Inorganic foam material for joint sealing of wall thermal insulation system and preparation method of inorganic foam material

A thermal insulation system and inorganic foam technology, applied in applications, household appliances, ceramic products, etc., can solve the problems of high thermal conductivity, poor fire resistance, fire safety hazards, etc., achieve a simple preparation method, overcome poor fire resistance, and meet the use requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

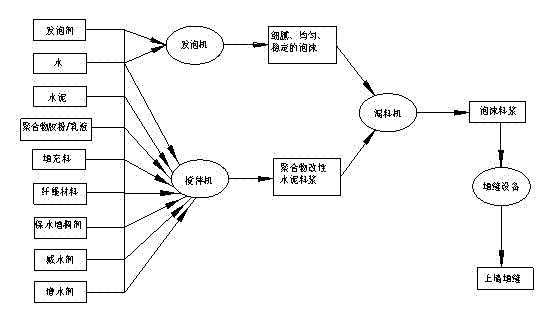

[0036] In this example, an inorganic foam material for wall insulation system caulking uses polymer modified cement slurry as the base material, introduces an appropriate amount of fine, uniform and stable foam through physical foaming, and adds various properties at the same time The conditioner is prepared as a foam material for joint filling in the wall insulation system, and the foam slurry is directly injected into the joints of the wall boards by using ordinary joint filling equipment during construction.

[0037] The invention relates to an inorganic foam material for caulking of a wall thermal insulation system, which is composed of 1 part of foam and 3 parts of polymer modified cement slurry.

[0038] Described foam comprises the raw material of following parts by weight:

[0039] 1 part plant-based foaming agent

[0040] 20 parts water

[0041] The polymer modified cement slurry includes the following raw materials in parts by weight:

[0042] 500 parts Portland c...

Embodiment 2

[0055] The difference between this example and Example 1 lies in the composition of raw materials and their proportioning ratio. An inorganic foam material for joint filling in a wall insulation system is composed of 1 part of foam and 10 parts of polymer-modified cement slurry.

[0056] Described foam comprises the raw material of following parts by weight:

[0057] 1 part animal-based foaming agent

[0058] 50 parts water

[0059] The polymer modified cement slurry includes the following raw materials in parts by weight:

[0060] 400 parts of fast-hardening sulfoaluminate cement, 300 parts of P·O 42.5R cement

[0061] 300 parts magnesium hydroxide filler

[0062] 10 parts vinyl acetate-ethylene copolymer rubber powder

[0063] 15 parts 3-10mm long alkali-resistant fiberglass

[0064] 15 parts hydroxyethyl methylcellulose ether

[0065] 50 parts of naphthalene series superplasticizer

[0066] 5 parts silicone water repellent

[0067] 600 parts water

[0068] The prep...

Embodiment 3

[0073] The difference between this example and Example 1 lies in the composition of raw materials and their proportioning ratio. An inorganic foam material for joint filling in a wall insulation system is composed of 1 part of foam and 20 parts of polymer-modified cement slurry.

[0074] Described foam comprises the raw material of following parts by weight:

[0075] 1 part compound foaming agent

[0076] 80 parts water

[0077] The polymer modified cement slurry includes the following raw materials in parts by weight:

[0078] 300 parts Portland cement, 600 parts aluminate cement

[0079] 500 parts fly ash filler

[0080] 100 parts vinyl acetate-ethylene copolymer emulsion (VAE emulsion)

[0081] 30 parts 3-10mm long basalt fiber

[0082] 30 parts hydroxypropyl methylcellulose ether

[0083] 100 parts of sulfamic acid superplasticizer

[0084] 10 parts calcium stearate

[0085] 1000 parts water

[0086] The preparation method of the inorganic foam material for joint ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com