Chip LED and manufacturing method thereof

A CHIP-LED and manufacturing method technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of conductive vias overflowing glue, affecting product quality, etc., to reduce surface tension, improve welding performance, and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

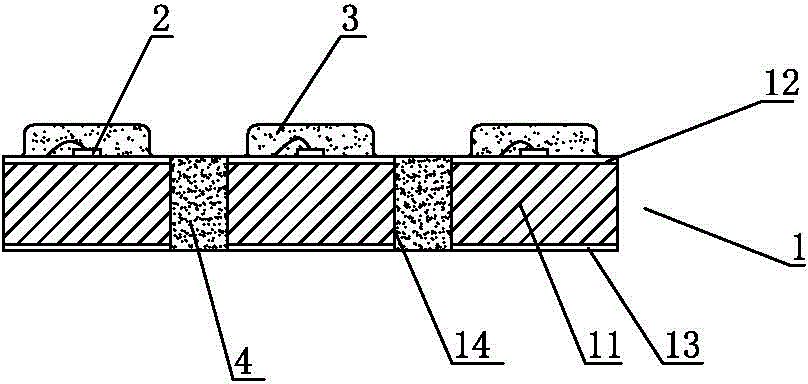

[0018] Such as figure 1 As shown, the CHIP-LED includes a substrate 1 and an LED chip 2. The substrate 1 includes a body 11, a front circuit layer 12 arranged on the upper surface of the body, a back circuit layer 13 arranged on the lower surface of the body, and a circuit layer 13 arranged on the body. The conductive via hole 14 on the top and the connection circuit layer arranged on the inner wall of the conductive via hole for electrically connecting the front circuit layer and the back circuit layer; the LED chip 2 is installed on the front circuit layer through the solid crystal bonding process; The via holes are filled with rosin 5 .

[0019] The method of manufacturing the above-mentioned CHIP-LED is as follows.

[0020] (1) Fabricate the substrate 1 .

[0021] (2) Install a backing plate on the lower surface of the substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com