Cement on-line simulation system and implementation method thereof

A simulation system and cement technology, applied in the field of cement online simulation system, can solve the problems of complex operation and numerous equipment, and achieve the effect of improving analysis ability

- Summary

- Abstract

- Description

- Claims

- Application Information

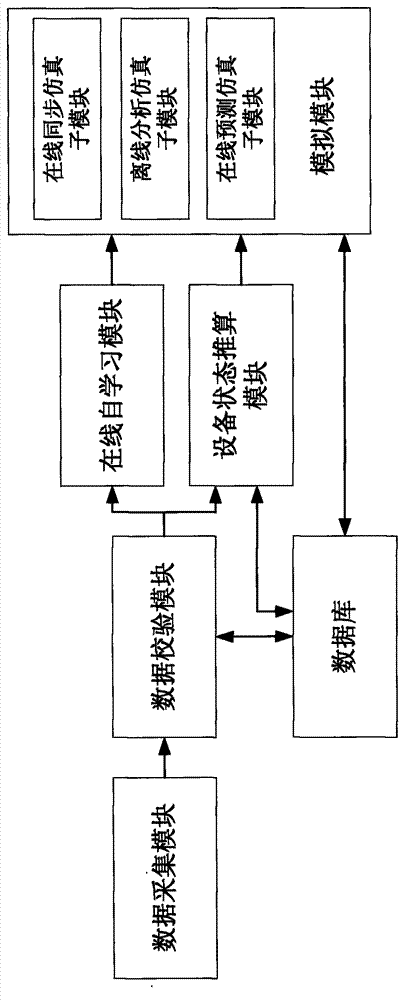

AI Technical Summary

Problems solved by technology

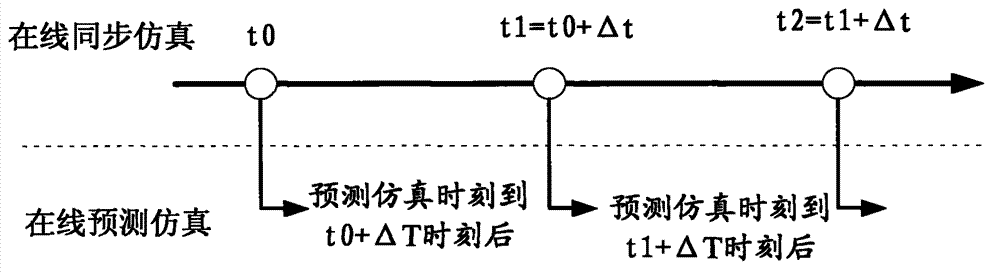

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

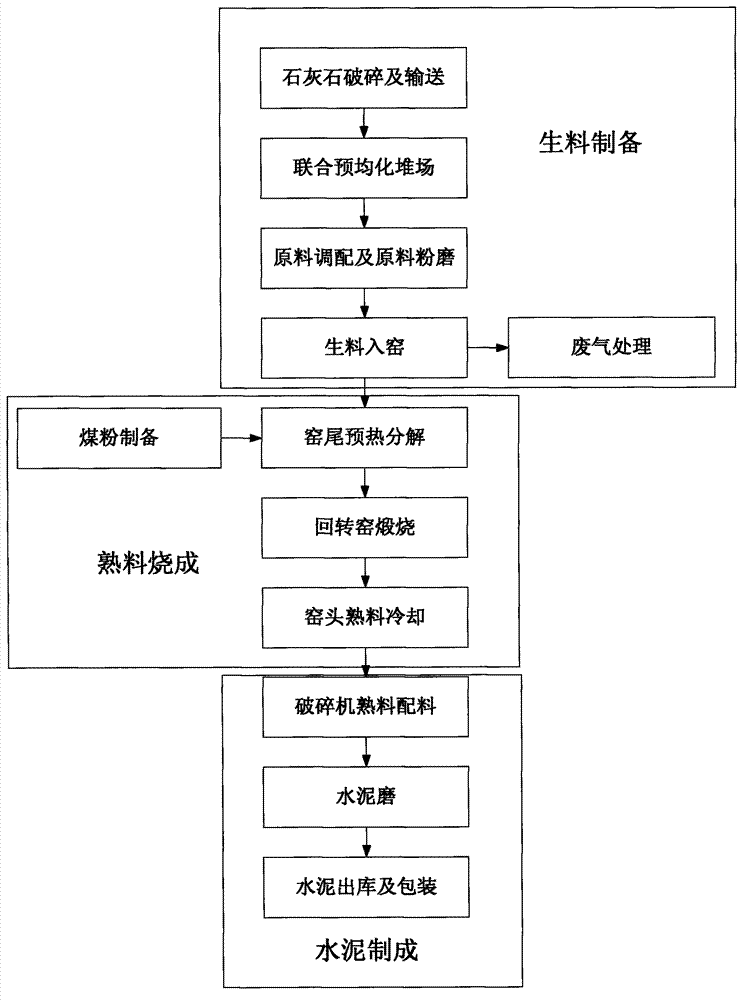

[0039] The cement online simulation system can include the simulation of raw meal preparation, clinker firing, cement production and other systems. Taking the 5000t / d clinker dry process production line as an example, it can specifically include:

[0040] 1. Raw material preparation system

[0041] (1) Limestone crushing and conveying system

[0042] Simulation scope: heavy-duty apron feeder, single-stage hammer crusher, dust collector, exhaust fan, centrifugal fan, motor, dust collector gas storage tank, belt conveyor, pulse single machine with dust collector, round yard stack Reclaimer etc.

[0043] (2) Combined pre-homogenization yard system

[0044] Simulation scope: coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com