Paraffin leveling and recycling device

A recovery device and paraffin wax technology, applied in the direction of coating, etc., can solve the problems of low processing efficiency, leveling effect difficult to meet the processing technology, etc., to improve production efficiency, realize leveling and recycling work, and increase the degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

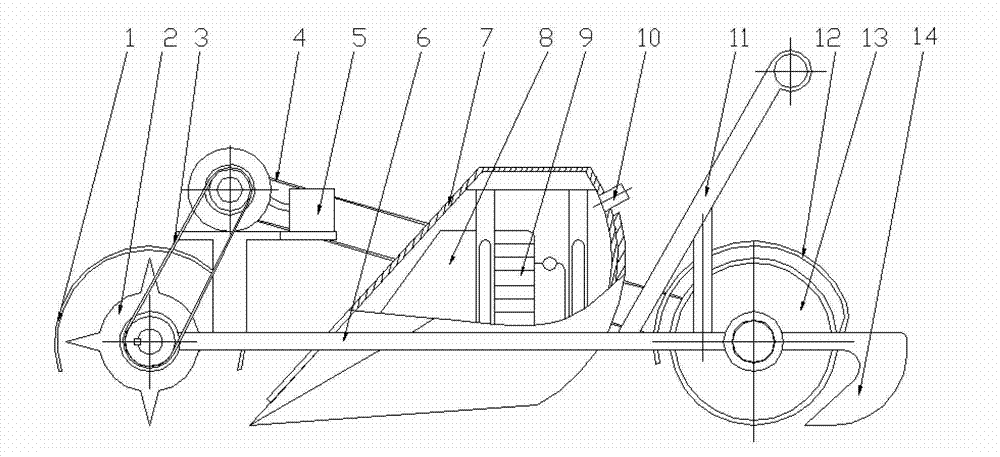

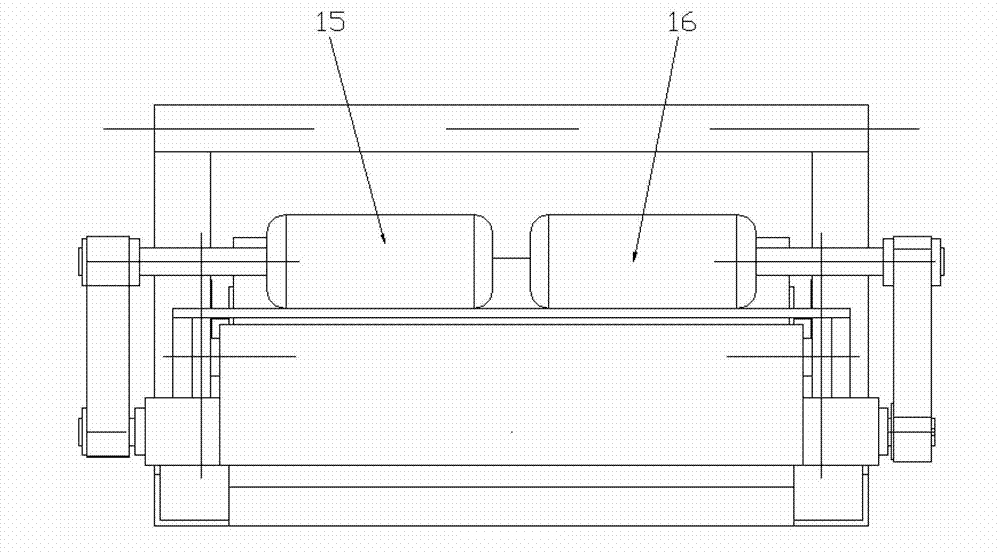

[0015] Paraffin leveling and recovery device of the present invention such as figure 1 and figure 2 As shown, it mainly includes a frame 6, a leveling star wheel 2, a wax recovery device 7, a heating drum 13 and a wax cleaning shovel 14. The frame 6 is provided with a leveling star wheel 2 , a wax suction recoverer 7 and a heating roller 13 sequentially from front to back. The rear portion of the frame 6 is provided with a handle 11, and the whole device can be moved by pushing the handle 11. The leveling star wheel 2 is installed on the front end of the frame 6 through a rotating shaft, and a plurality of blades are evenly arranged on the leveling star wheel 2 . The leveling star wheel 2 is connected with the star wheel transmission mechanism installed on the frame, and the star wheel transmission mechanism is a belt drive or a chain drive, including a star wheel motor 16 and a star wheel drive belt 3 (see figure 2 ), star wheel transmission belt 3 also can adopt chain d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com