Dual-drive tunnel heading machine speed reducer

A technology of tunnel boring machine and reducer, which is applied in mechanical equipment, gear transmission, belt/chain/gear, etc., to achieve the effect of improving load sharing performance, convenient installation and maintenance, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

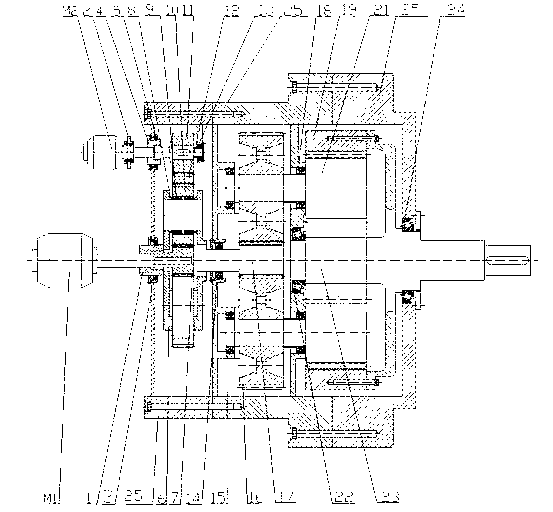

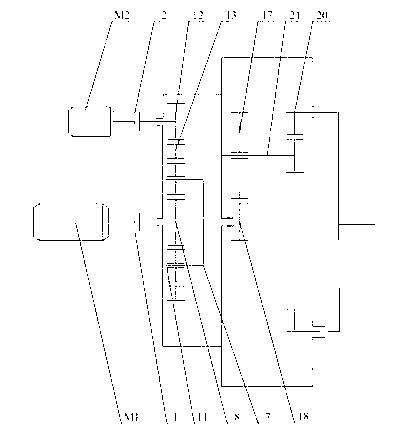

[0023] The brakes 2 are all in the closed state, the power input component IM1 transmits the power to the input sun gear 8, the sun gear drives the input planetary gear 10 meshed with it, the input planetary gear 10 undergoes self-propagation and revolution, and transmits the power to the planetary carrier 6, the planetary The frame 6 is used as the input of the second stage to drive the pinion shaft 17 to rotate, and the pinion shaft 17 is meshed with three large gears 16 evenly distributed on the circumference for transmission to realize shunting. The interference fit of the large gear 16 is connected to the output gear shaft 21 Circumferential transmission cooperation, the output gear shaft 21 and the ring gear 19 are meshed for transmission to realize confluence, the ring gear 19 and the power output shaft 23 are fixedly connected in the circumferential direction, thereby realizing power output, and the power output shafts of multiple speed reducers 26 The power is transmit...

Embodiment approach 2

[0025]Coupling Ⅰ1 and brake 2 are both in the disengaged state, power input component IM1 and power input component IIM2 rotate in the same direction, power input component IM1 transmits power to the input sun gear 7, and power input component IIM2 transmits power to the input external gear 11 And transmitted to the input ring gear 12, the rotation of the input sun gear 7 and the input ring gear 12 are opposite, through the confluence of the differential planetary gear train, the planet carrier 6 is used as the input of the second stage, driving the pinion shaft 17 to rotate, the pinion shaft 17 The gear shaft 17 is meshed with three large gears 16 evenly distributed on the circumference for transmission to realize flow splitting. The interference fit of the large gears 16 is connected to the output gear shaft 21 for transmission in the circumferential direction, and the output gear shaft 21 is meshed with the ring gear 19 for transmission. To achieve confluence, the ring gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com