Building plaster mold box and open-web floor slab structure using same

A technology of building gypsum and hollow floor slabs, which is applied to building components, building structures, and floor slabs. It can solve the problems of large-scale production of specifications, high labor costs, and high costs. The effect of optimal stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Combine below Figure 1 to Figure 3 , the present invention is further described:

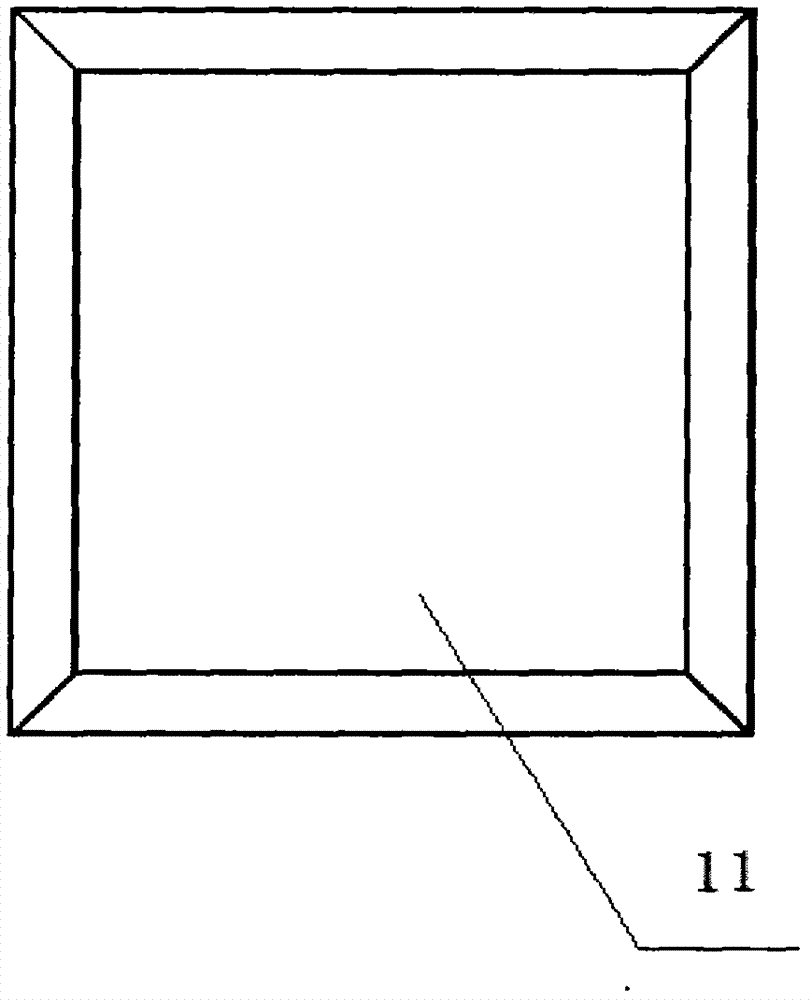

[0029] like figure 1 As shown, a building gypsum mold box includes a mold box body, and a step 11 is formed outside the mold box body.

