Light emitting diode epitaxial wafer and manufacturing method thereof

A technology of light-emitting diodes and epitaxial wafers, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as quantum well band bending, lattice mismatch, etc., to reduce defect density, improve buffering and interception capabilities, and improve potential The effect of base height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

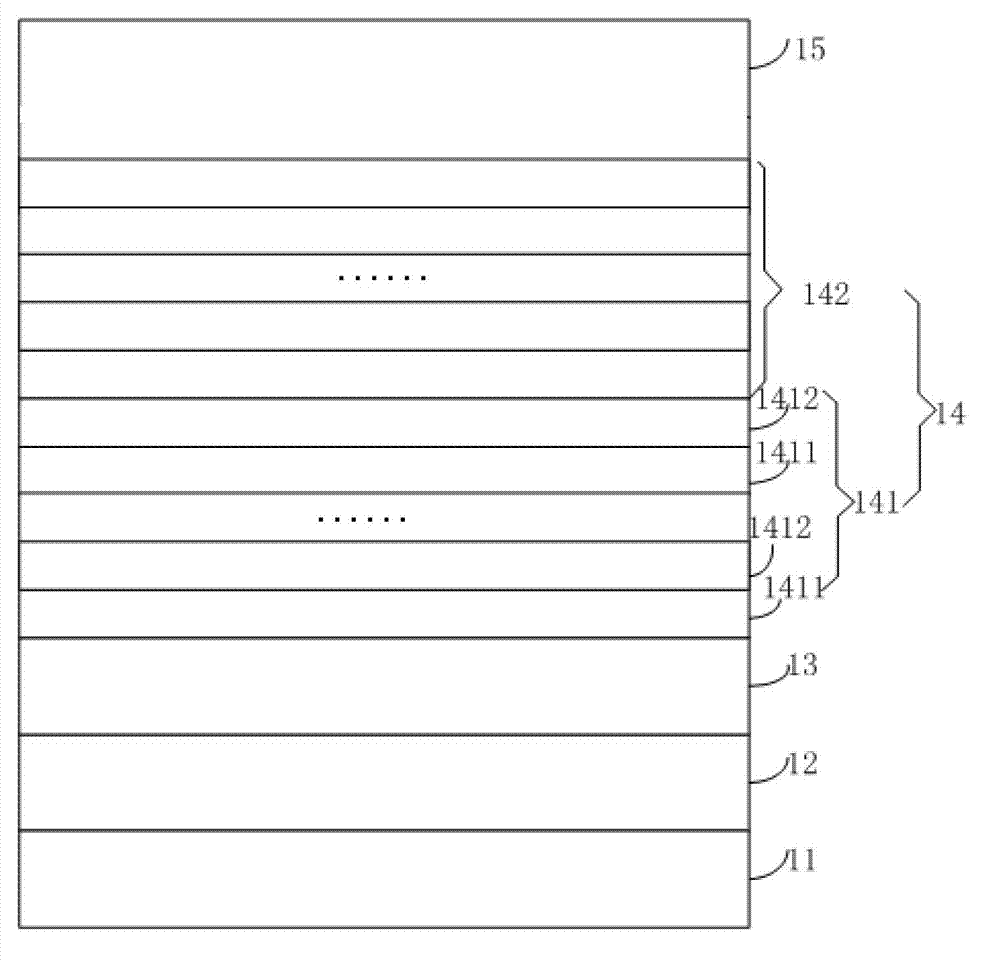

[0029] An embodiment of the present invention provides an epitaxial wafer of a light emitting diode, see figure 1 , the epitaxial wafer includes:

[0030] The substrate 11 and the buffer layer 12, n-type layer 13, multi-quantum well layer 14 and p-type layer 15 stacked in sequence on the substrate 11, the p-type layer 15 is directly arranged on the multi-quantum well layer 14, and the multi-quantum well layer 14 includes a first multi-quantum well layer 141 and a second multi-quantum well layer 142, and the first multi-quantum well layer 141 is composed of several In a Ga 1-a N quantum well layer 1411 and several quantum barrier layers 1412 are stacked alternately, and at least one of the several quantum barrier layers 1412 in the first multi-quantum well layer 141 is Al x In y Ga 1-x-y N layer, wherein, 0b Ga 1-b N quantum well layers and several quantum barrier layers are stacked alternately, and a≤b.

[0031] In a specific implementation, since the higher the temperat...

