Method for producing starting material for sintering

A manufacturing method and technology of raw materials, which are applied in the field of manufacturing raw materials for sintering, can solve the problems of reduced granulation strength, reduced usage, and uneven firing of granulators, and achieve the advantages of suppressing scattering, increasing particle size, and easy handling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

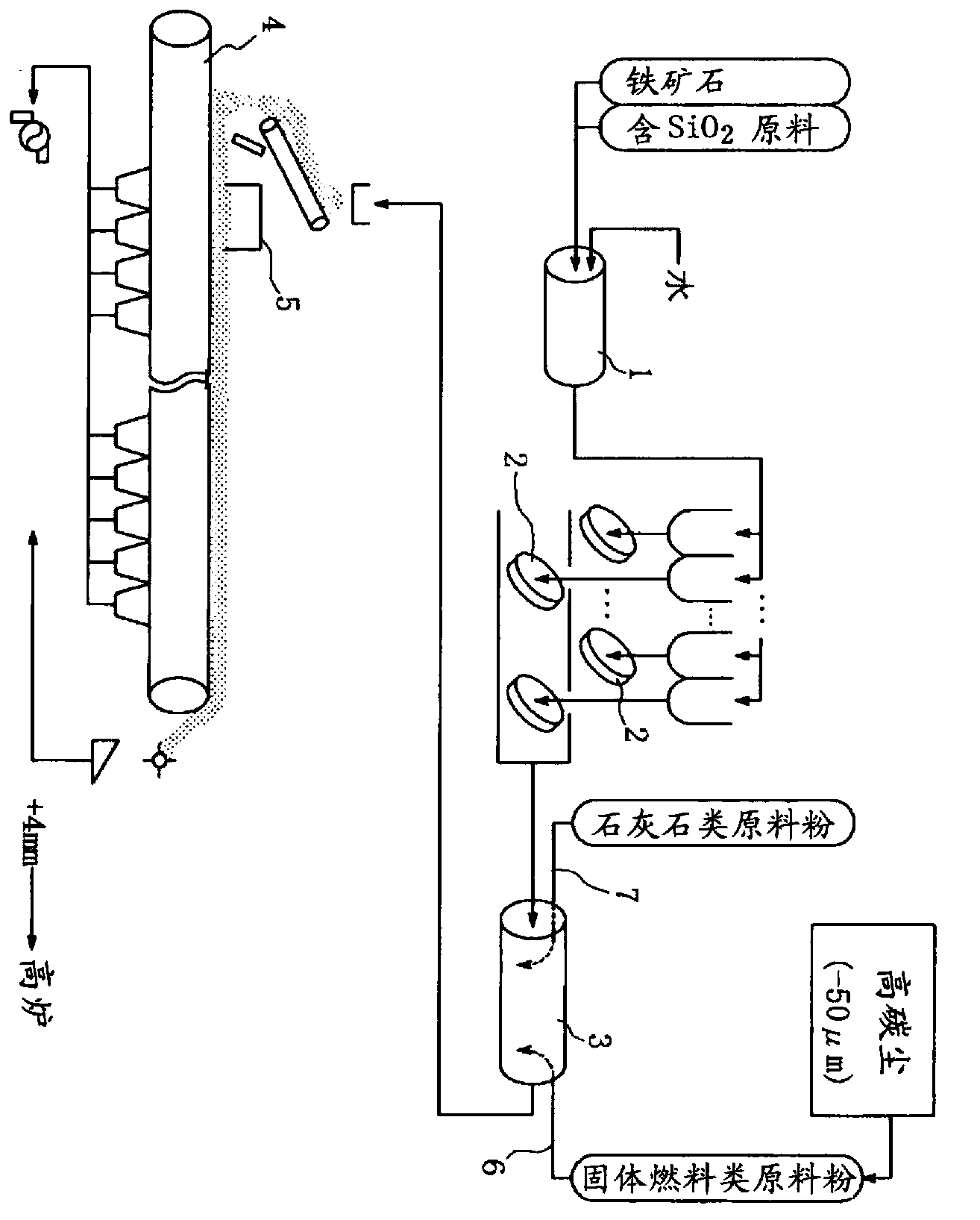

[0132] Such as figure 2 As shown, iron ore and SiO-containing 2 Raw materials are charged into the tumble mixer 1 for agitation and mixing from the charging port to produce mixed raw materials. It should be noted that, as a SiO-containing 2 As the raw material, silica or nickel slag was used. Next, the mixed raw material is charged into the pan granulator 2, and granulated in the pan granulator 2 to obtain quasi-particles. Next, the obtained quasi-particles were packed into the tumble mixer 3 for outer layer formation, and the residence time until the quasi-particles reached the outlet of the tumble mixer 3 for outer layer formation was 40 seconds. Limestone-based raw material powder with an average particle diameter of 1.2 mm is 10% by mass of limestone, and the residence time until it reaches the discharge port of the tumble mixer 3 for outer layer formation is 20 seconds. Added as a solid fuel-based raw material 4% by mass of coke powder with an average particle diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com