Laser scanner

A laser scanner and laser beam technology, applied in the field of laser scanners, can solve the problem of small scanning range and achieve the effects of fast scanning speed, wide scanning range and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

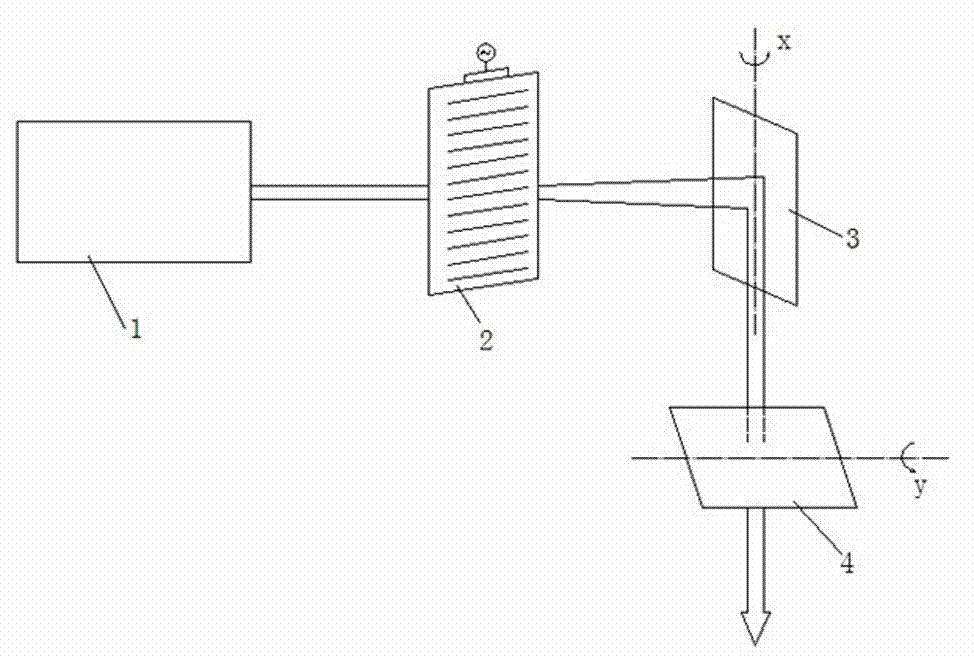

[0008] see figure 1 , a scanner of the present invention is characterized in that it includes: an acousto-optic deflector 2, which is used to diffract the laser beam emitted by the laser 1, and can quickly and accurately control the diffracted beam by controlling the input electrical signal; the vibrating mirror system (x-direction scanning galvanometer 3 and y-direction scanning galvanometer 4), which reflect the diffracted beam from the acousto-optic deflector 2 and realize large-format scanning through its large-angle twist.

[0009] The acousto-optic deflector 2 includes a piezoelectric transducer and an acousto-optic medium for transmitting ultrasonic waves (belongs to conventional technology?).

[0010] The vibrating mirror system includes: reflective mirrors, high-speed swing motors and their control circuits. The control circuit controls two sets of motors to drive the reflective mirrors of vibrating mirrors 3 and 4 to swing at high speed (a conventional technology). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com