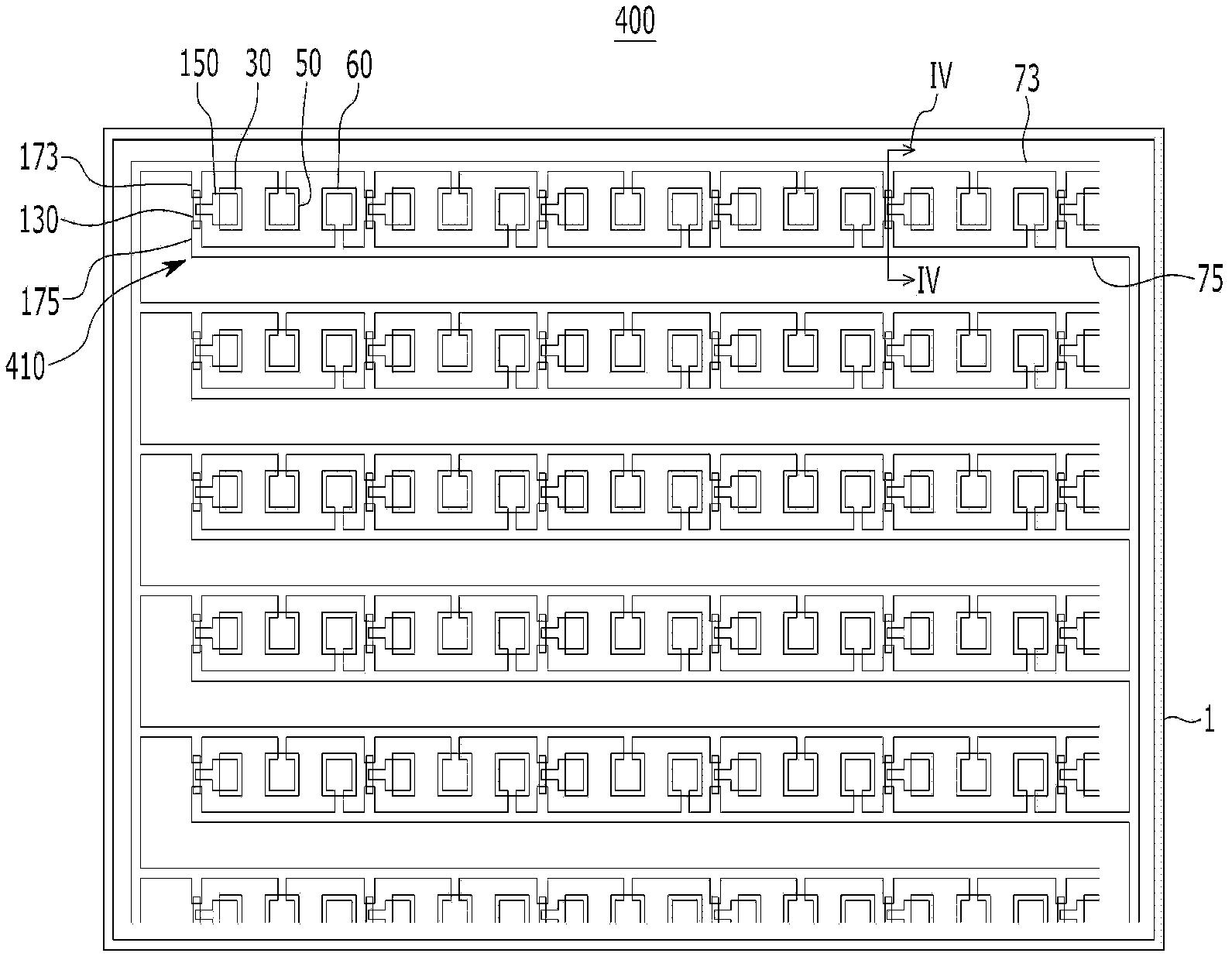

[0042] Hereinafter, embodiments of the present invention will be described with reference to the drawings so that those skilled in the art to which the present invention pertains can easily implement the present invention. The present invention can be implemented in various forms and is not limited to the embodiments described here.

