Nitride fluorescent powder and preparation method thereof, luminescent device containing fluorescent powder

A technology of nitride phosphors and phosphors, which is applied in the direction of chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of demanding equipment, complicated process, and high cost, and achieve easy operation, high luminous efficiency, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

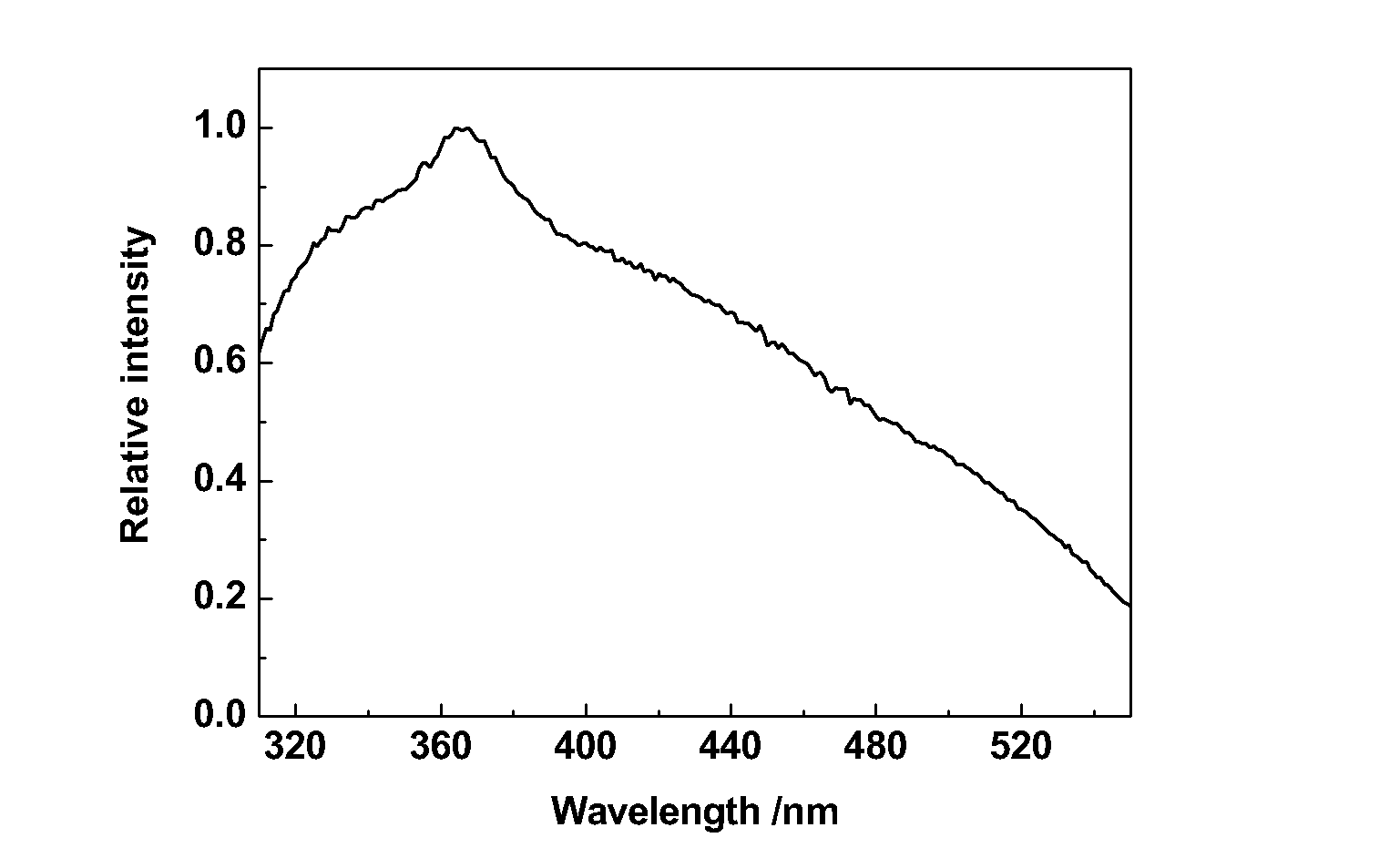

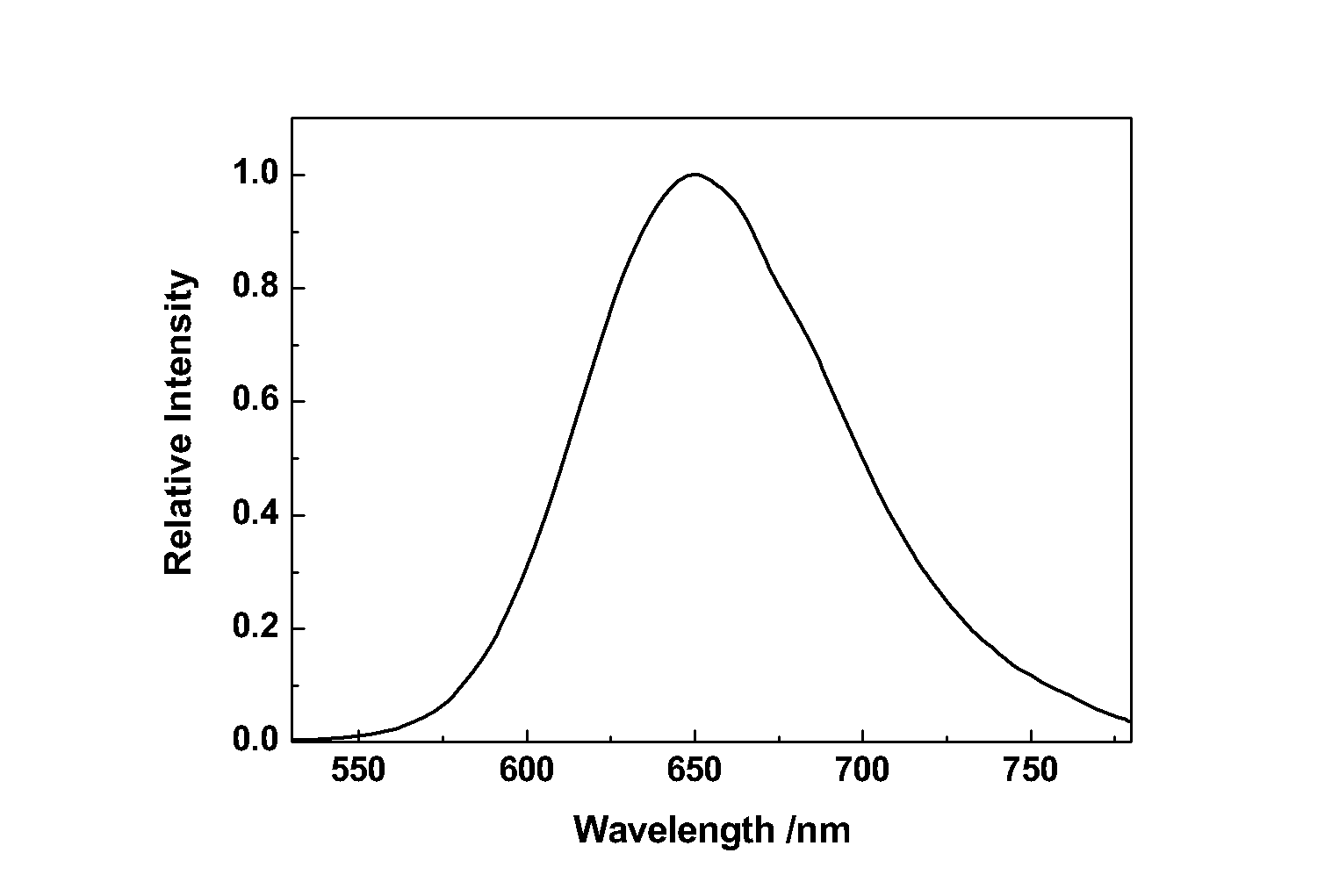

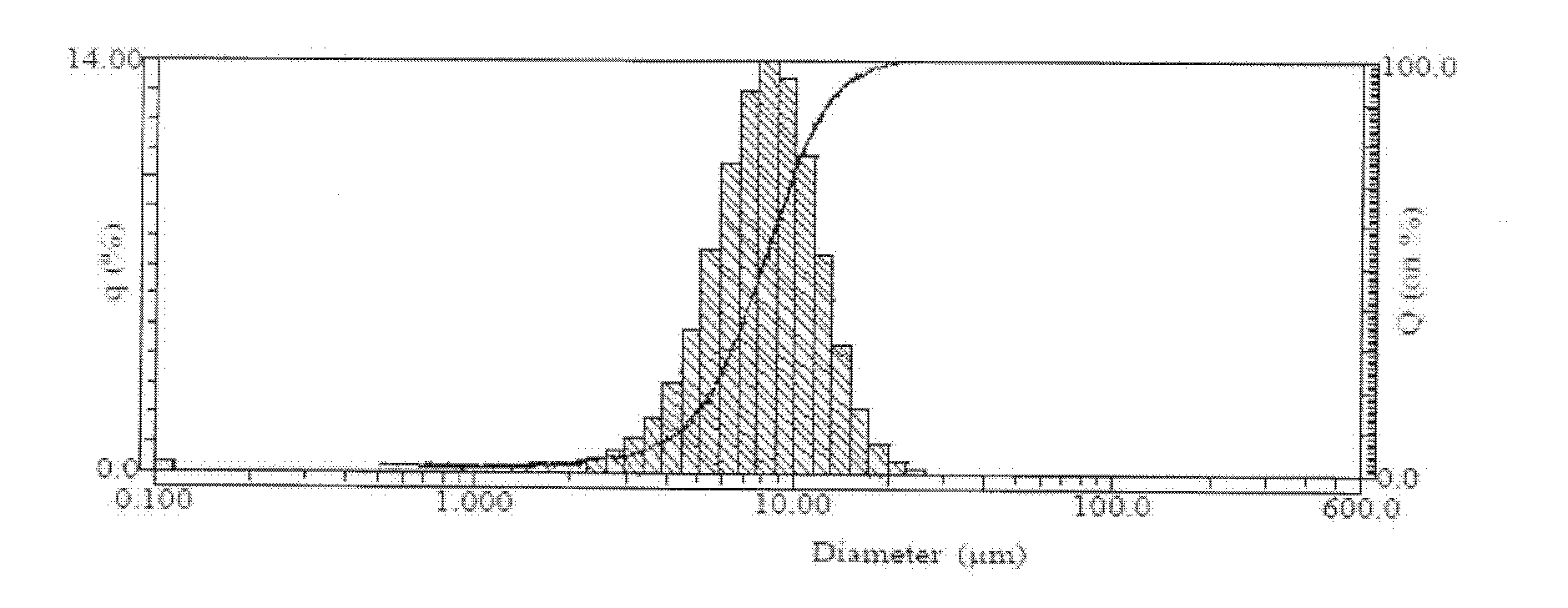

[0038] The nitride red phosphor product of the present embodiment, after analyzing the chemical formula of this phosphor is Ca 2.9915 (N 1.999 , O 0.001 )·3.0Al 0.9997 (N 0.999 , O 0.001 )·1.0Si 2.9998 (N 3.999 , O 0.001 )·0.0001Se 1.8 N 2.4 :0.008Eu. The manufacturing method is to weigh silicon nitride (4N), aluminum nitride (4N), calcium nitride (4N), europium nitride (4N), selenium nitride (4N) and metal