Extraction process for hazelnut kernel oil

An extraction process, the technology of hazelnut kernels, which is applied in the direction of fat oil/fat production and fat production, can solve the problems of long time consumption, high energy consumption, low extraction rate, etc., and achieve the effect of short time consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

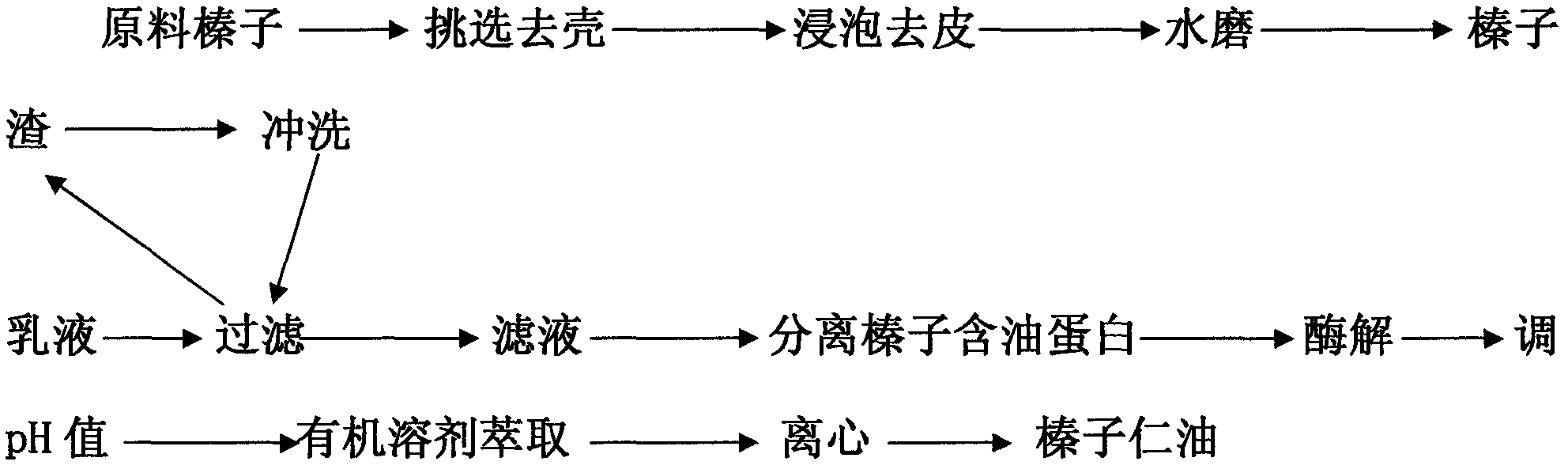

[0018] The present invention utilizes enzymatic hydrolysis to extract hazelnut kernel oil, and the process steps of the present invention are:

[0019] 1. Preparation of Hazelnut Kernel Emulsion

[0020] Crush the peeled hazelnut kernels, soak them in water to make them fully absorb water, and then grind them with water to obtain hazelnut kernel emulsion for enzymolysis;

[0021] 2. NaOH peeling process

[0022] Soak in 3% NaOH lye for 1.5min at 80°C and peel off;

[0023] 3. Enzymatic hydrolysis of protein isolate from hazelnut kernel emulsion

[0024] The hazelnut kernel protein is first separated from the hazelnut kernel emulsion, and then the hazelnut kernel protein isolate is subjected to enzymatic extraction and oil extraction. The enzymatic hydrolysis time is 1-2 hours, the enzymatic hydrolysis temperature is 45-55°C, and the pH value is 6.5-7.5. The amount of enzyme added is 200-1500IU / g.

[0025] The enzymatic oil extraction process is to add enzymes on the basis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com