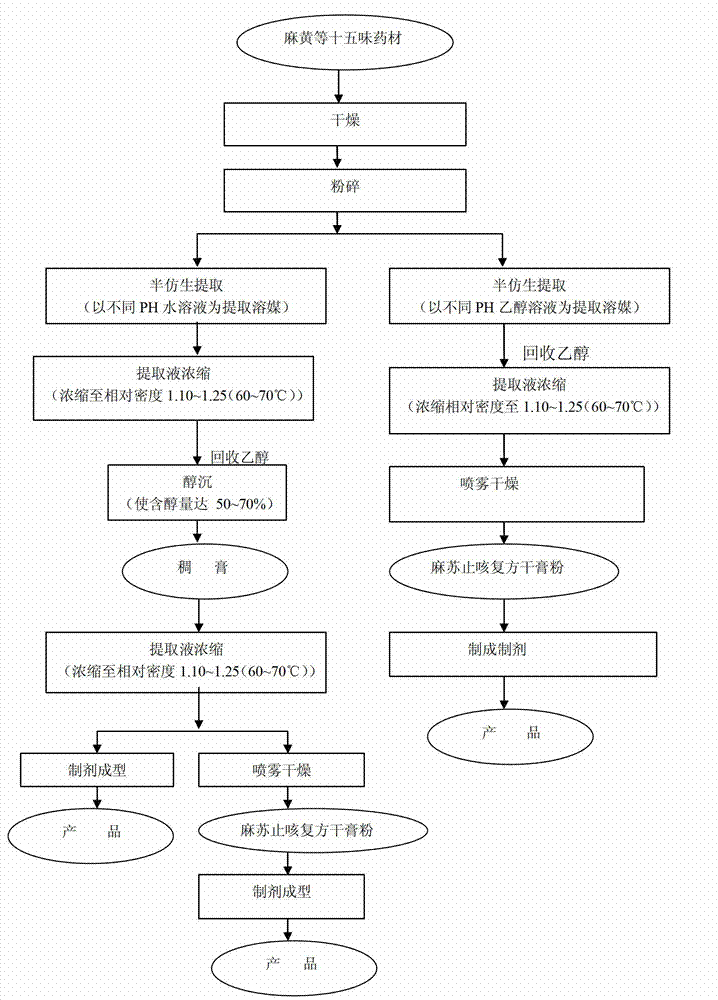

Preparation method of sugar-free Masu anti-cough compound preparation

A compound preparation and sugar-free technology, which can be used in pharmaceutical formulas, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of difficult control of the stability of Masu cough preparations, easy hygroscopicity of sucrose, and high content of sucrose. Achieve the effects of increased contact area, high extraction rate and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1: Preparation of granules

[0060] Heat and reflux extract the fifteen flavors of medicinal materials such as ephedra ephedra for three times. For the first time, use 10 times the weight of the crude powder of the original drug to extract by heating and reflux for 2 hours with a pH value of 2.0, and filter; 2 times the weight of water with a pH value of 7.0, heated and refluxed for 2 hours, and filtered; for the third time, the filter residue was extracted with 8 times the weight of the raw drug coarse powder, heated and refluxed for 2 hours with a pH value of 8.0, and then filtered. The filtrates were combined and concentrated to a clear paste with a relative density of 1.10 (70°C). Add ethanol to the clear paste to make the alcohol content reach 70%, let it stand for 24 hours, filter, recover ethanol, and concentrate to a thick paste with a relative density of 1.20 (70°C). The thick paste was spray dried. During the drying process, the centrifugal speed i...

Embodiment 2

[0061] Example 2: Preparation of granules II

[0062] Heat and reflux extract the fifteen flavors of medicinal materials such as ephedra ephedra for three times. For the first time, use 10 times the weight of the crude powder of the original drug to extract by heating and reflux for 2 hours with a pH value of 2.0, and filter; 2 times the weight of water with a pH value of 7.0, heated and refluxed for 2 hours, and filtered; for the third time, the filter residue was extracted with 8 times the weight of the raw drug coarse powder, heated and refluxed for 2 hours with a pH value of 8.0, and then filtered. The filtrates were combined and concentrated to a clear paste with a relative density of 1.10 (70°C). Add ethanol to the clear paste to make the alcohol content reach 70%, let it stand for 24 hours, filter, recover ethanol, and concentrate to a thick paste with a relative density of 1.20 (70°C). The thick paste was spray dried. During the drying process, the centrifugal spee...

Embodiment 3

[0063] Example 3: Preparation of granules three

[0064] Heat and reflux extract the fifteen flavors of medicinal materials such as ephedra ephedra for three times. For the first time, use 10 times the weight of the crude powder of the original drug to extract by heating and reflux a 60% ethanol solution with a pH value of 2.0 for 2 hours, and filter; Coarse powder 8 times by weight pH value 7.0 concentration 60% ethanol solution heating and reflux extraction for 2 hours, filter; the third time filter residue with 8 times weight of the original drug coarse powder pH value 8.0 concentration 60% ethanol solution heating reflux extraction for 2 hours , filtered; the filtrates were combined, ethanol was recovered, and concentrated to obtain a clear paste with a relative density of 1.15 (70°C); 50 g of sucralose was dissolved in 500 g of 50% ethanol, mixed with the clear paste, and spray-dried, and the drying process was controlled: The centrifugal speed is 15000 rpm, the spray p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com