Method for testing ESP (electronic stability program) /ABS (anti-lock brake system) pumps

A test method, ABS pump technology, applied in the automotive field, can solve the problems of increased test difficulty, time-consuming test process, easily damaged test bench, etc., to reduce the risk of failure, simplify the test process, and shorten the test cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

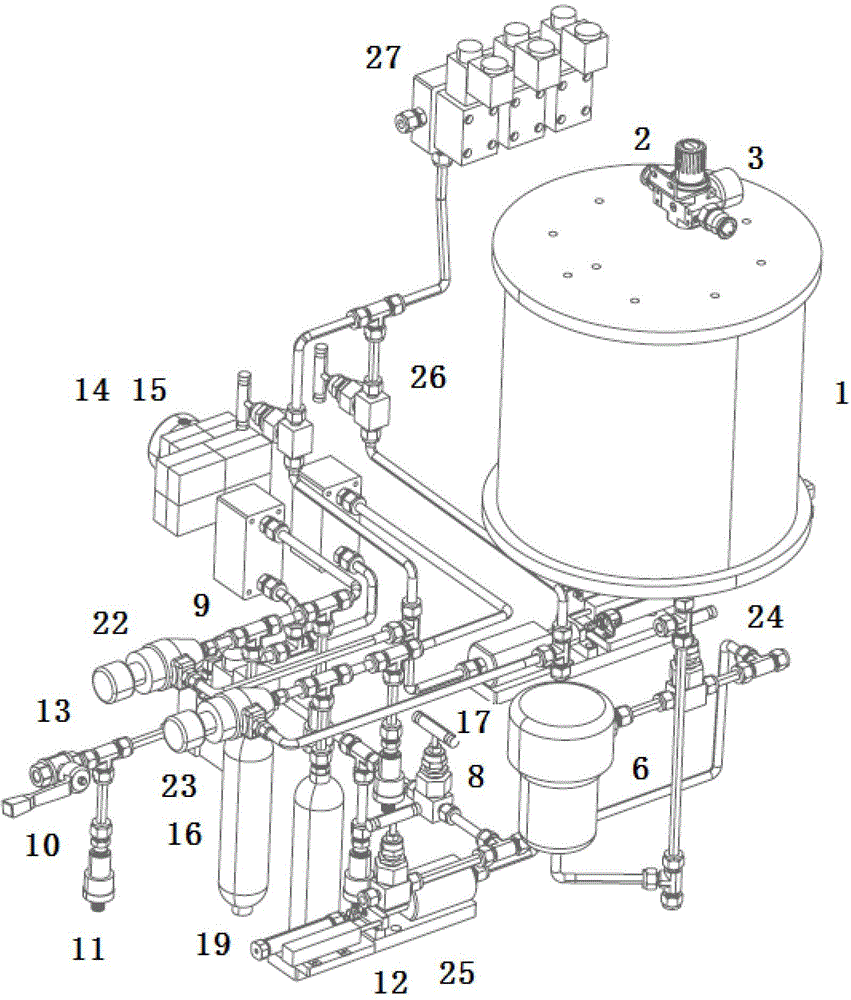

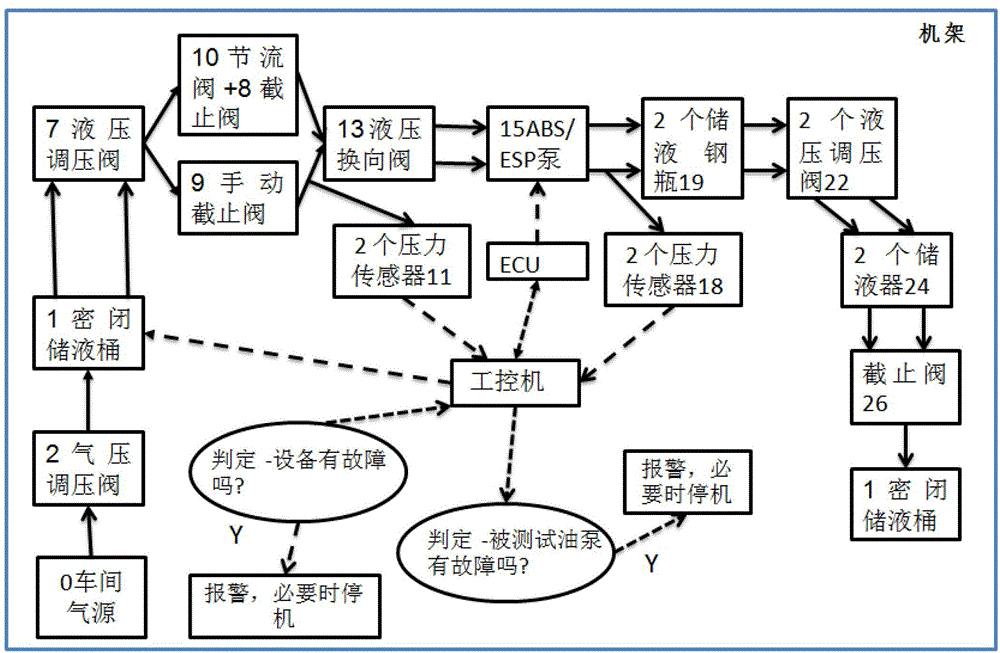

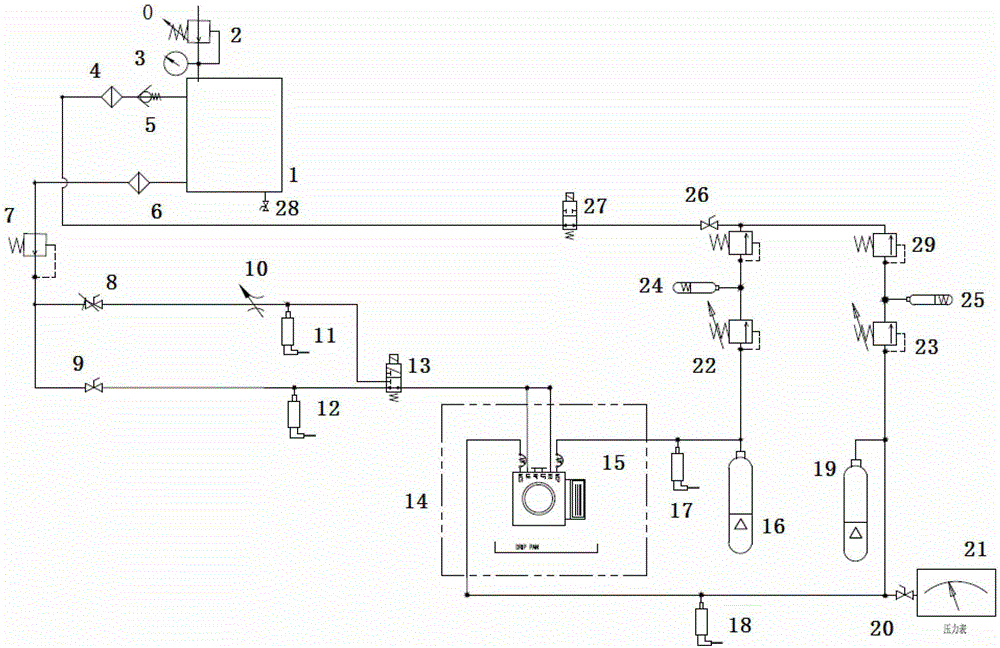

[0043] Attached below figure 1 , 2 , 3, 4 and embodiments describe the present invention in detail

[0044] The testing device of ESP / ABS pump of the present invention comprises tested pump unit 15, and each unit comprises 2 oil pumps and 1 driving motor, and tested pump unit 15 is also connected with oil pump oil inlet part; Adjustable oil outlet pressure part ; Flow measurement part and industrial computer part.

[0045] The oil inlet part of the ABS / ESP oil pump can be adjusted (relative pressure -1.0~6.0bar), which is used to simulate the actual oil inlet pressure of the ABS / ESP oil pump. During the braking process, when the ABS oil pump works and participates in the regulation of the brake fluid pressure, the oil pump needs to evacuate the brake fluid from the ABS accumulator. A decompression valve 7 is selected on the board, which is used to adjust the 6Bar hydraulic pressure from the closed liquid storage tank 1 to an ideal range; when the ESP is active during the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com