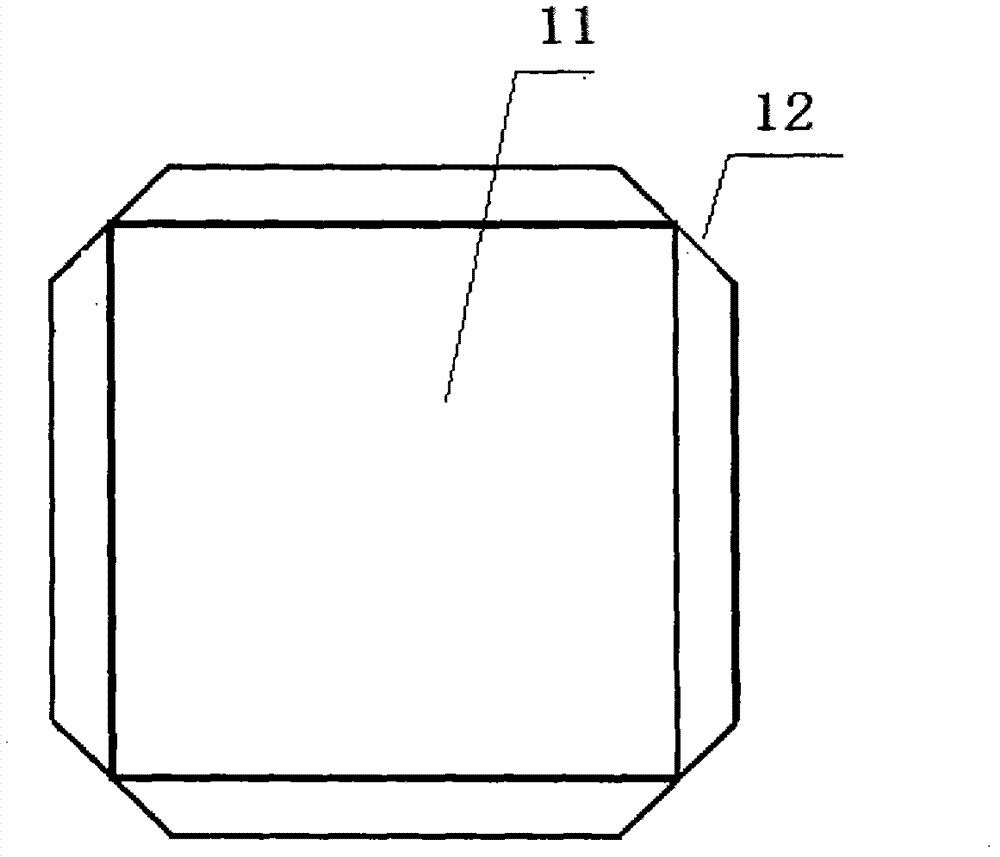

[0030] like figure 2 As shown, a kind of building gypsum mold box mold box body is a quadrilateral, and cut corners 12 at the four corners of the quadrilateral.

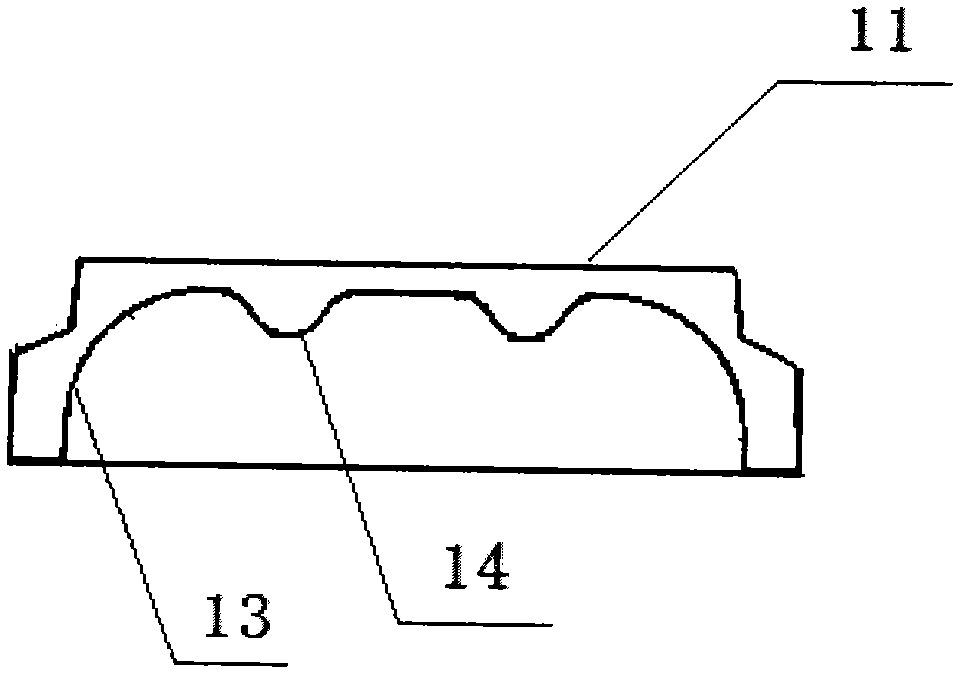

[0031] like image 3 As shown, the inside of the mold box body is a hollow mold cavity 13, and the bottom of the hollow mold cavity 13 is provided with reinforcing ribs 14.

[0032] From a technical point of view, the building floor is a typical flexural structural member, and its bearing capacity is proportional to the square of its section height. The building floor is a bending-resistant member, and its bearing capacity is proportional to the square of its section height. The traditional floor is Solid slabs have the largest amount of materials, but the bearing capacity is not high. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com