Rock soil similar material and preparation method thereof

A technology of rock-soil similarity and mixed materials, which is applied in the field of rock-soil similar materials and their preparation, can solve the problems of not considering the influence of material friction characteristics, difficulty in making continuous and uniform models, low density of quartz sand, etc., and achieve strength parameters The effects of wide range of variation, easy molding, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A kind of preparation method of geotechnical similar material, described preparation method is carried out according to the following steps:

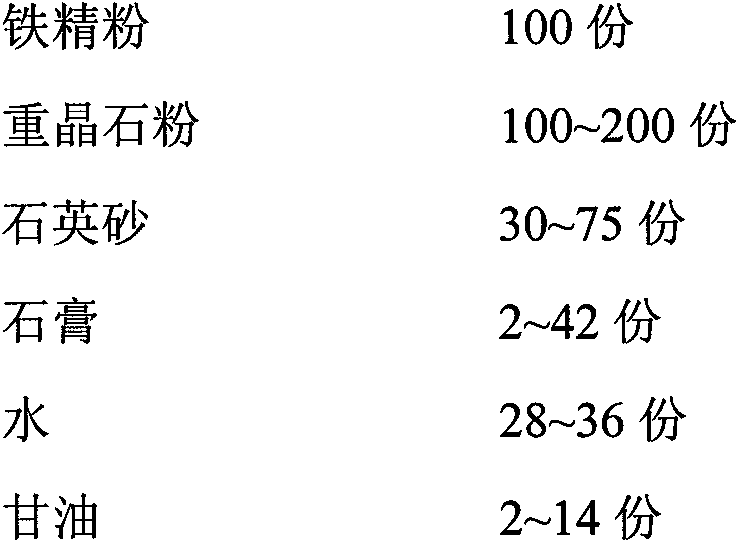

[0030] a each material component is respectively by mass part ratio:

[0031]

[0032] Weigh each raw material separately.

[0033] b. Put the iron fine powder, barite powder, quartz sand and gypsum weighed according to the mass ratio into the mixing basin, and stir well to form a dry mixture. The lumps can be sifted through a small sieve to remove lumps.

[0034] c. Add water and glycerin weighed according to the mass part ratio to the uniformly stirred dry mixture, and further stir evenly to form a wet mixture.

[0035] d Pour the well-mixed wet mixture into the rigid mold, and carry out layered tamping. After each layer is tamped, use a thin iron rod to roughen the interface formed by the tamping.

[0036] e Remove the rammed damp mixture to form a rock-soil-like material test piece. When demoulding, first remove the mol...

Embodiment 1

[0038] The mass ratio of each component of similar materials is:

[0039]

[0040] Its preparation method is carried out according to the above steps.

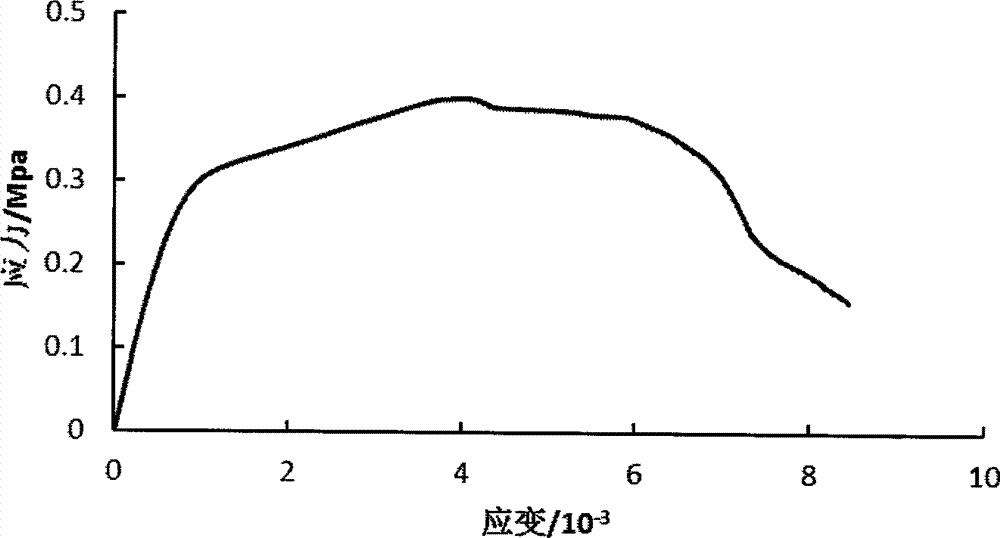

[0041] The physical and mechanical property index of gained similar material is as follows:

[0042]

[0043] In this example, due to the low content of gypsum, the strength indexes of the obtained similar materials are relatively small; due to the high content of fine iron powder, the obtained similar materials have relatively high density.

Embodiment 2

[0045] The mass ratio of each component of similar materials is:

[0046]

[0047] Its preparation method is carried out according to the above steps.

[0048] The physical and mechanical property index of gained similar material is as follows:

[0049]

[0050] In this example, due to the large content of gypsum, the strength indexes of the obtained similar materials are relatively large; due to the small content of fine iron powder, the density of the obtained similar materials is small; the content of coarse aggregate quartz sand is large, and the obtained The friction angle of similar materials is larger; the content of glycerin is higher, and the deformation modulus of similar materials obtained is smaller.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com