Cultivation method of anammox granular sludge

A technology of anaerobic ammonium oxidation and aerobic granular sludge, which is applied in the field of water treatment, can solve the problems of high-efficiency anaerobic ammonium oxidation granular sludge cultivation difficulties and long cultivation time, and achieve accelerated enrichment growth, enrichment cultivation and The effect of increasing the removal rate of nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: the cultivation method of anammox granular sludge in the present embodiment is carried out according to the following steps:

[0015] Step 1. Inoculate aerobic granular sludge and anammox seed sludge into the EGSB reactor at the same time. The sum of the volume of aerobic granular sludge and anammox seed sludge accounts for 28%~35% of the total volume of the reactor , the volume ratio of aerobic granular sludge and anammox seed sludge is 1: (2.0-2.3);

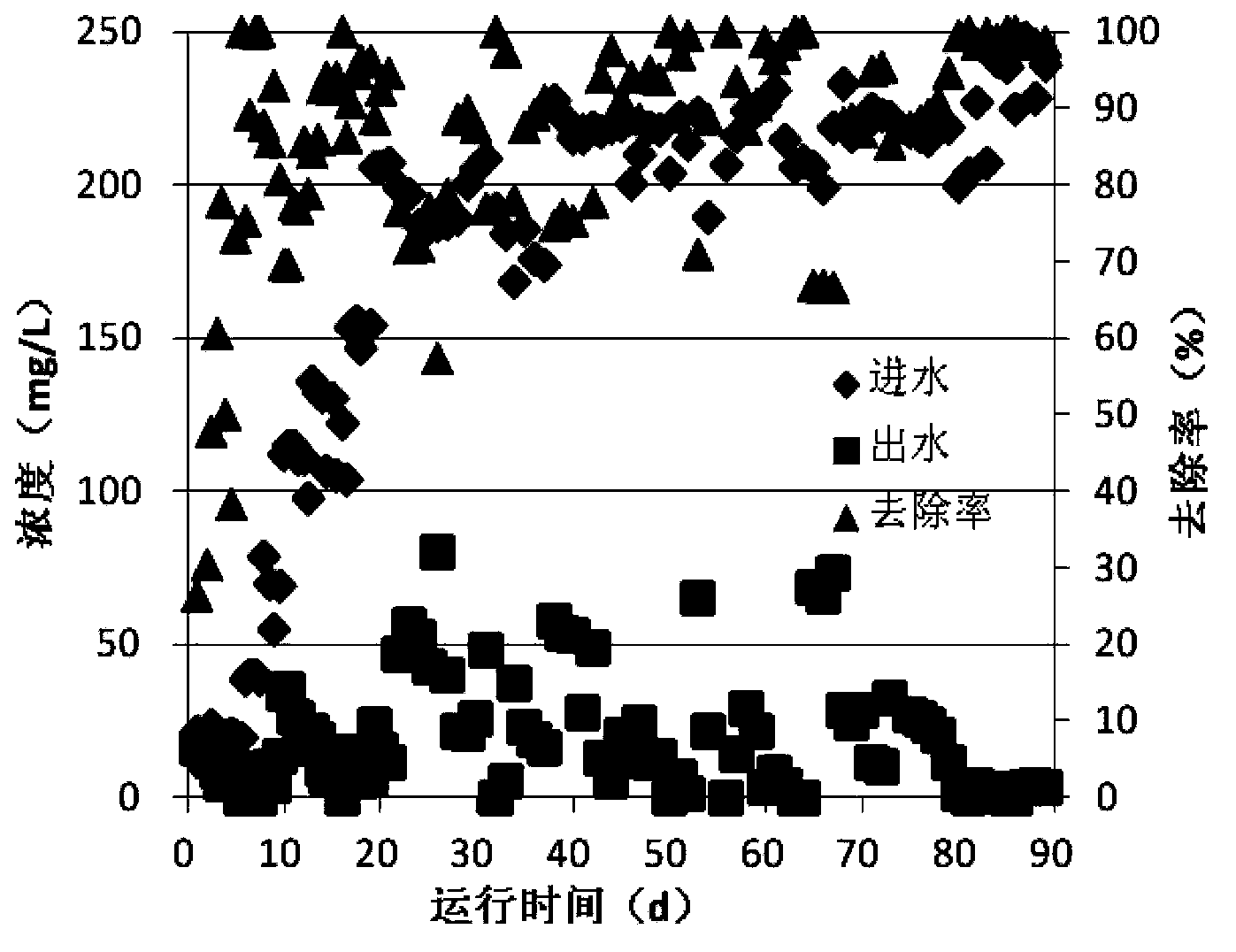

