Light high-crack-resistance cement concrete

A cement concrete, high crack resistance technology, applied in the field of building materials, can solve the problems of high density, increase the investment cost of infrastructure, etc., achieve the effect of reducing density, improving anti-seismic effect, and strong technical advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

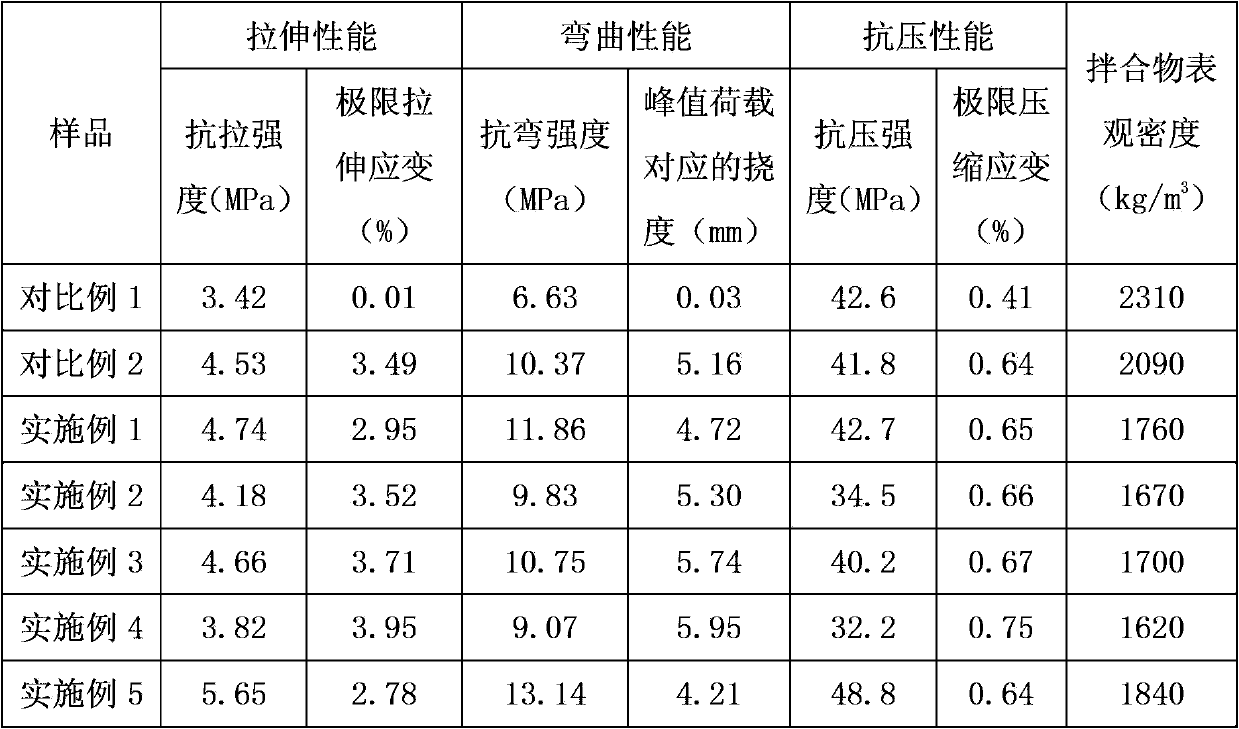

Examples

Embodiment 1

[0040] Example 1: Lightweight and highly crack-resistant cement concrete

[0041] Lightweight high-cracking-resistant cement concrete, based on 100 parts by weight, consists of the following raw materials: 40 parts of cementitious material, 14 parts of rubber particles, the particle size is 60 mesh, 0.14 parts of silane coupling agent, 29.06 parts of river sand, water 15.2 parts, 0.2 parts of water reducer, 1.4 parts of polymer fibers, of which:

[0042] The weight ratio of cement, fly ash, silica fume and fine limestone powder in the cementitious material is 75:16:5:4;

[0043] The weight ratio of polyvinyl alcohol fiber and polypropylene fiber in the polymer fiber is 80:20.

[0044] The above-mentioned raw materials are prepared into light-weight high-crack-resistant cement concrete according to the following steps.

[0045] (1) Weigh the cementitious material, rubber particles, silane coupling agent, river sand, water, water reducing agent and polymer fiber according to t...

Embodiment 2

[0048] Example 2: Lightweight and highly crack-resistant cement concrete

[0049] The difference between this embodiment and the above embodiment is only that the ratio of raw materials is different. Based on 100 parts by weight, it is composed of the following raw materials: 35 parts of gelling material, 18 parts of rubber particles, and the particle size is 60 mesh; silane coupling agent 0.27 32.33 parts of river sand; 12.6 parts of water; 0.20 parts of water reducing agent; 1.6 parts of polymer fiber, of which:

[0050] The weight ratio of cement, fly ash, silica fume and fine limestone powder in the cementitious material is 80:10:6:4;

[0051] The weight ratio of polyvinyl alcohol fiber and polypropylene fiber in the polymer fiber is 70:30.

Embodiment 3

[0052] Example 3: Lightweight and highly crack-resistant cement concrete

[0053] The difference between this embodiment and the above embodiment is only the ratio of raw materials, which is composed of the following raw materials in terms of 100 parts by weight: 38 parts of gelling material, 17 parts of rubber particles, the particle size is 80 mesh, and the silane coupling agent is 0.21 27.79 parts of river sand, 15 parts of water, 0.20 parts of water reducer, 1.8 parts of polymer fiber, of which:

[0054] The weight ratio of cement, fly ash, silica fume and fine limestone powder in the cementitious material is 72:15:10:3;

[0055] The weight ratio of polyvinyl alcohol fiber and polypropylene fiber in the polymer fiber is 75:25.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com