Slider balance mechanism for full servo notching machine

A technology of balance mechanism and notching machine, which is applied in the direction of stamping machines, presses, manufacturing tools, etc. It can solve the problems that the inertial force of the slider cannot be eliminated and the impact on the precision of the punching sheet can be solved, so as to achieve compact structure, improve production efficiency, and eliminate inertia force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

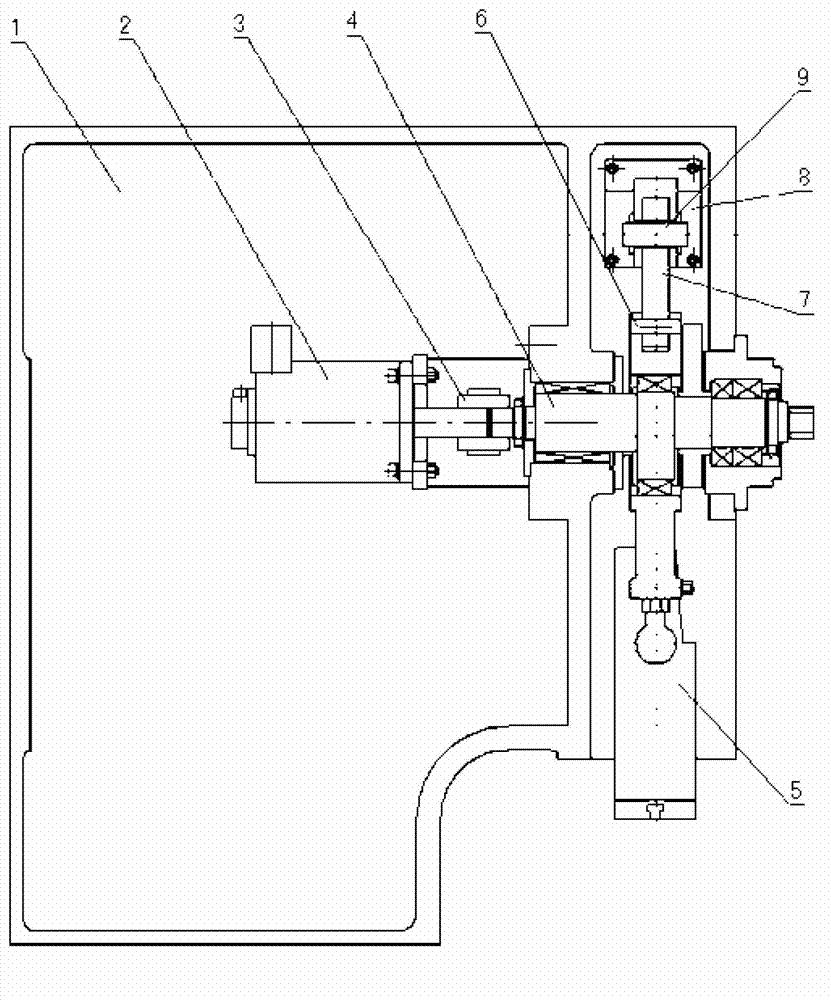

[0011] see figure 1 , used for the slider balance mechanism on the full servo notching machine, including the body 1 of the notching machine, the body 1 of the notching machine is equipped with an AC servo motor 2, a slider part 5, and the output of the AC servo motor 2 The shaft is connected with the eccentric crank shaft 4 through the coupling 3, the slider part 5 is installed on the eccentric crank shaft 4, and the AC servo motor 2 directly drives the eccentric crank shaft 4 to rotate through the coupling 3, so that the slider part 5 Do up and down reciprocating motion to complete the notching process; the body 1 of the notching machine is equipped with a balance body 8, which is connected to the connecting rod block through the swing shaft 9, and the lower end of the connecting rod block is connected to the connecting rod 7 through the small shaft 6 Connection, the lower end of the connecting rod 7 is fixedly installed on the slider part 5.

[0012] The balance body 8 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com