Anti-icing system and anti-icing control method of inlet lip of engine

A control method and anti-icing system technology, applied in the direction of machines/engines, mechanical equipment, jet propulsion devices, etc., can solve the problems of reduced air intake area, impact on flight safety, damage to engine fan blades, etc., to reduce the amount of bleed air , Reduce the skin temperature and prevent insufficient heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

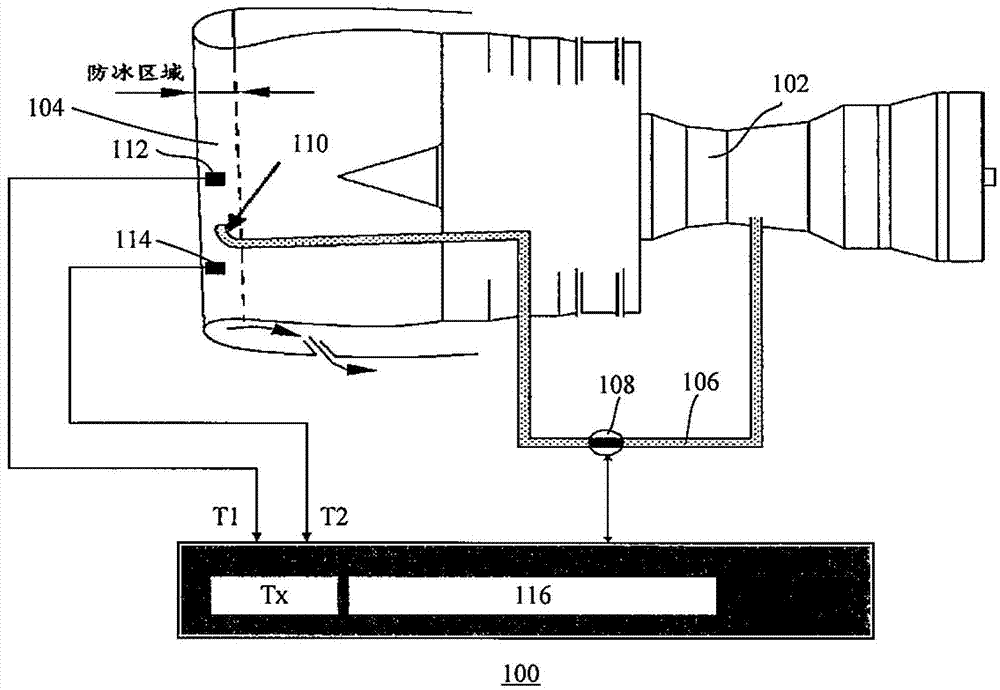

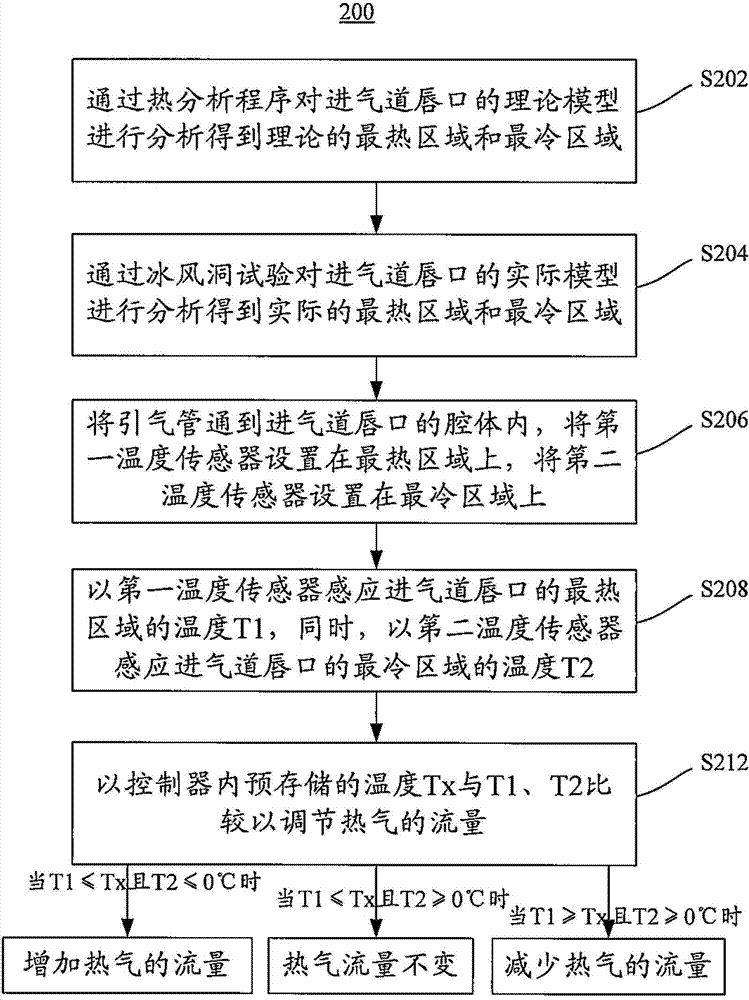

[0024] Such as figure 1 As shown, there is shown an anti-icing system 100 for an intake lip of an engine. The anti-icing system 100 includes a high-pressure compressor 102 , an air inlet 104 , an air induction pipe 106 , a pressure regulation shut-off valve 108 , a swirl nozzle 110 , a first temperature sensor 112 , a second temperature sensor 114 and a controller 116 .

[0025] Specifically, the air inlet end of the air induction pipe 106 is connected to a certain stage of the high-pressure compressor 102 to introduce the hot gas of the high-pressure compressor 102, and the swirl nozzle 110 at its outlet end is arranged on the lip of the air inlet 104 The annular cavity is used to release hot gas so as to prevent ice from forming on the lip of the air intake duct 104 .

[0026] A pressure regulating shut-off valve 108 is arranged on the air induction pipe 106 for adjusting the flow rate of the hot gas in the air induction pipe 106 .

[0027] The first temperature sensor 112...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com