A high stiffness and high reflectivity reflective film

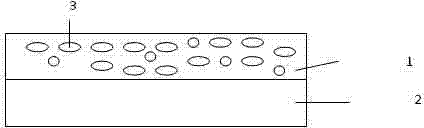

A high reflectivity, reflective film technology, applied in the field of reflective film, can solve the problems that affect the brightness and picture quality of backlight and display, the reflective film is easy to scratch, wrinkle, affect the use and processing, etc., to eliminate tearing phenomenon, improve Production stability and yield, the effect of improving tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Mix polyethylene terephthalate polyester chips with an intrinsic viscosity of 0.65dl / g and masterbatch chips containing titanium dioxide additives evenly so that the final concentration of titanium dioxide particles is 60%, and put the mixed chips at 170°C Crystallize, dry, and then send the crystallized material into the layer A extruder to melt and extrude at 275°C.

[0026] Mix polyethylene terephthalate polyester chips with an intrinsic viscosity of 0.65dl / g and masterbatch chips containing silica additives evenly, crystallize the mixed chips at 170°C, dry, and then crystallize The good material is fed into the B-layer extruder and melted and extruded at 275°C.

[0027] The melt of layer A and layer B is filtered and then enters the double-cavity die and flows to the casting rolls to be cast into amorphous slabs. The thickness ratio of layer A to layer B is 65 / 35, and the cast sheet is longitudinally stretched 2.9 times after longitudinal preheating. Stretch 3.5 t...

Embodiment 2

[0029] Mix polyethylene terephthalate polyester chips with an intrinsic viscosity of 0.65dl / g and masterbatch chips containing silica additives evenly so that the final concentration of silica particles is 55%, and the mixed The slices were crystallized at 170°C, dried, and then the crystallized material was sent to the layer A extruder to be melted and extruded at 275°C.

[0030] Mix polyethylene terephthalate polyester chips with an intrinsic viscosity of 0.65dl / g and masterbatch chips containing silica additives evenly, crystallize the mixed chips at 170°C, dry, and then crystallize The good material is fed into the B-layer extruder and melted and extruded at 275°C.

[0031] The melt of layer A and layer B is filtered and then enters the double-cavity die and flows to the casting rolls to be cast into amorphous slabs. The thickness ratio of layer A to layer B is 70 / 30, and the cast sheet is longitudinally preheated and stretched 2.9 times longitudinally. Stretch 3.5 times...

Embodiment 3

[0033] Mix polyethylene terephthalate polyester chips with an intrinsic viscosity of 0.65dl / g and masterbatch chips containing titanium dioxide additives evenly so that the final concentration of titanium dioxide particles is 45%, and put the mixed chips at 170°C Crystallize, dry, and then send the crystallized material into the layer A extruder to melt and extrude at 275°C.

[0034] Mix polyethylene terephthalate polyester chips with an intrinsic viscosity of 0.65dl / g and masterbatch chips containing silica additives evenly, crystallize the mixed chips at 170°C, dry, and then crystallize The good material is fed into the B-layer extruder and melted and extruded at 275°C.

[0035] The melt of layer A and layer B is filtered and then enters the double-cavity die and flows to the casting rolls to be cast into amorphous slabs. The thickness ratio of layer A to layer B is 25 / 75, and the cast sheet is longitudinally stretched 2.9 times after longitudinal preheating. Stretch 3.5 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com