Stripping agent containing alkylamide mixture

A technology of alkyl amide and stripper, applied in the field of alkyl amide stripper, can solve problems such as difficult recycling, high evaporation rate, loss and cost reduction, etc., achieve environmental protection, simple composition, and reduce production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

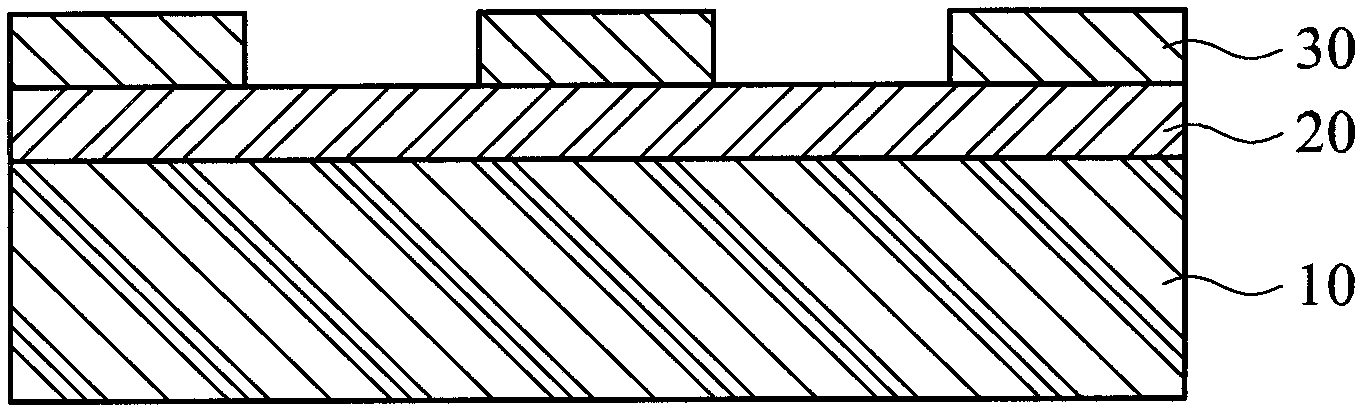

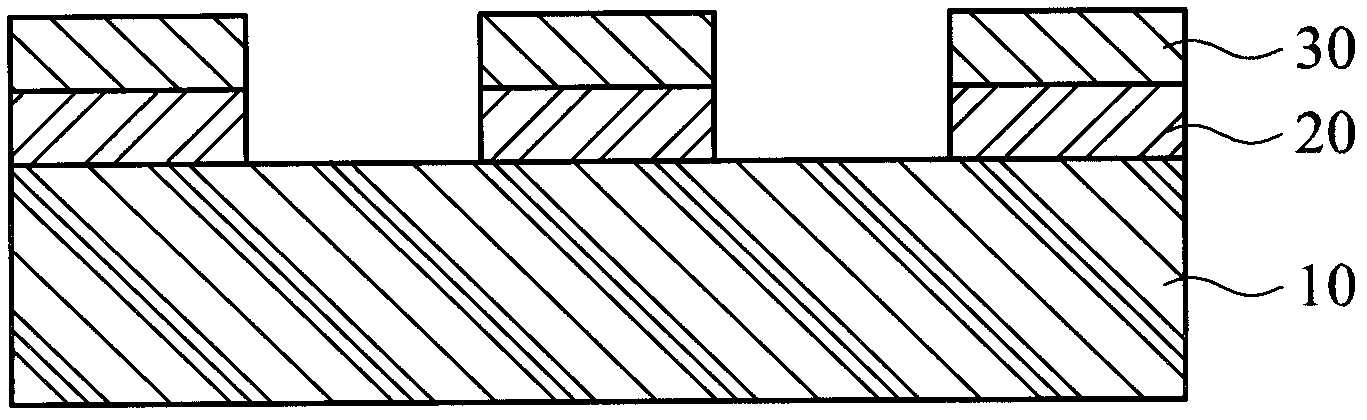

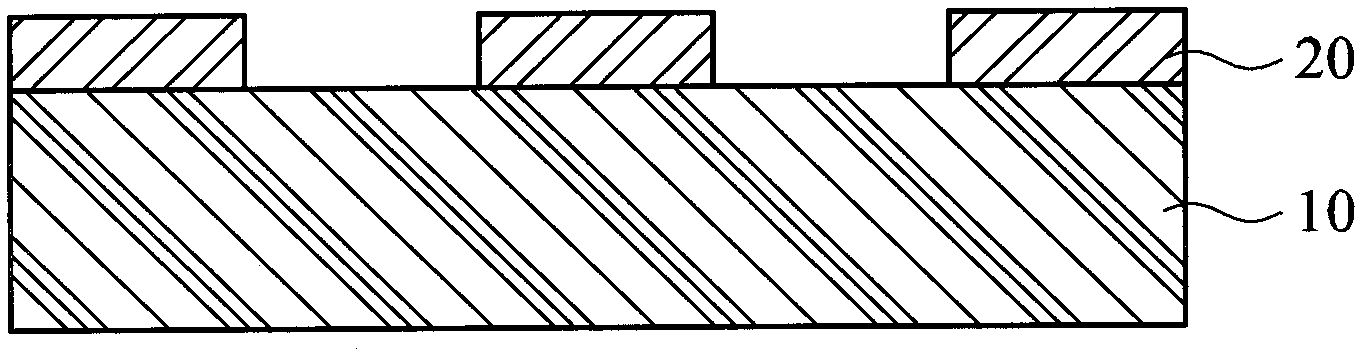

Image

Examples

Embodiment

[0049] A. Peeling and corrosion test of copper foil:

[0050] Cut a piece of copper foil of an appropriate size (about 6cmx26cm, about 2.2g), and use a microetch to clean the surface of the copper foil to remove oxides on the surface. After washing with deionized water and drying, the weight of the copper foil (initial weight) was accurately measured. Put the copper foil into a beaker containing 400g of stripping agent (see Table 1 for components), test the corrosion resistance to copper, heat it at 80°C for 8 hours, wash it with deionized water and dry it, and measure it accurately Post-test weight of copper foil. Calculate the weight reduction of copper foil and calculate its corrosion rate (see Table 2).

[0051] Table I

[0052]

formula

Comparative example 1

100% DMAC

Comparative example 2

100% NMF

Comparative example 3

DMAC(60%)+NMF(40%)

Comparative example 4

DMAC(59%)+NMF(40%)+tetraethylene glycol(1%)

Exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com