Filling method of groove

A filling method and trench filling technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve the effect of matching stress

Active Publication Date: 2013-04-10

SHANGHAI HUAHONG GRACE SEMICON MFG CORP

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

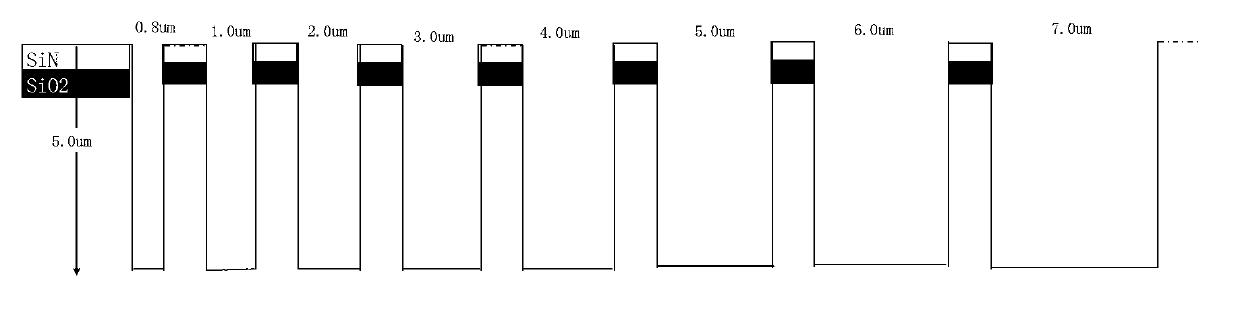

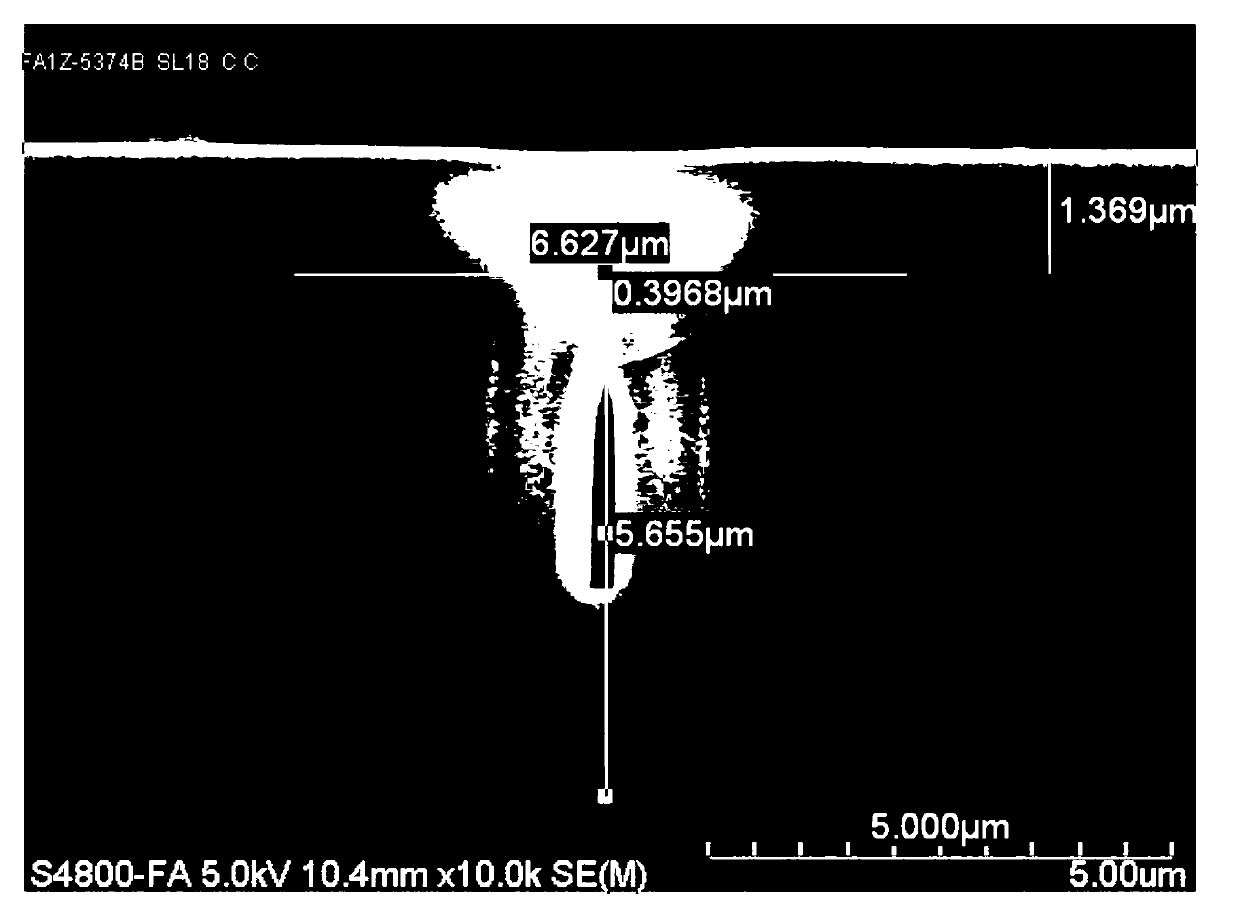

However, when the structure of the trench is several microns in depth and the opening size is from 0.8 to 7 microns at the same time, the filling of the trench becomes quite challenging.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Opening width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a filling method of a groove. The filling method of the groove is finished by filling the groove in the manufacturing process of a semiconductor device, wherein a first monox thin film and a second monox thin film are circularly deposited and etched back in the groove. Stress of the first monox thin film is opposite to the stress of the second monox thin film. The two monox thin films with opposite stresses resolve the matching problem of stresses among different monox thin films. Filling requirements of large openings and deep grooves are simultaneously met.

