Determination method of optimal asphalt-stone ratio of asphalt mixture based on road performance

A technology for asphalt mixture and road performance, which is applied in the field of determining the optimal oil-to-stone ratio, and can solve the problems of inability to achieve asphalt mixture road performance, inability to simulate the actual rolling of the road surface, and unqualified asphalt mixture road performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0025] Determination of the best asphalt ratio of AC-13C asphalt mixture

[0026] (1) Selection of raw materials

[0027] 1) New asphalt

[0028] This example uses 70# matrix asphalt as the research object, and its indicators are shown in Table 2.2

[0029] Table 2.170# asphalt performance test results

[0030]

[0031] 2) Mineral grade blending

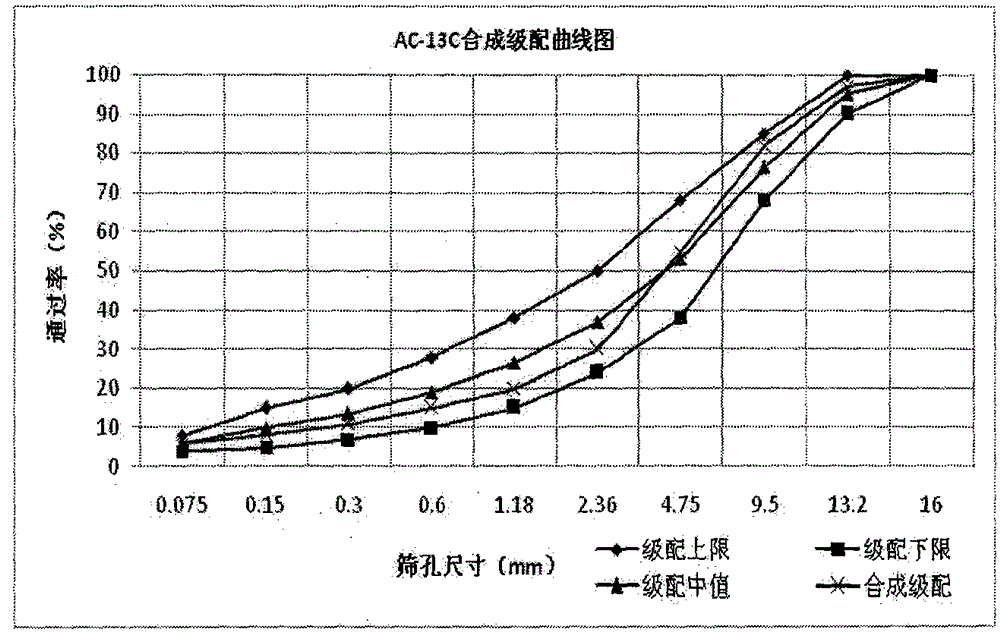

[0032] According to the "Technical Specifications for Highway Asphalt Pavement Construction" (JTGF40-2004) on the AC-13C asphalt mixture, the target gradation is synthesized, and the mineral material gradation is shown in Table 2.1 and figure 1 shown.

[0033] Table 2.2 Synthesis gradation of AC-13C

[0034]

[0035]

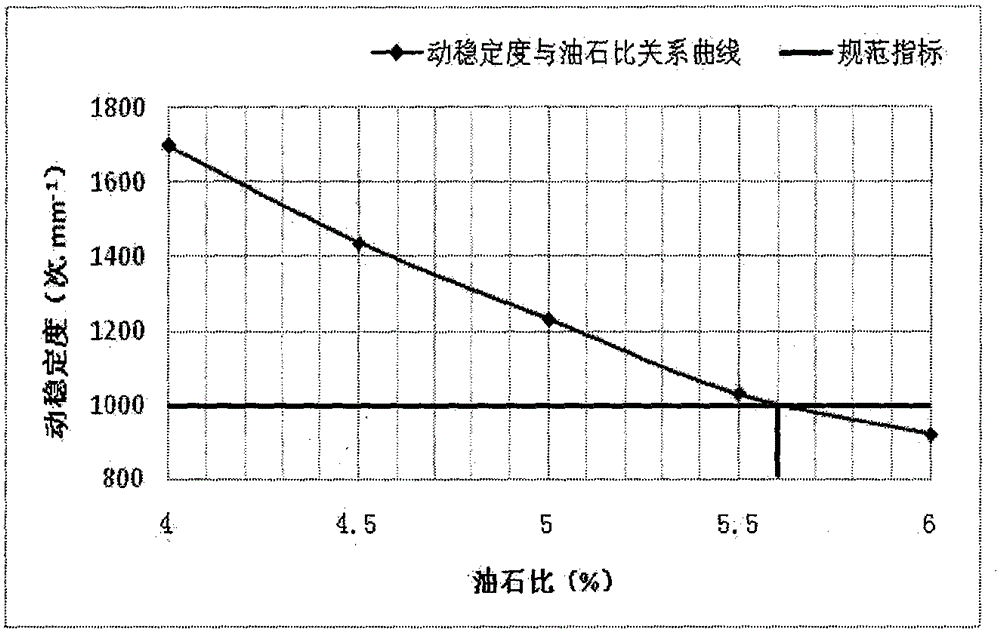

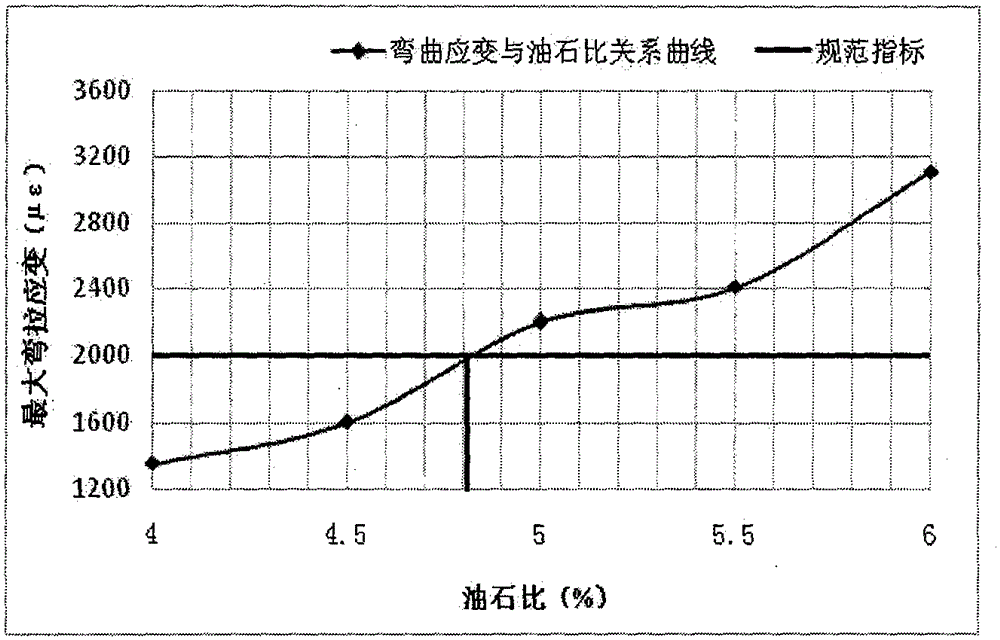

[0036] (2) Determination of the best oil-stone ratio

[0037] Five asphalt ratios of 4.0%, 4.5%, 5.0%, 5.5%, and 6.0% are initially proposed for research on asphalt mixtures. The experimentally determined bulk density at each asphalt ratio is shown in Table 2.3

[0038] Table 2.3 Gross bulk density of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com