Method for recycling tail gas during thionyl chloride preparation

A technology for recovery of thionyl chloride and tail gas, which is applied in the direction of sulfur and halogen compounds, can solve the problems of backward technology, complicated process, and increased tail gas volume, and achieve the effect of saving alkali for tail gas absorption and eliminating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

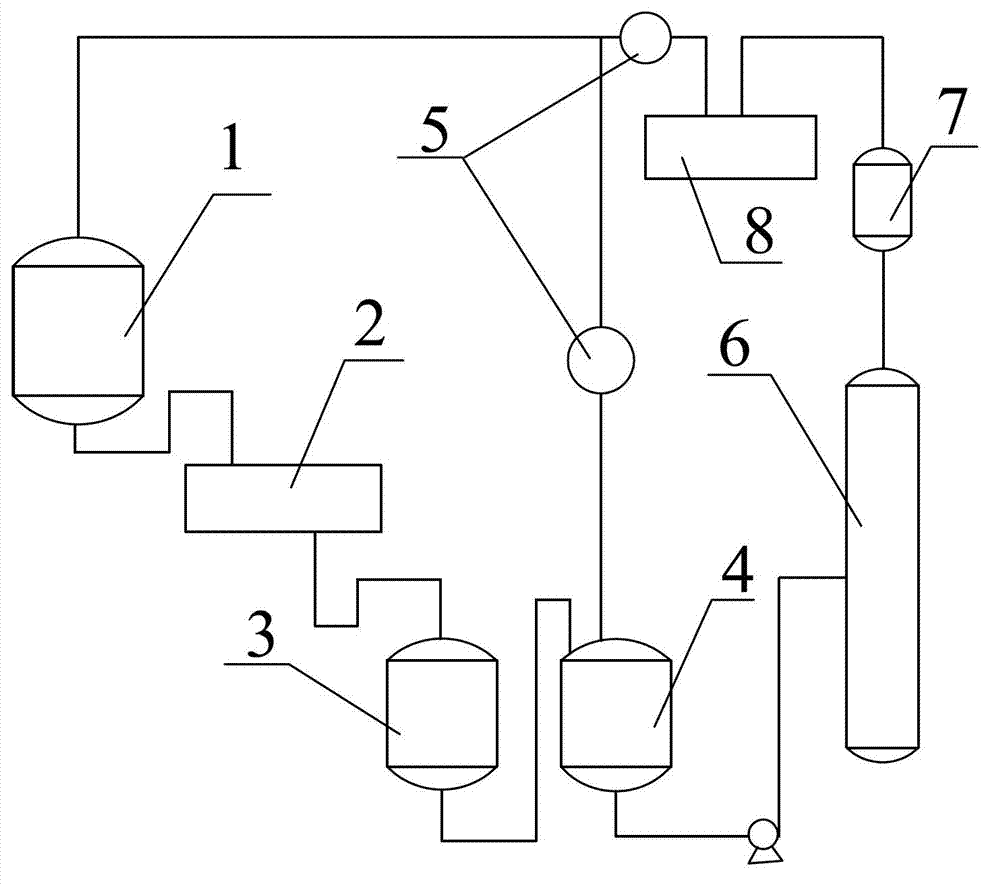

[0046] What this embodiment describes is the method that the gas released during the feeding process from the crude product vulcanization tank 3 to the crude product intermediate tank 4 is transported back to the thionyl chloride synthesis kettle 1 with a liquid ring compressor 5 for recycling, and the produced product is then recycled. After being condensed by the crude product condenser 2, enter the crude product vulcanization tank 3 for recycling, and the specific implementation method is as follows:

[0047] The vaporized chlorine enters the sulfur dichloride synthesis tank after being metered, and the sulfur monochloride from the de-weighting tower tank in the rectification tower 6 (the rectification tower is composed of a de-weighting tower, a dehydrogenation tower and a product tower) After being metered, it also flows into the sulfur dichloride synthesis tank, and chlorine gas and sulfur monochloride react at 83°C at a ratio of 150:0.25 (liquid) to generate sulfur dichl...

Embodiment 2

[0052] What this embodiment describes is in the sulfur oxychloride distillation process, the condensed tail gas is transported back to the method for recycling the thionyl chloride synthesis kettle 1 with a liquid ring compressor 5, and the specific method is as follows:

[0053] In rectification tower 6, the temperature at the bottom of the weight-removing tower is 130°C, the temperature at the top of the tower is 68°C, the reflux ratio is 1:1, and a secondary vulcanization tank is installed at the top of the tower. The rectification liquefaction tail gas condensed by the condenser 8 is pressurized and sent to the thionyl chloride synthesis kettle 1 by a liquid ring compressor 5 . The liquid ring compressor 5 uses sulfur monochloride as the circulating medium, and the frequency conversion controls the pressure inside the tower. The pressure of the weight removal tower in the rectification tower 6 is stable at -200Pa. When adding sulfur to the secondary vulcanization tank 7, th...

Embodiment 3

[0055] What this embodiment describes is the method that after the secondary vulcanization of solid sulfur with a moisture content of 0.48%, the distillation condensed tail gas is recycled to the thionyl chloride synthesis kettle 1 for circular reaction, and the specific method is as follows:

[0056] In the rectifying tower 6, the temperature of the de-weighting tower bottom is 125°C, the temperature at the top of the tower is 71°C, the reflux ratio is 1:1, and a secondary vulcanization tank 7 is installed at the top of the tower. A liquid ring compressor 5 is used to recover the rectification liquefied tail gas under pressure and send it to the thionyl chloride synthesis kettle 1 . The liquid ring compressor 5 uses a mixture of sulfur monochloride and thionyl chloride as the circulating medium, adopts frequency conversion control, and the pressure in the weight removal tower in the rectification tower 6 is stable at -250Pa. The moisture content of the added solid sulfur is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com