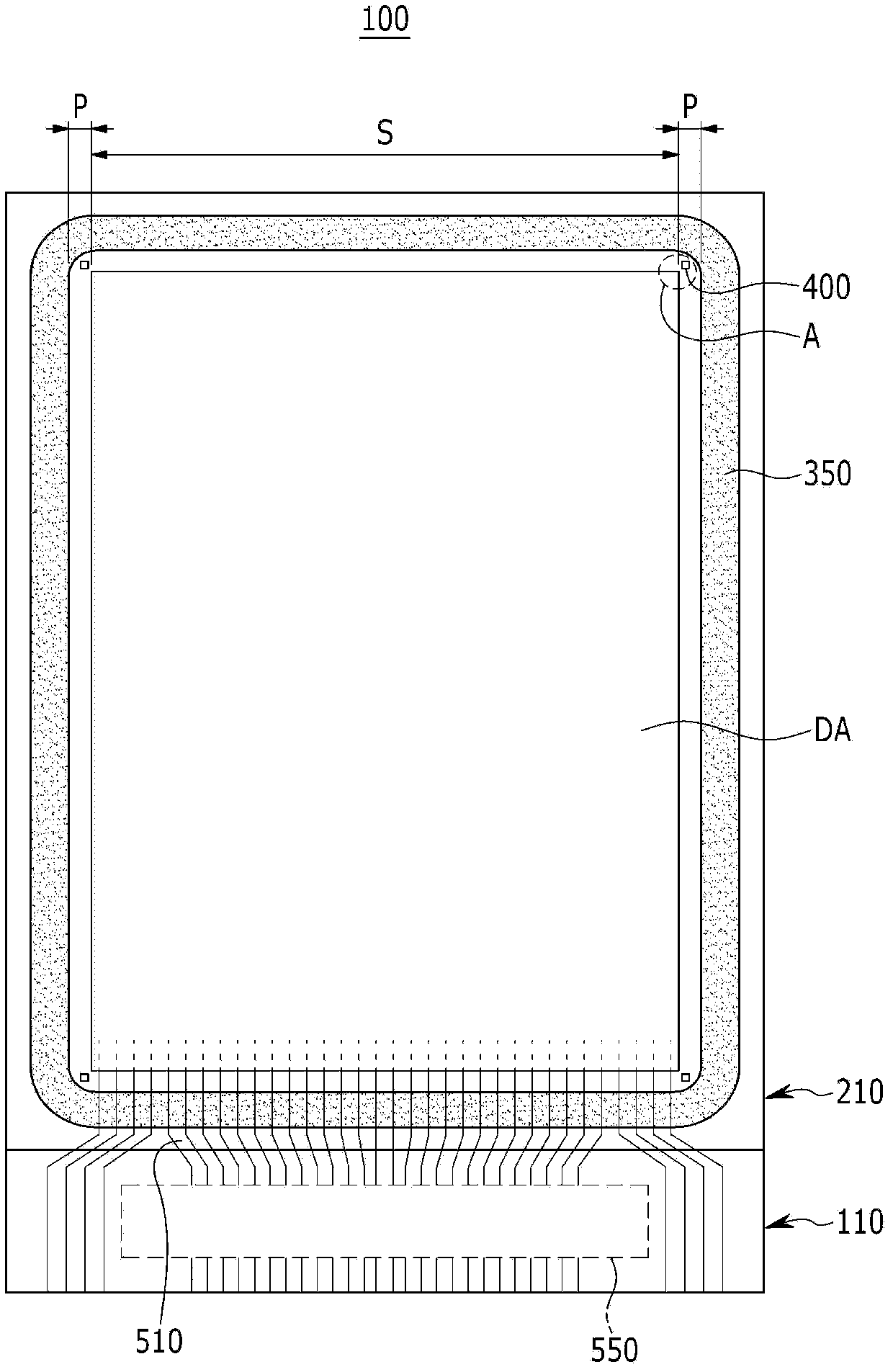

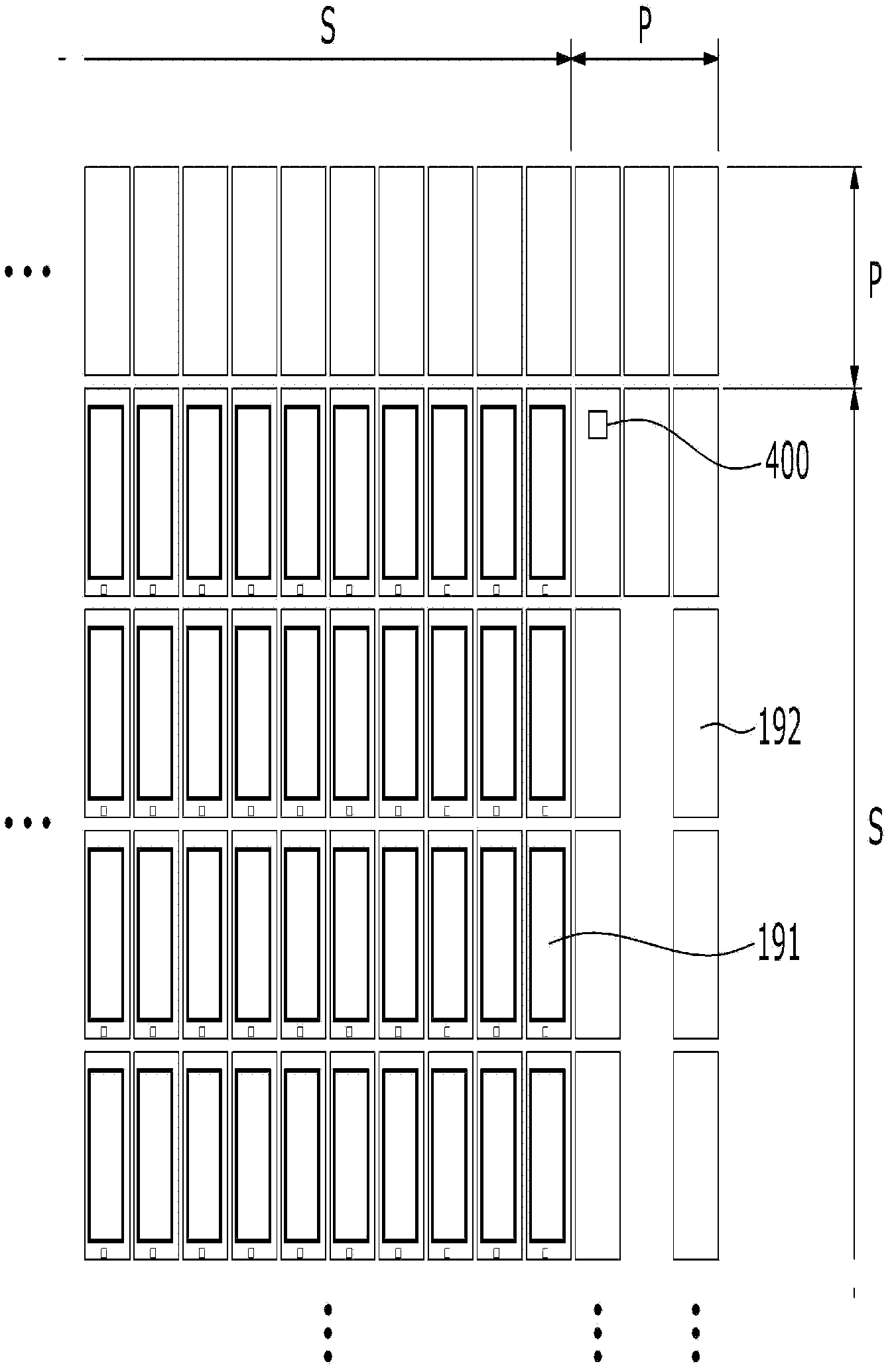

[0043] figure 1 is a plan view of a display device according to a first embodiment of the present invention, figure 2 yes figure 1 A magnified view of part A of .

[0044] Such as figure 1 As shown, the display device 100 according to the first embodiment of the present invention includes: a display substrate 110 ; a sealing member 210 covering the display substrate 110 ; and a sealant 350 disposed between the display substrate 110 and the sealing member 210 .

[0045] The sealant 350 is disposed along the edge of the sealing member 210 , and the sealant 350 makes the display substrate 110 and the sealing member 210 adhere and seal together....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com