Embodiment 2

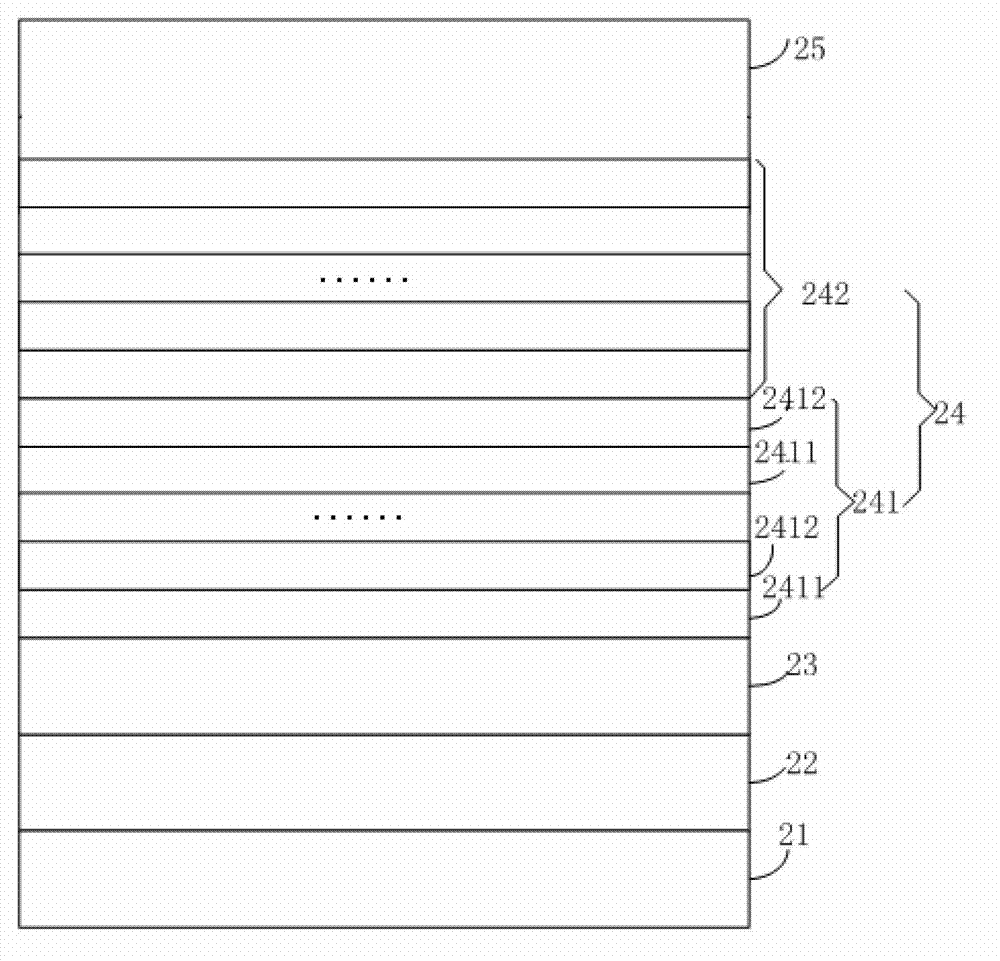

[0034] An embodiment of the present invention provides an epitaxial wafer of a light emitting diode, see figure 2 , the epitaxial wafer includes:

[0035]Substrate 21 and the buffer layer 22, n-type layer 23, multi-quantum well layer 24 and p-type layer 25 stacked in sequence on the substrate 21, the p-type layer 25 is directly arranged on the multi-quantum well layer 24, the multi-quantum well layer 24 includes a first multi-quantum well layer 241 and a second multi-quantum well layer 242, the growth temperature of the first multi-quantum well layer 241 is higher than the growth temperature of the second multi-quantum well layer 242, and the first multi-quantum well layer 141 is composed of several In a Ga 1-a N quantum well layer 2411 and several quantum barrier layers 2412 are stacked alternately, and at least one of the several quantum barrier layers 2412 in the first multi-quantum well layer 241 is Al x In y Ga 1-x-y N layer, wherein, 0b Ga 1-b N quantum well layer...

Embodiment 3

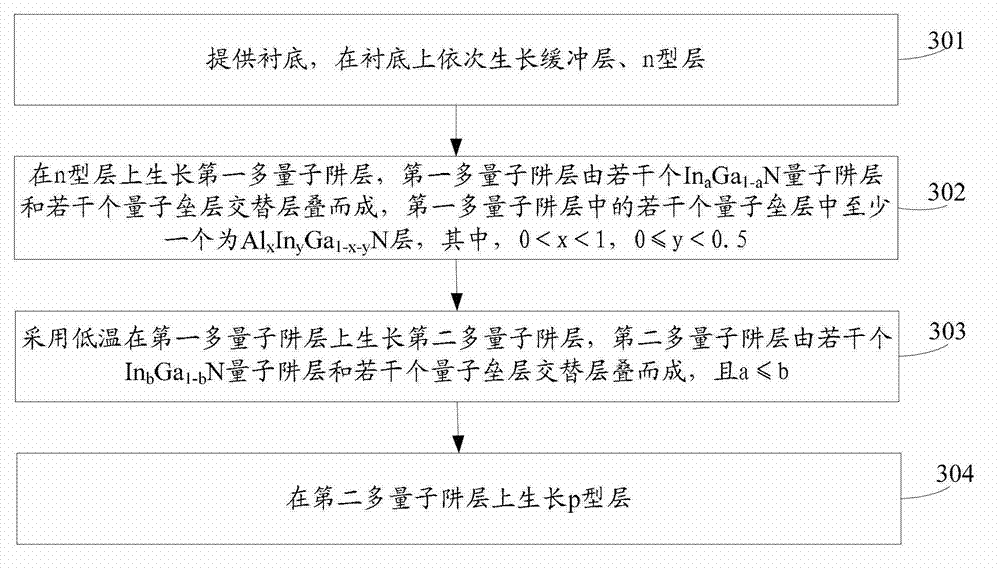

[0051] An embodiment of the present invention provides a method for manufacturing an epitaxial wafer of a light emitting diode, see image 3 , the method includes:

[0052] Step 301: providing a substrate, and sequentially growing a buffer layer and an n-type layer on the substrate.

[0053] Step 302: growing a first multi-quantum well layer on the n-type layer, the first multi-quantum well layer is composed of several In a Ga 1-a N quantum well layers and several quantum barrier layers are stacked alternately, and at least one of the several quantum barrier layers in the first multi-quantum well layer is Al x In y Ga 1-x-y N layers, where 0

[0054] Step 303: Using low temperature to grow a second multi-quantum well layer on the first multi-quantum well layer, the second multi-quantum well layer is composed of several In b Ga 1-b N quantum well layers and several quantum barrier layers are stacked alternately, and a≤b.

[0055] In a specific implementati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com