High-frequency mould-pressing hot press machine

A hot press and molding technology, applied in the direction of wood compression, etc., can solve the problems of long heat curing cycle, low work efficiency, low production efficiency, etc., and achieve the effect of obvious heating effect, precise control and fast forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

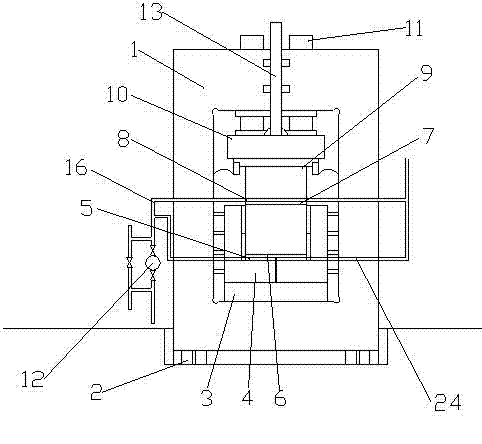

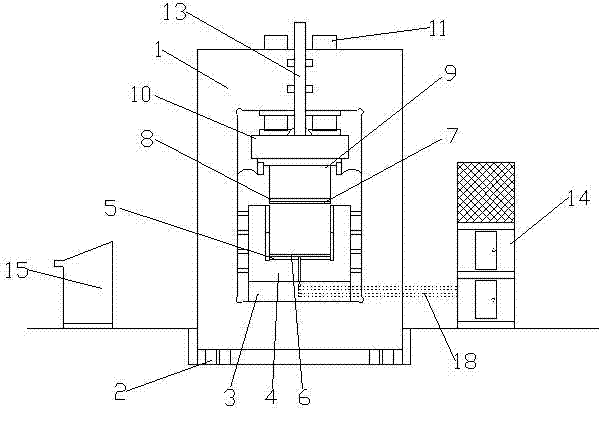

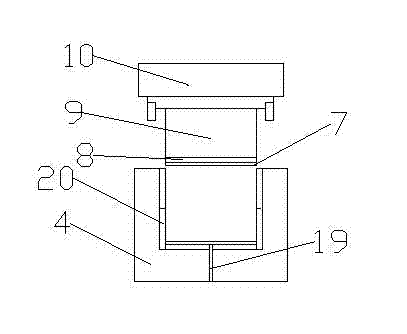

[0025] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, and 13, a high-frequency molding hot press includes a frame 1 arranged on the bottom beam 2, and a frame 1 bottom The fixed beam 3, the hot press plate 5 arranged on the fixed beam 3, the upper die head 8 arranged on the hot press plate 5, the pressure oil cylinder 9 connected with the upper die head 8, communicate with the pressure oil cylinder 9 The hydraulic rod 11, the lifting block 10 arranged above the pressure cylinder 9, the guide rod 13 connected with the lifting block 10, and the electrical control system 15 arranged on one side of the frame 1, the frame 1 side is provided with the upper The steam heating system 12 connected with the die head 8 and the hot pressing plate 5, the mold 4 is set above the fixed beam 3, the hot pressing plate 5 is arranged on the bottom surface of the mold 4, and the lower electrode deflector 6 is arranged above the hot pressing plate 5 , the upper electrode deflector 7 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com