Four-module assembled water cellar

A water kiln and water inlet pipe technology, which is applied in the field of four-module assembled water cellars, can solve the problems of poor water storage effect, high maintenance cost, and long construction period, and achieve good appearance quality, reduced transportation costs, and high material and physical properties. Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

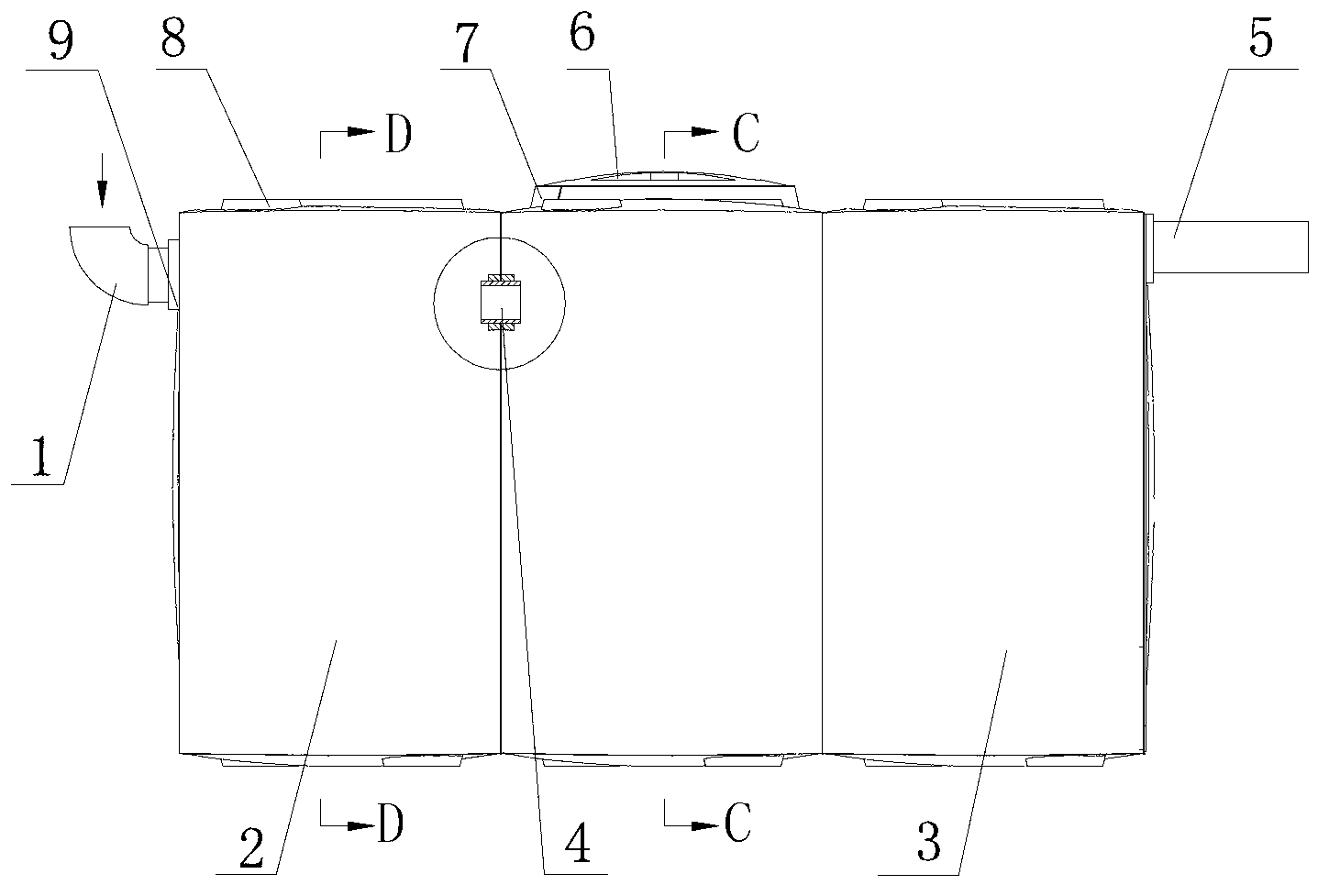

[0021] Such as figure 1 As shown, a four-module assembled water kiln includes a sedimentation tank 2 and a water kiln 3. A water inlet pipe 1 is installed in the sedimentation tank 2, and a connecting pipe 4 is arranged between the sedimentation tank 2 and the water kiln 3. On the top of the water kiln 3, there is Outlet pipe 5.

