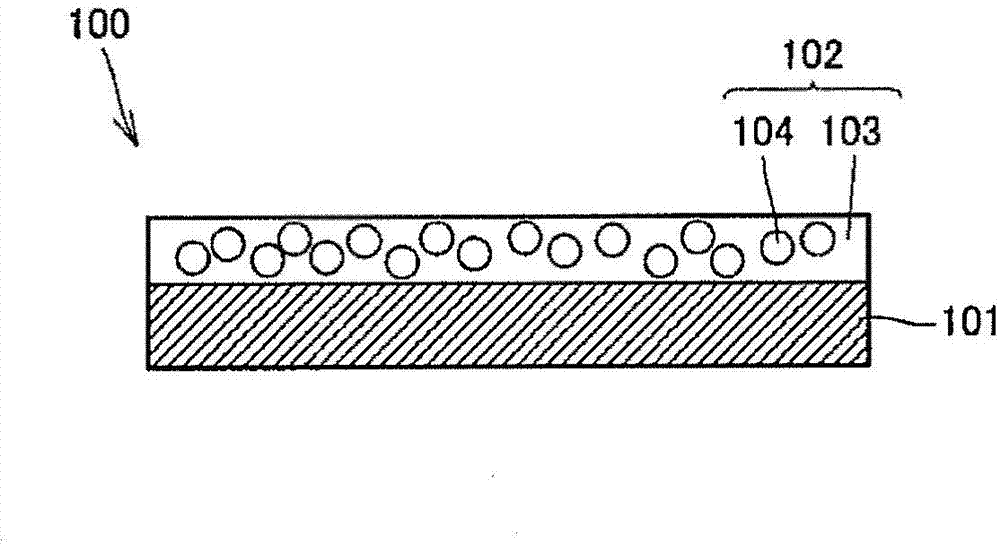

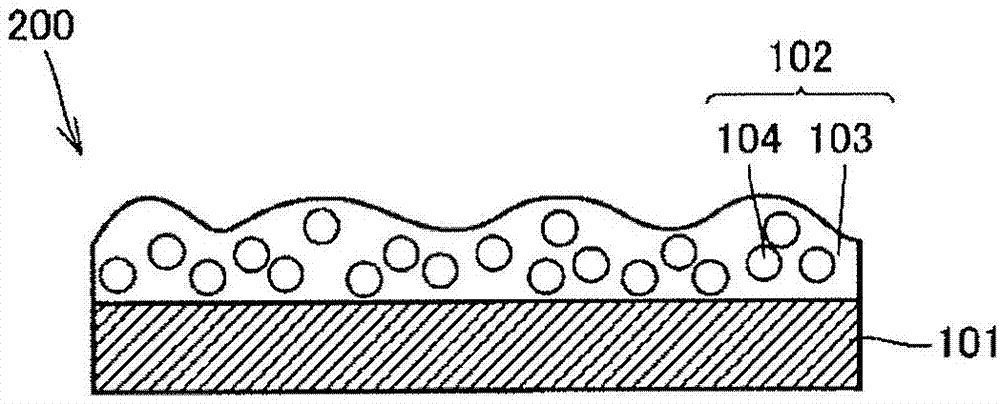

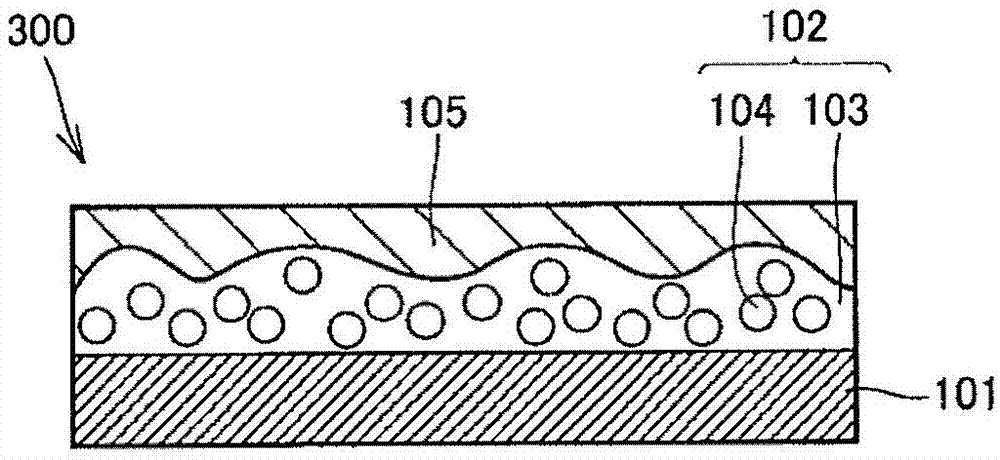

Light-scattering film, method of manufacturing same, light-scattering polarizing plate, and liquid-crystal display device

A technology of liquid crystal display device and light diffusion film, which is applied in the direction of polarizing elements, lighting devices, chemical instruments and methods, etc., to achieve the effect of good front brightness and high dot concealment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0200] (1) Production of mirror metal rollers

[0201] The surface of an iron roll (STKM13A specified by JIS) with a diameter of 200 mm was subjected to industrial chrome plating, and then the surface was mirror-polished to produce a mirror-finished metal roll. The Vickers hardness of the chrome-plated surface of the obtained mirror-finished metal roller was 1,000. In addition, Vickers hardness was measured based on JISZ2244 using the ultrasonic hardness meter MIC10 (made by Krautkramer).

[0202] (2) Production of light diffusion film

[0203] Mix 60 parts by weight of pentaerythritol triacrylate and 40 parts by weight of polyfunctional urethanized acrylate (reaction product of 1,6-hexamethylene diisocyanate and pentaerythritol triacrylate) in the propylene glycol monomethyl ether solution to adjust the solid content concentration 60% by weight to obtain an ultraviolet curable resin composition. Moreover, the refractive index of the hardened|cured material which removed pr...

Embodiment 2~6

[0207] A light-diffusing film was produced in the same manner as in Example 1 except that the thickness of the light-diffusing layer and the weight-average particle diameter of the translucent fine particles, the standard deviation of the particle diameter, and the addition amount were as described in Table 1.

Embodiment 7

[0209] (1) Production of metal rolls for embossing

[0210] A roll having a diameter of 200 mm of an iron roll (STKM13A specified by JIS) on the surface of which Ballard copper plating was provided was prepared. Ballard copper plating consists of copper plating / thin silver plating / surface copper plating, the thickness of the entire plating is about 200μm. Mirror-polish the surface of the copper coating, and then use a sandblasting device (manufactured by Fuji Manufacturing Co., Ltd.), with a sandblasting pressure of 0.05MPa (gauge pressure, the same below), and a particle usage of 16g / cm 2 (per 1cm of roll 2 The amount of surface area used, the same below) was used to form irregularities on the surface of the polished surface blasted zirconia beads TZ-B125 (manufactured by Tosoh Corporation, average particle diameter: 125 μm). Use a sandblasting device (manufactured by Fuji Manufacturing Co., Ltd.), with a blasting pressure of 0.1MPa and an amount of fine particles of 4g / cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com