Security management and control command system

A command system, safety control technology, applied in the direction of comprehensive factory control, electrical program control, etc., can solve the problems of on-site safety control limitations, on-site inspection of construction personnel's own quality, failure to form on-site safety supervision and management, etc., to achieve personnel qualification management and review, reducing the probability of safety incidents, and the effect of effective management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

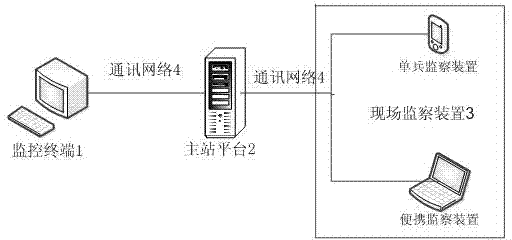

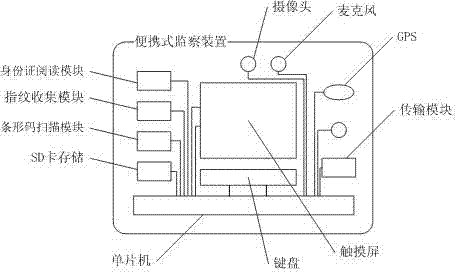

[0025] In this embodiment, the communication network 4 adopts WIFI or 3G network. In this example, if figure 2 , the on-site monitoring device 3 is a portable monitoring device, and the portable monitoring device includes an ID card reading module, a fingerprint collection module, a barcode scanning module, a camera, a microphone, a transmission module, a memory, a touch screen, a keyboard and a single-chip microcomputer; the ID card reading module, fingerprint The collection module, barcode scanning module, camera, microphone, transmission module, memory, touch screen and keyboard are all connected to the single-chip microcomputer, and the portable monitoring device is connected to the main station platform 2 through the transmission module. Wherein the memory is an SD card for storing information; and the on-site monitoring device 3 has a built-in power supply, which is a rechargeable battery.

[0026] When the portable monitoring device is working, the user logs in with a...

Embodiment 2

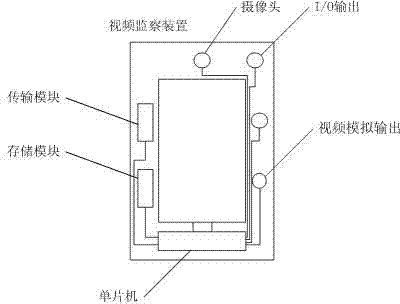

[0029] In this embodiment, the communication network 4 adopts a wired network. In this embodiment, as image 3 The on-site monitoring device 3 is a video monitoring device, and the video monitoring device includes a camera, a video analog output, a transmission module, a storage module and a single-chip microcomputer; Connect with the main station platform 2 through the transmission module.

[0030] The video monitoring device is composed of a camera and a video analog output camera system to collect video, and through the transmission module, the real-time video is returned to the main station platform 2, and the video is archived. At the photographing and evidence collection node, the video surveillance device takes photographs of the scene and uploads them to the main station platform 2 for archiving through the transmission module.

[0031] The video monitoring device supports offline operation. In the offline state, the video monitoring device saves all video information...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com