High-efficiency N/P flame retardant, as well as preparation method and application thereof

A technology of nitrogen-phosphorus flame retardants and flame retardants, applied in the field of high-efficiency nitrogen-phosphorus flame retardants and their preparation, to achieve the effect of simplifying process steps and improving flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

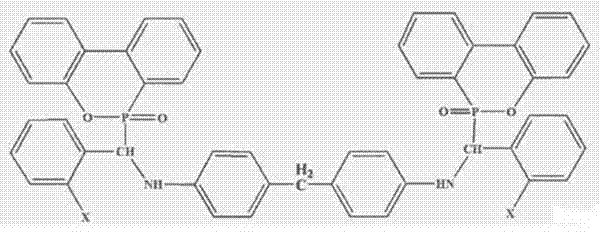

Image

Examples

Embodiment 1

[0022] flame retardant ( 1 ) The synthetic steps are as follows:

[0023] Add 9.91g of DDM, 10.61g of benzaldehyde and about 82.08g of absolute ethanol into a three-necked flask with a stirring device. Under stirring, the reaction temperature is 0 o C is reacted for 2-4h, and the mixture A is obtained after the reaction is completed;

[0024] Then, 21.62 g DOPO was added to the mixture A in the three-necked flask, and under stirring, the temperature of reaction was 0 o C was reacted for 18 h. After the reaction was finished, the final mixture was suction-filtered, washed, and dried in a vacuum oven for 60 o C drying for 8 h to obtain the required flame retardant ( 1 ), the yield is 89.2%.

[0025] flame retardant ( 1 ) test analysis results are as follows:

[0026] 1 H HMR (ppm, DMSO-d 6 ), δ=3.45(H 1’ ), 4.08(H 1 ), 5.01-5.10 (H 6 ), 5.48-5.58 (H 6’ ), 6.10 (NH’), 6.50-6.60 (H 4 , H 4’ , NH), 6.60-6.68 (H 3 , H 3’ ), 7.05 (H 21 ), 7.20 (H 21’ ), 7,25-7.35 (H...

Embodiment 2

[0030] flame retardant ( 2 ) The synthetic steps are as follows:

[0031] Add 9.91g of DDM, 12.21g of 2-hydroxybenzaldehyde and about 884.8 g of ethyl acetate into a three-necked flask with a stirring device. Under stirring, the reaction temperature is 20 o C was reacted for 2-4 h to obtain mixture A;

[0032] Then, 21.62 g DOPO was added to the mixture A in the three-necked flask, and under stirring, the temperature of reaction was 50 o C was reacted for 18h. After the reaction was finished, the final mixture was suction-filtered, washed, and dried in a vacuum oven for 60 oC Dry for 8 h to get the required flame retardant ( 2 ), the yield was 90.7%.

[0033] flame retardant ( 2 ) test analysis results are as follows:

[0034] 1 H HMR (ppm, DMSO-d 6), δ=3.45(H 1’ ), 4.08(H 1 ), 5.23 (H 6 ), 5.38(H 6’ ), 6.12 (NH’), 6.40-6.60 (H 4 , H 4’ , H 11 , H 11’ , H 9 , H 9’ , NH), 6.70-6.80 (H 3 , H 3’ , H 8 , H 8’ ), 6.95 (H 23 , H 10 ), 7.09 (H 10’ ), 7.13(H ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com