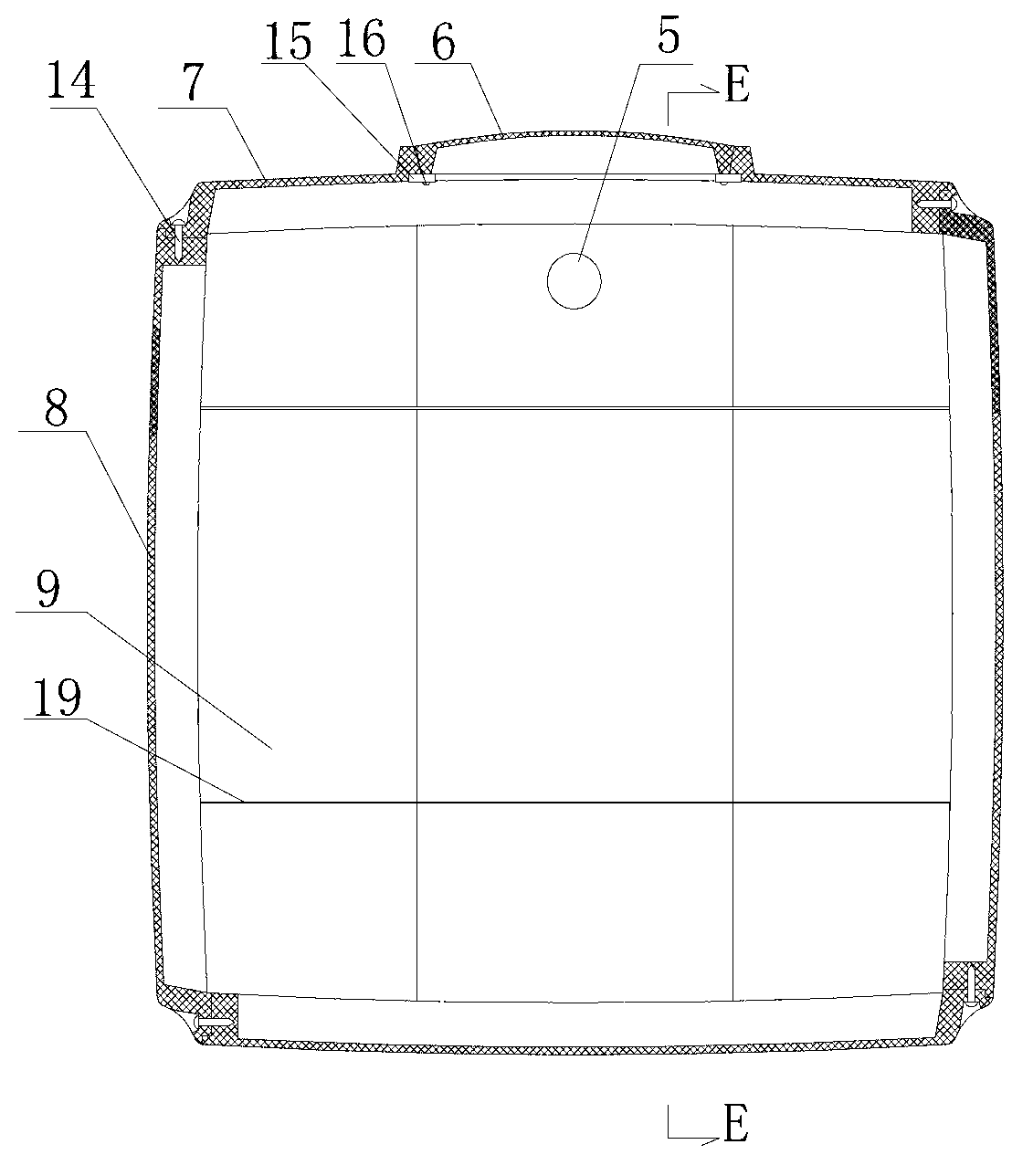

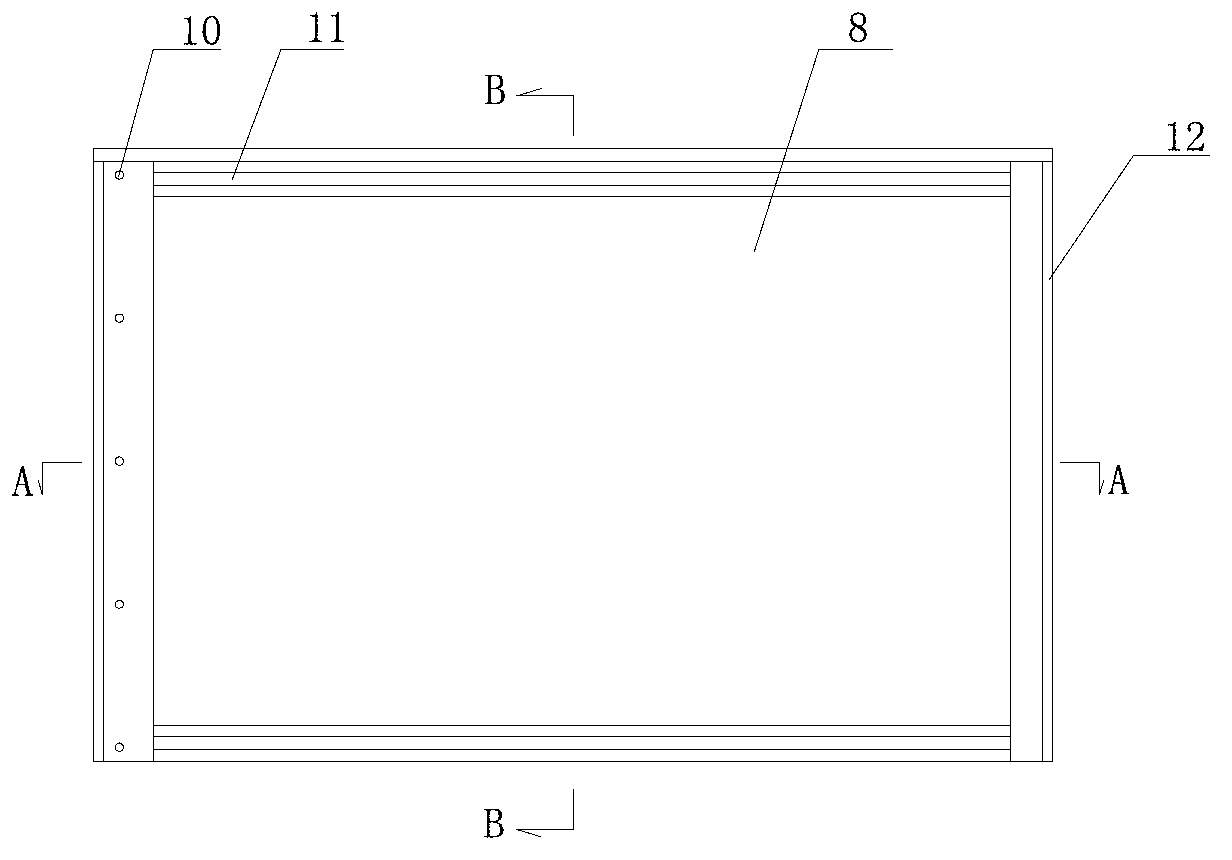

[0022] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 As shown, the side wall 8, the top wall 7, the box cover 6 and the baffle 9, the two ends and both sides of the side wall 8 are provided with matching bayonets 12, and the bolt holes 10 at both ends are 90 to each other. ° position, the bolt holes 13 on both sides are in a straight line; the two ends of the two side panels 8 can be embedded at 90° with each other and fixed with bolts 14, and the two sides of the two side panels 8 can be embedded with each other with bolts 14 is fixed, and baffl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com