Processing method of frozen abalone

A processing method and abalone technology, applied in the field of frozen aquatic products, can solve problems such as inedibility, poor water retention, and rough meat quality, and achieve the effects of high-quality taste, high yield, and increased market sales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

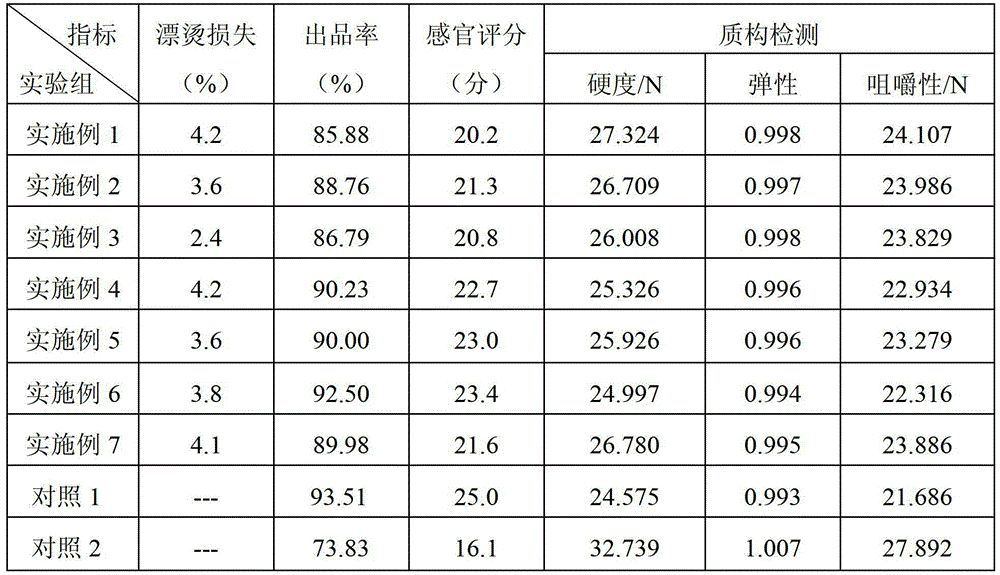

Examples

Embodiment 1

[0024] (1) Cleaning abalone: Wash the fresh abalone with shell and wrinkled plate in tap water with a soft brush to remove the abalone shell, abalone muscle, and the sediment and sundries in the gap between the shell and the muscle, as well as the dirt on the surface of the abalone. black mucous membrane;

[0025] (2) Blanching pretreatment: put the washed abalone into a blanching container filled with a large amount of water at a temperature of 50°C, and blanching for 5 minutes at a constant temperature;

[0026] (3) Cooling: Take out the blanched abalone, drain the surface water, place in the cooling room, and cool until the surface temperature of the abalone is 4°C;

[0027] (4) Quick-freezing: place the cooled abalone at the entrance of the conveyor-type tunnel freezer, set the inlet and outlet temperatures of the freezer to -39°C, and the wind speed to be between 8 and 10m / s to start freezing. -Constantan thermocouples measure the core temperature of the abalone muscle...

Embodiment 2

[0029] (1) Cleaning the abalone: put the sucker of the fresh abalone with the wrinkled plate with the shell facing up, use the abalone meat knife to shovel off the abalone muscles from the abalone shell, remove the internal organs, put the abalone muscles in sea water and wash them with soft hair Clean with a brush to remove the silt, sundries on the abalone muscles and the black mucous membrane on the abalone body surface;

[0030] (2) Blanching pretreatment: put the washed abalone into a blanching container filled with a large amount of water at a temperature of 60°C, and blanching for 3.5 minutes at a constant temperature;

[0031] (3) Cooling: Take out the blanched abalone, drain the surface water, place in the cooling room, and cool until the surface temperature of the abalone is 8°C;

[0032] (4) Quick-freezing: Place the cooled abalone at the entrance of the conveyor-type tunnel freezer, set the temperature of the inlet and outlet of the freezer to -40°C, and the wind...

Embodiment 3

[0034] (1) Cleaning the abalone: put the sucker of the fresh abalone with the wrinkled plate with the shell facing up, use the abalone knife to shovel off the abalone muscle from the abalone shell, remove the viscera, put the abalone muscle in tap water and wash it with soft hair Clean with a brush to clean the sediment and sundries on the abalone muscles and the black mucous membrane on the abalone body surface;

[0035] (2) Blanching pretreatment: Put the washed abalone into a blanching container filled with a large amount of water at a temperature of 80°C, and blanching for 1 minute under constant temperature conditions;

[0036] (3) Cooling: Take out the blanched abalone, drain the surface water, place in the cooling room, and cool until the surface temperature of the abalone is 15°C;

[0037](4) Quick-freezing: place the cooled abalone at the entrance of the conveyor-type tunnel freezer, set the inlet and outlet temperatures of the freezer to -39°C, and the wind speed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com