Method for filling bottom of gravelly soil core wall of stone dam

A gravel soil and rockfill dam technology, which is applied in the construction of water retaining structures in water conservancy and hydropower projects, can solve the problems of good fluidity, long construction period, and high clay plasticity, so as to save investment, simplify construction, ensure construction quality and The effect of progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

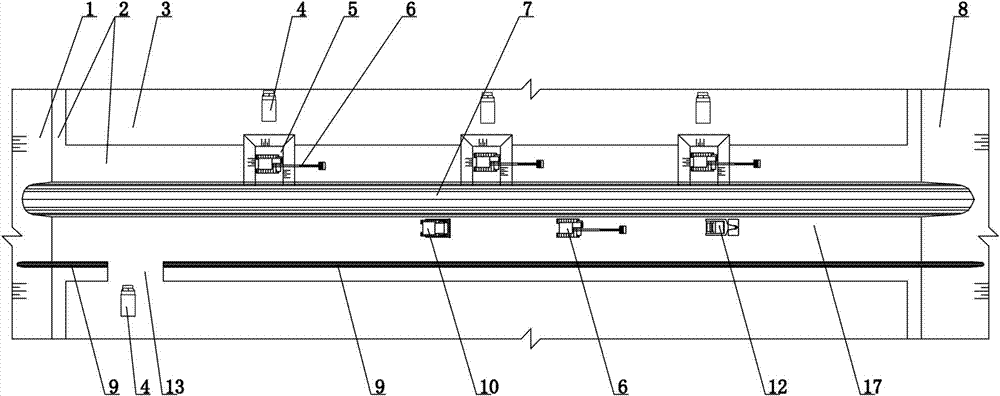

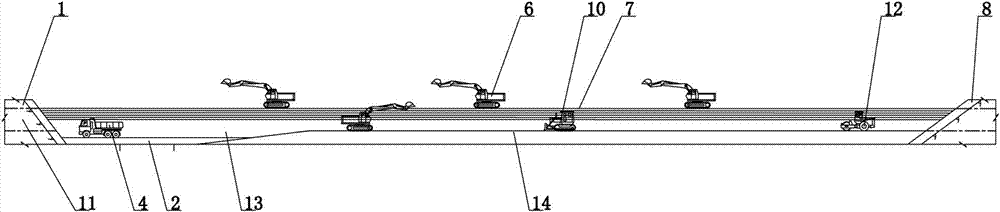

[0025] Such as Figure 1-4 Among them, a method for filling the bottom of the gravel soil core wall of a rockfill dam, including a first cutoff wall 15 and a second cutoff wall 16 arranged on the retaining dam, and the second cutoff wall 16 is located on the downstream side, A concrete corridor 7 is poured on the second anti-seepage wall 16, and the two ends of the concrete corridor 7 are respectively connected with the slope-applied concrete 1 in the core wall area of the left bank slope and the slope-applied concrete 8 in the core wall area of the right bank slope. A grouting flat hole 11 is arranged in the concrete corridor 7, and the height of the concrete corridor 7 is 8-9 meters. On the downstream side of the concrete corridor 7, a horizontal filter layer 18 is also provided, and the gravel soil filling area 3 is formed on the horizontal filter layer 18. Specifically include the following steps:

[0026] One, such as figure 1 , 3 , 4, on the first anti-seepage wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com