Cement production and optimization system

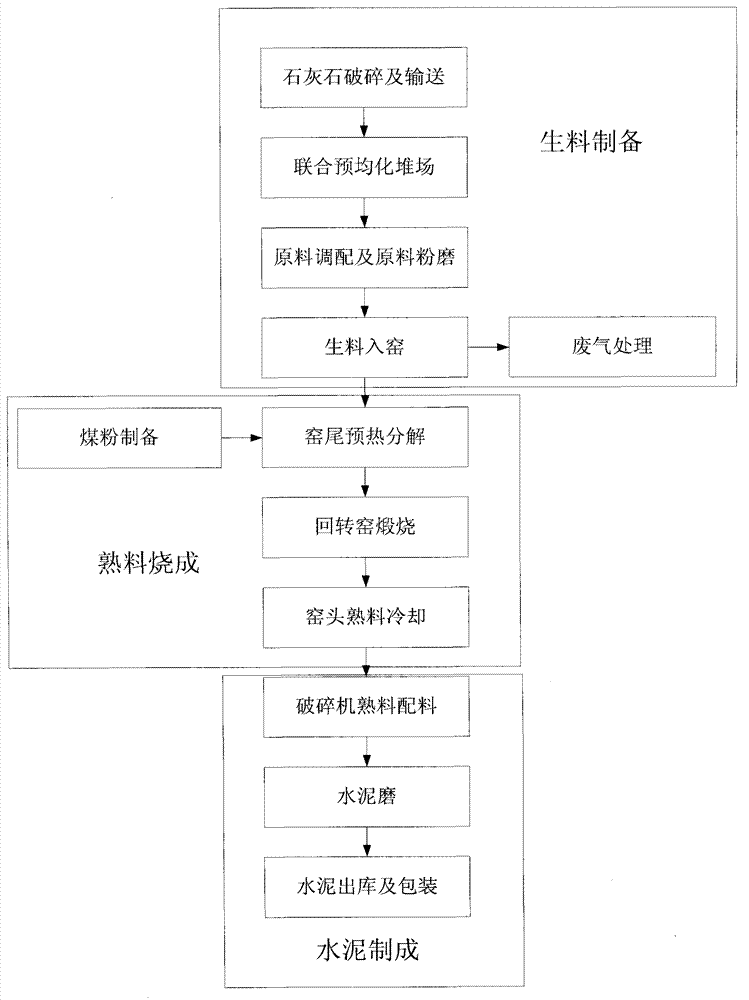

A cement and system optimization technology, applied in cement production, clinker production, etc., can solve problems such as numerous equipment, complex operation, and large system, and achieve the effect of improving safety and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

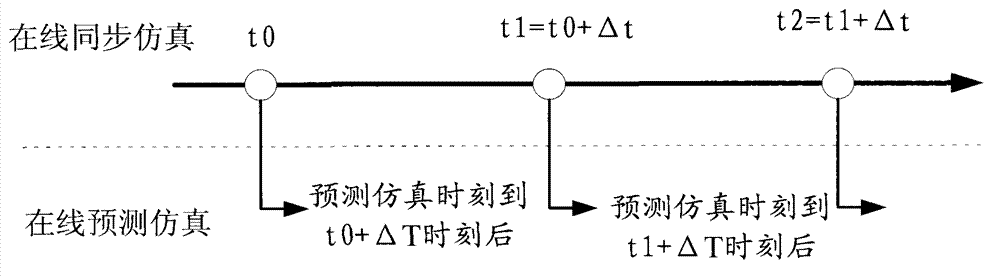

[0048] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

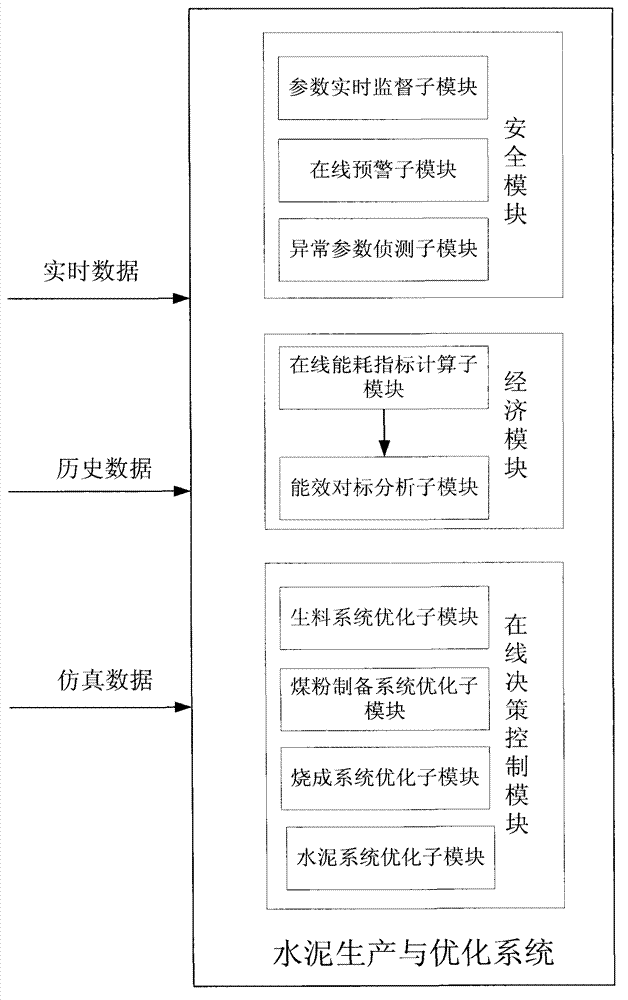

[0049] like figure 2 As shown, the cement production and optimization system of the embodiment of the present invention includes a security module, an economic module and an online decision-making control module, wherein,

[0050] The safety module is used for analyzing and judging whether the current operation parameters and the operation of the cement production equipment are normal according to the real-time data, historical data and simulation data of the cement production equipment, and predicting whether the operation parameters after the current moment are normal;

[0051] The economic module is used to calculate the comprehensive energy consumption and distributed ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com