Preparation method of lithiumsulphur battery positive pole material

A cathode material, lithium-sulfur battery technology, used in battery electrodes, circuits, electrical components, etc., can solve problems such as inability to uniformly cover active materials, battery capacity decay too fast, and inability to form conductive networks, etc. Achieve selective distribution, solve the effect of poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

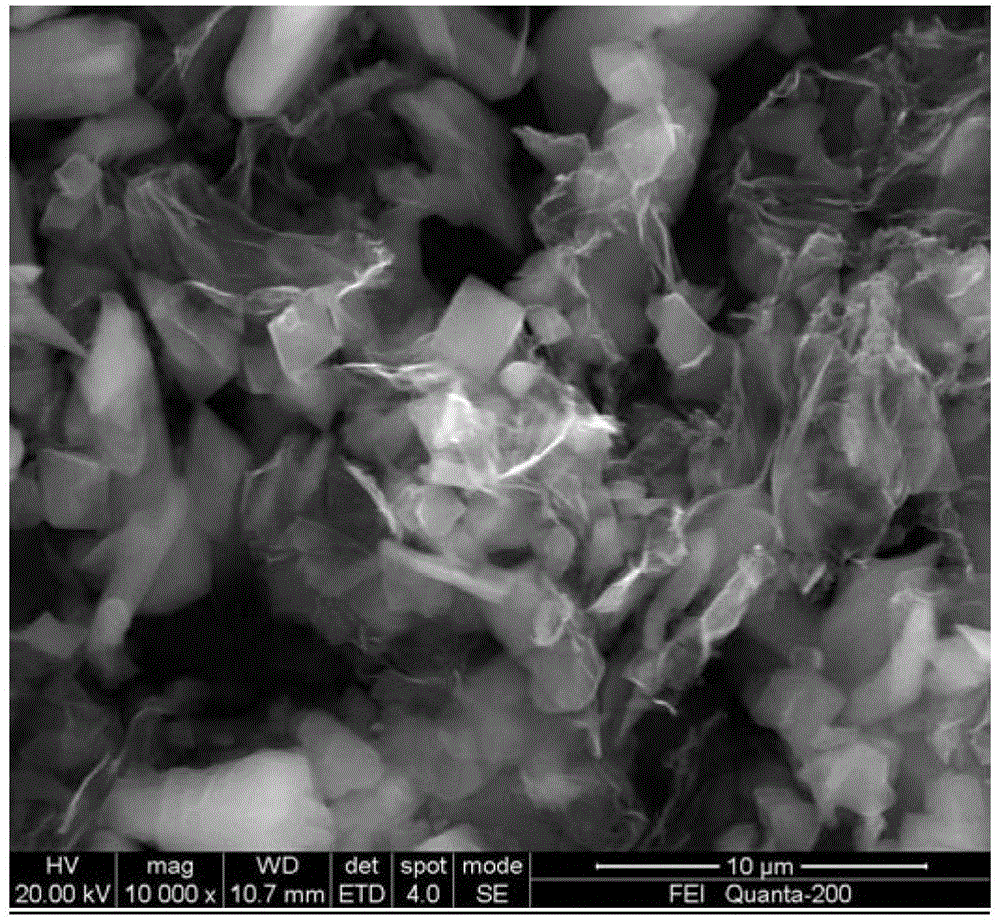

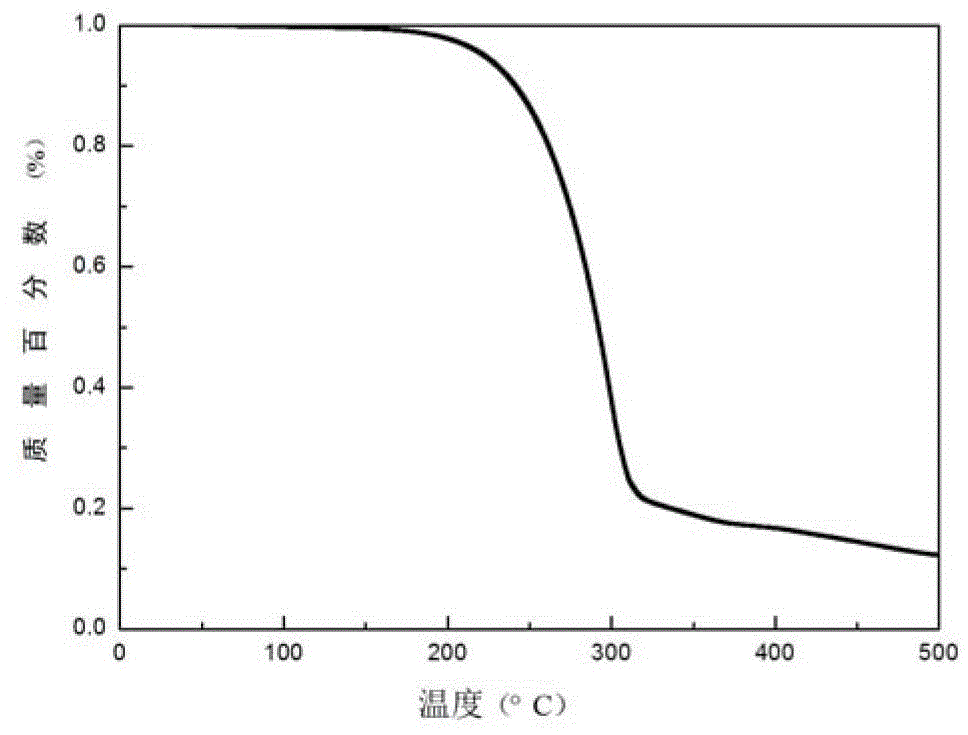

[0038] Mesoporous metal-organic framework Cr 3 F(H 2 O) 3 O(BTC) 2 ·nH 2 O in situ composite preparation of graphene-coated mesoporous metal-organic framework materials, selected mesoporous metal-organic framework Cr 3 F(H 2 O) 3 O(BTC) 2 ·nH 2 The specific surface area of O is 2700m 2 / g, the mesopore structure of the material accounts for 40% of the entire pore structure. Graphene oxide (GO) was mixed with water at a ratio of 2 mg / mL, and oscillated by ultrasonic waves for 0.5 h until a homogeneous solution was formed, and the prepared The mesoporous metal-organic framework material was added to the solution and stirred for 0.5h to form a precursor solution, and a mixed solution of hydrazine hydrate with a mass concentration of 80% and ammonia water with a mass concentration of 25% was added dropwise to the precursor solution at a volume ratio of 1:200 , wherein the mixing mass ratio of hydrazine hydrate and ammonia water is 9:1, and heated to reflux at 70°C for ...

Embodiment 2