Description

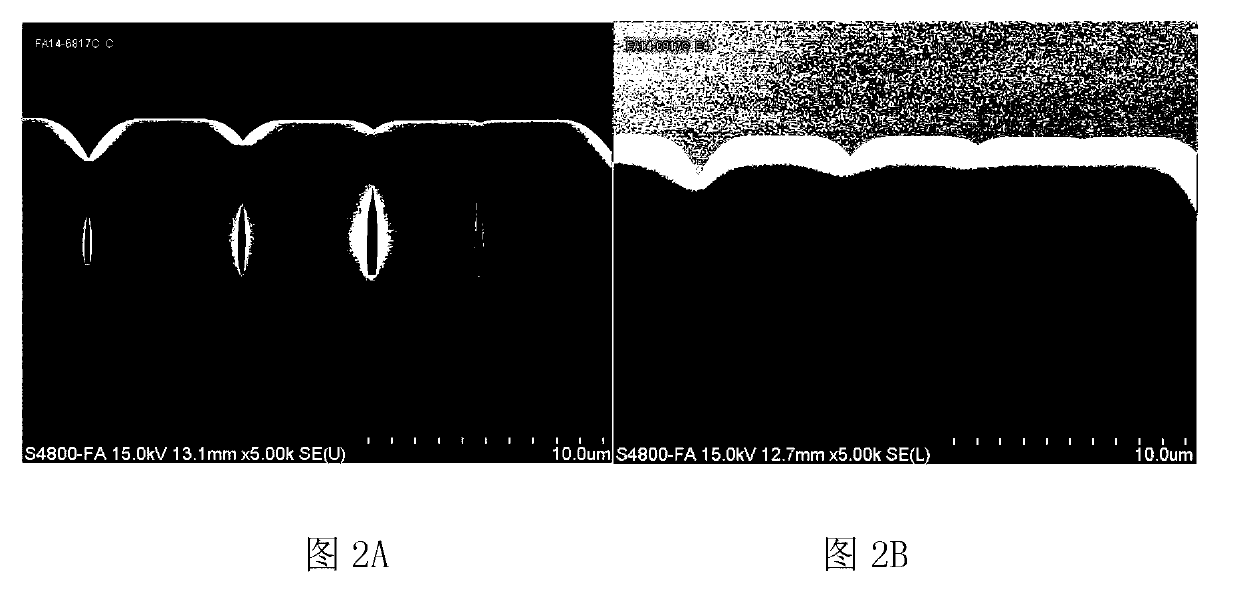

technical field The invention relates to the field of semiconductor device manufacturing, in particular to a trench filling method. Background technique The filling of trenches is a particularly critical step in semiconductor fabrication. At present, silicon dioxide and its derivatives are widely used for trench filling due to their good film properties. The traditional preparation process includes spin coating (Spin on Glass), sub-atmospheric pressure chemical vapor deposition (SACVD: Sub Atmosphere Chemical Vapor Deposition), plasma chemical vapor deposition (PECVD: Plasma Enhanced Chemical Vapor Deposition) and high-density plasma chemical Vapor deposition method (HDPCVD: High Density Plasma Chemical Vapor Deposition) and the like. The usual trench structure has a depth of no more than 1 micron and an opening of less than 0.25 micron (the size of the opening is fixed). Such a structure can be filled with no holes (Void free) by a simple single-step chemical vapor deposi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01L21/316H01L21/311

Inventor 成鑫华罗啸钱志刚袁苑

Owner SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com