A kind of preparation method of polyalkenyl succinimide ashless dispersant

A polyalkenyl succinimide and ashless dispersant technology, applied in the field of oil additives, can solve the problems of high energy consumption and complicated process, and achieve the effects of lower reaction temperature, light color, and good physical and chemical performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

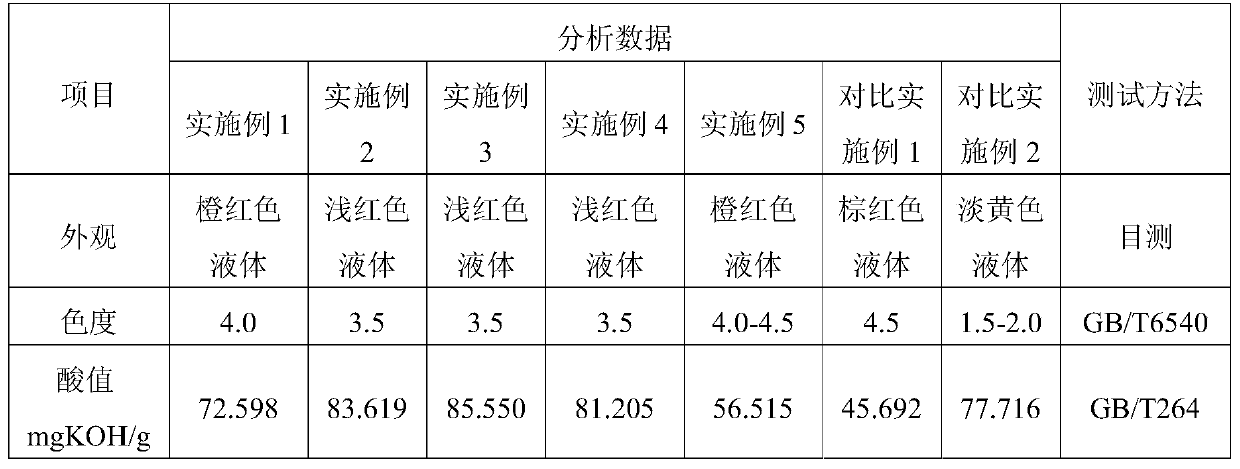

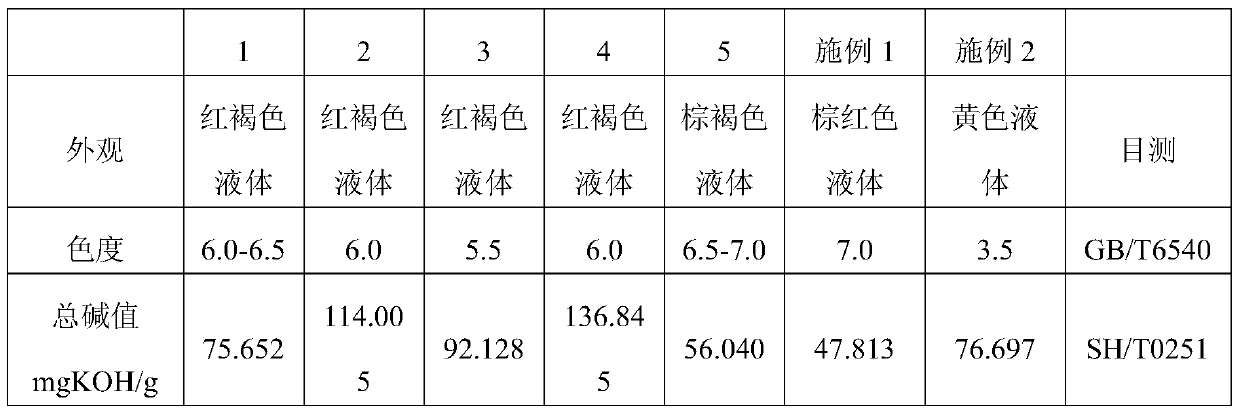

Examples

Embodiment 1

[0036] In a three-necked round-bottom flask with nitrogen protection, add BASF's high-reactive polyisobutylene HRPIB (100g, 0.1mol) with a molecular weight of 1000, maleic anhydride (10.8g, 0.11mol) and dodecylbenzene sulfonic acid (1.0g), magnetically stirred, add di-tert-butyl peroxide (3.0g) at 145° C., react for 4h, stop the reaction. Filter to obtain polyisobutylene succinic anhydride.

[0037] Add polyisobutylene succinic anhydride (100g, 0.09mol) into a three-necked round-bottom flask with nitrogen protection, magnetically stir, pump water under reduced pressure, heat up to 135℃, add heavy polyamine (10g, 0.04mol) dropwise at 160 After reacting at ℃ for 0.5h, the reaction is stopped, and the polyisobutylene succinimide ashless dispersant is obtained.

Embodiment 2

[0039] In a three-necked round-bottom flask with nitrogen protection, a high-reactive polyisobutylene HRPIB (100g, 0.1mol) with a molecular weight of 1000 produced by BASF, maleic anhydride (10.8g, 0.11mol) and dodecylbenzene sulfonic acid were added (1.0g), magnetic stirring, dropwise add a mixed solution of di-tert-butyl peroxide (3.0g) and xylene (75g) at 145°C, react for 4h, and stop the reaction. Filter to obtain polyisobutylene succinic anhydride.

[0040] Add polyisobutylene succinic anhydride (100g, 0.09mol) into a three-necked round-bottom flask with nitrogen protection, magnetically stir, pump water under reduced pressure, heat up to 135℃, add heavy polyamine (23.4g, 0.085mol) dropwise, After reacting at 160°C for 0.5h, the reaction was stopped to obtain the polyisobutylene succinimide ashless dispersant.

Embodiment 3

[0042] In a three-necked round-bottom flask with nitrogen protection, add BASF's high-reactive polyisobutylene HRPIB (100g, 0.1mol) with a molecular weight of 1000, maleic anhydride (17.7g, 0.18mol) and dodecylbenzene sulfonic acid (1.0g), magnetic stirring, dropwise add a mixed solution of di-tert-butyl peroxide (3.0g) and xylene (75g) at 145°C, react for 4h, and stop the reaction. Filter to obtain polyisobutylene succinic anhydride.

[0043] Add polyisobutylene succinic anhydride (100g, 0.09mol) into a three-necked round-bottom flask with nitrogen protection, magnetically stir, pump water under reduced pressure, raise the temperature to 135°C, add pentaethylene hexaamine (9.3g, 0.04mol) dropwise , React at 150°C for 0.5h, stop the reaction, and obtain polyisobutylene succinimide ashless dispersant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com