[0042] Mesoporous metal-organic framework Cu 3 (TATAB) 2 (H 2 O) 3 ·8DMF·9H 2 O in situ composite preparation of graphene-coated mesoporous metal-organic framework materials, selected mesoporous metal-organic framework Cr 3 F(H 2 O) 2 O(BDC) 3 ·nH 2 The specific surface area of O is 1600m 2 / g, the mesopore structure of the material accounts for 35% of the entire pore structure. Graphene oxide (GO) was mixed with water at a ratio of 0.5 mg / mL, and oscillated by ultrasonic waves for 1 h until a homogeneous solution was formed, and the prepared The mesoporous metal-organic framework material was added to the solution and stirred for 1 h to form a precursor solution. A mixed solution of hydrazine hydrate with a mass concentration of 80% and ammonia water with a mass concentration of 20% was added dropwise to the precursor solution at a volume ratio of 1:50. Among them, the mixing mass ratio of hydrazine hydrate and ammonia water is 8:2, heated and refluxed at 100°C fo...

Embodiment 3

[0044] Mesoporous metal-organic framework Cr 3 F(H 2 O) 3 O(BTC) 2 ·nH 2 O in situ composite preparation of graphene-coated mesoporous metal-organic framework materials, selected mesoporous metal-organic framework Cr 3 F(H 2 O) 3 O(BTC) 2 ·nH 2 The specific surface area of O is 2700m 2 / g, the mesopore structure of the material accounts for 40% of the entire pore structure. Graphene oxide (GO) was mixed with water at a ratio of 2 mg / mL, and oscillated by ultrasonic waves for 0.5 h until a homogeneous solution was formed, and the prepared The mesoporous metal-organic framework material was added to the solution and stirred for 2 hours to form a precursor solution. A mixed solution of hydrazine hydrate with a mass concentration of 60% and ammonia water with a mass concentration of 28% was added dropwise to the precursor solution at a volume ratio of 1:100. The mixing mass ratio of hydrazine hydrate and ammonia water is 1:9, and heated to reflux at 80°C for 12 hours to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com