Nano-zinc oxide modified immunocapillary and its preparation method and application

A nano-zinc oxide and capillary technology, applied in the direction of measuring devices, instruments, fluorescence/phosphorescence, etc., can solve the problems of low sensitivity of immune devices, poor signal uniformity, and difficult application of immune analysis, etc., to achieve sensitive immune analysis and improve the surface Density, the effect of convenient optical detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

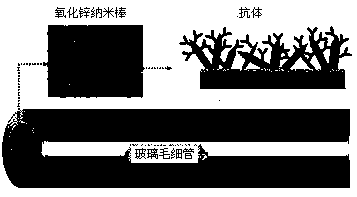

[0034] The preparation method of the immune capillary modified by nano-zinc oxide, the specific steps are as follows:

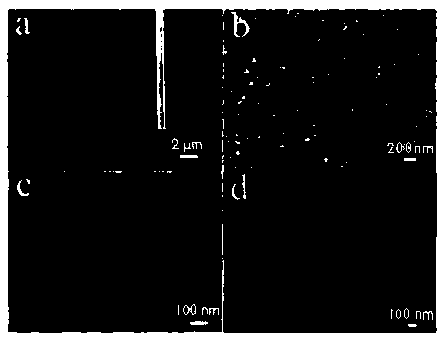

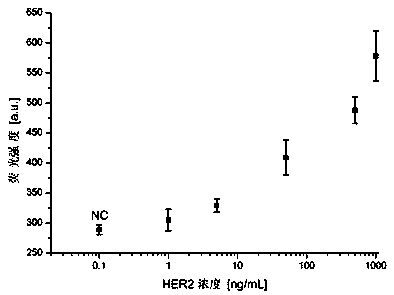

[0035] (1) Take a newly prepared potassium permanganate solution with a concentration of 5mM and inject it into the glass capillary, soak it for 20 minutes to activate the glass capillary; then rinse it with deionized water, and then put it into the glass capillary containing 5% (v / v) ethanolamine and 5% (v / v) In the 50mM zinc nitrate solution of ammoniacal liquor, grow in 80 ℃ of water baths for 50 minutes, form zinc oxide nanorod on capillary surface, the tube wall of capillary is photographed with scanning electron microscope, its result is as follows figure 1 shown.

[0036] (2) Rinse the glass capillary treated in step (1) with deionized water, then inject 3% (v / v) ethanol solution of 3-epoxypropyloxypropyltrimethoxysilane after drying, soak for 2 Hours, 3-epoxypropyloxypropyltrimethoxysilane and ZnO nanostructures and capillary inner walls formed sili...

Embodiment 2

[0040] The preparation method of the immune capillary modified by nano-zinc oxide, the specific steps are as follows:

[0041] (1) Take a newly prepared potassium permanganate solution with a concentration of 1mM and inject it into the glass capillary, soak for 30 minutes to activate the glass capillary; then rinse with deionized water, put 1% (v / v) ethanolamine and 1% (v / v ) in a 10 mM zinc nitrate solution of ammonia water and grown in a water bath at 65° C. for 60 minutes to form zinc oxide nanorods on the surface of the capillary.

[0042](2) Rinse the glass capillary treated in step (1) with deionized water, then inject 1% (v / v) ethanol solution of 3-epoxypropyloxypropyltrimethoxysilane after drying, soak for 1 After 3-epoxypropyloxypropyltrimethoxysilane and the ZnO nanostructure and the inner wall of the capillary formed a silicon-oxygen covalent bond, rinsed with ethanol and annealed in vacuum at 110°C for 3 hours, then added 50 μg / mL mouse anti-human CEA (carcino-em...

Embodiment 3

[0046] The preparation method of the immune capillary modified by nano-zinc oxide, the specific steps are as follows:

[0047] (1) Prepare the colloidal solution of zinc oxide nanoparticles according to the prior art (for the preparation method see: ContinuousSizeTuningofMonodisperseZnOColloidalNanocrystalClustersbyaMicrowave-PolyolProcessandTheirApplicationforHumiditySensing, XianluoHu, JingmingGong, LizhiZhangandJimmyC.Yu.Adv.Mater.2008, 20, (24), 484 The solution is injected into the glass capillary, soaked for 20 minutes, and then the colloidal solution is discharged. The steps of soaking and discharging can be repeated several times to increase the adsorption capacity of zinc oxide nanoparticles, and then calcined at 150°C for 60 minutes. taken by electron microscope, the results are as follows Figure 5 shown.

[0048] (2) Inject the glass capillary treated in step (1) into 1% (v / v) ethanol solution of 3-epoxypropyloxypropyltrimethoxysilane, soak for 3 hours, and 3-epox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com