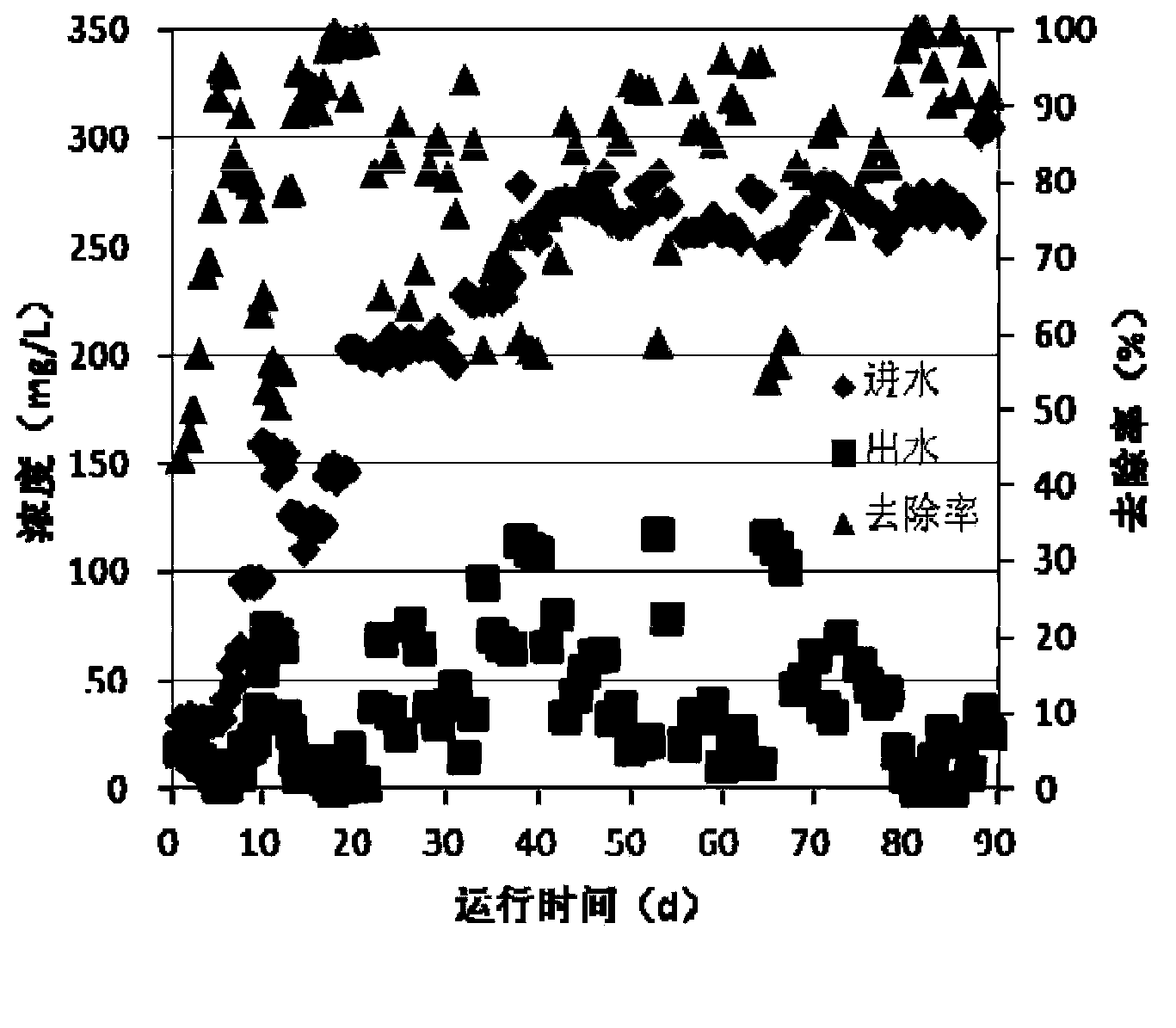

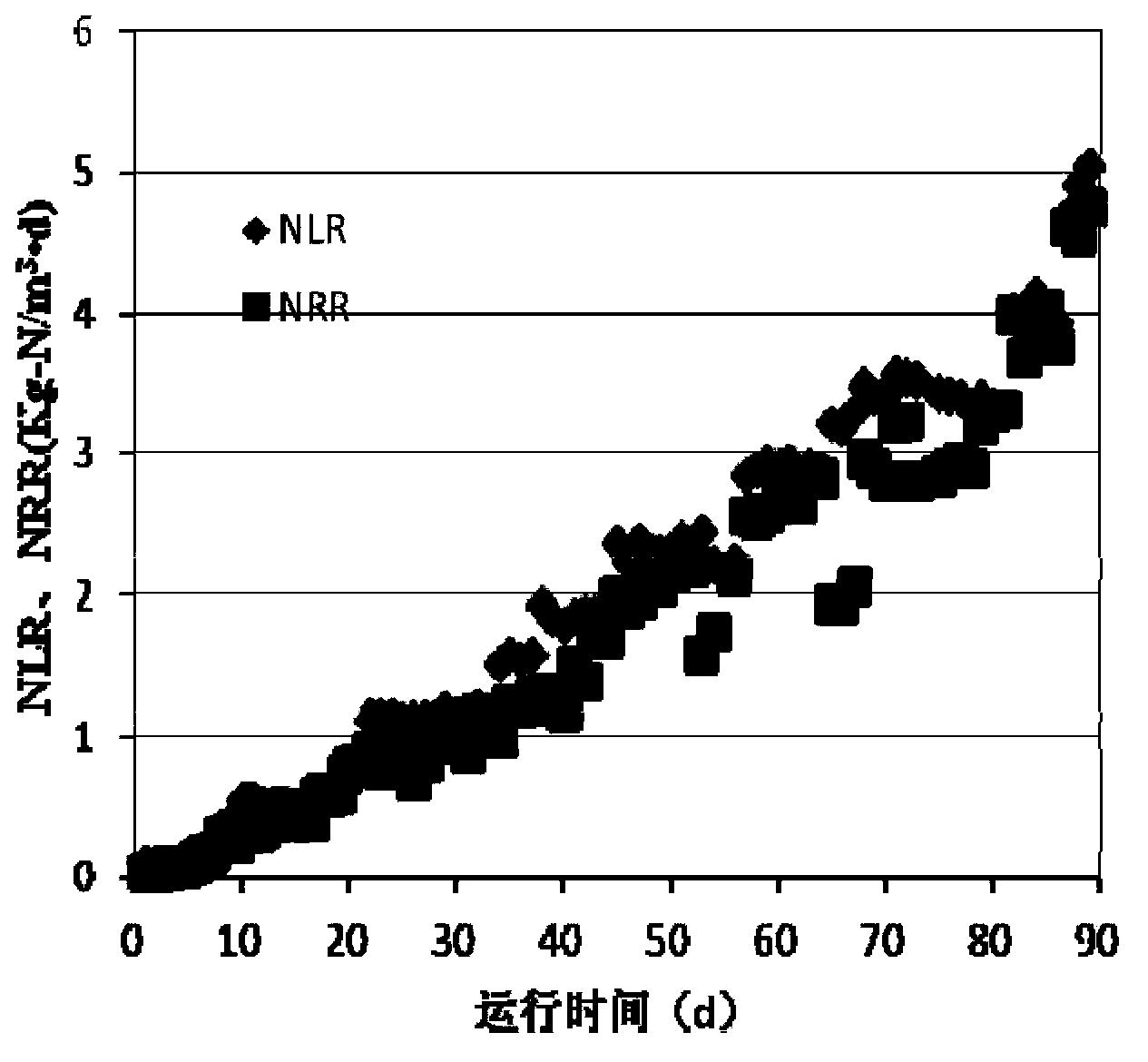

[0016] Step 2. Pass nitrogen-containing simulated wastewater with a dissolved oxygen concentration of 0-0.8mg / L and a pH value of 7.5-8.3 into the EGSB reactor at an ascending flow rate of 3.0m / h, operate at 30-35°C, and control HRT is 12h; detect the concentration of ammonia nitrogen in the influent and effluent of the EGSB reactor, keep the hydraulic retention time at 12h, and gradually increase the ammonia nitrogen and nitrite in the nitrogen-containing simulated wastewater when the simultaneo...

specific Embodiment approach 2

[0019] Specific embodiment two: the difference between this embodiment and specific embodiment one is: KHCO in the nitrogen-containing simulated wastewater 3 The concentration is 1000mg / L, KH 2 PO 4 The concentration is 50mg / L, MgSO 4 ·7H 2 The concentration of O is 200mg / L, CaCl 2 2H 2 The concentration of O is 151mg / L, ZnSO 4 ·7H 2 The concentration of O is 430mg / L, CoCl 2 ·6H 2 The concentration of O is 240mg / L, CuSO 4 ·5H 2 O concentration is 250mg / L, H 3 BO 4 The concentration is 14mg / L, MnCl 2 4H 2 The concentration of O is 990mg / L, NaSeO 4 10H 2 The concentration of O is 210mg / L, NiCl·6H 2 The concentration of O is 190mg / L, NaMoO 4 2H 2 The concentration of O is 220 mg / L, the concentration of vitamin B6 hydrochloride is 10 mg / L, the concentration of vitamin B1 hydrochloride is 5 mg / L, the concentration of vitamin B2 is 5 mg / L, and the concentration of niacin is 5 mg / L , the concentration of pantothenic acid is 5mg / L, the concentration of p-aminobenzoi...

specific Embodiment approach 3

[0020] Specific embodiment three: the difference between this embodiment and specific embodiment two is: NH in the nitrogen-containing simulated wastewater described in step one 4 The initial concentration of Cl is 19.5~23.6mg / L, NaNO 2 The initial concentration is 31.3~32.4mg / L. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com