calcium according to the stoichiometric ratio, and mix Evenly, the mixed raw materials are kept at 1500°C for 3 hours under a nitrogen-hydrogen atmosphere, and then the temperature is lowered to below 100°C. After taking them out, they are subjected to post-processing such as grinding, washing, drying, and sieving. The average particle size of the obtained phosphor is 10 μm, and its excitation spectrum is as follows figure 1 As shown, it can be seen from the figure that there is strong absorption from 325nm to 500nm, which is suitable for ultraviolet, near ultrav...

Embodiment 2

[0040] The nitride red phosphor product of the present embodiment, after analyzing the chemical formula of this phosphor is Ca 2.9915 (N 1.999 , O 0.001 )·3.0Al 0.9997 (N 0.999 , O 0.001 )·1.0Si 2.9998 (N 3.999 , O 0.001 )·0.001Se 1.8 N 2.4 :0.008Eu. Weigh silicon nitride (4N), aluminum nitride (4N), calcium carbonate (4N), europium oxide (4N) and elemental selenium (4N) according to the stoichiometric ratio, and fully mix them uniformly. Its manufacturing method and post-treatment process are basically the same as in Example 1. The color coordinates and relative luminous intensity of the obtained phosphor powder are shown in Table 1.

Embodiment 3

[0042] The nitride red phosphor product of the present embodiment, after analyzing the chemical formula of this phosphor is Ca 2.9915 (N 1.999 , O 0.001 )·3.0Al 0.9997 (N 0.999 , O 0.001 )·1.0Si 2.9998 (N 3.999 , O 0.001 )·0.01Se 1.8 N 2.4 :0.008Eu. Weigh silicon nitride (4N), aluminum nitrate (4N), calcium hydroxide (4N), metal europium (4N) and selenium oxide (4N) according to the stoichiometric ratio, and mix well and evenly. Its manufacturing method and post-treatment process are basically the same as in Example 1. The color coordinates and relative luminous intensity of the obtained phosphor powder are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com