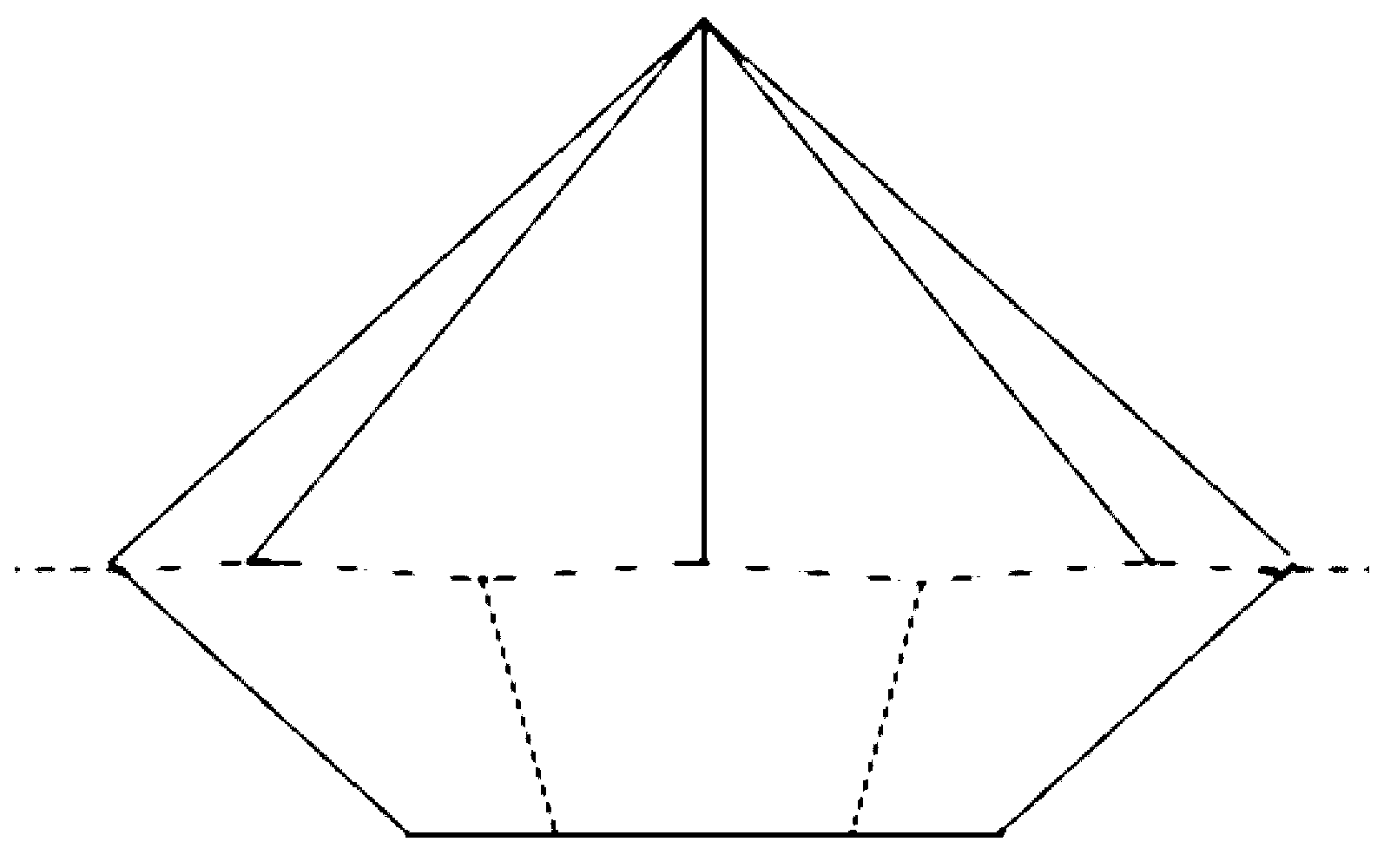

Chemical silvering and pretreatment process for synthetic quartz diamond pavilion

An artificial crystal, chemical silver plating technology, applied in liquid chemical plating, metal material coating process, coating and other directions, to achieve the effect of improving the utilization rate, improving the process, and avoiding yellowing, black and white

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

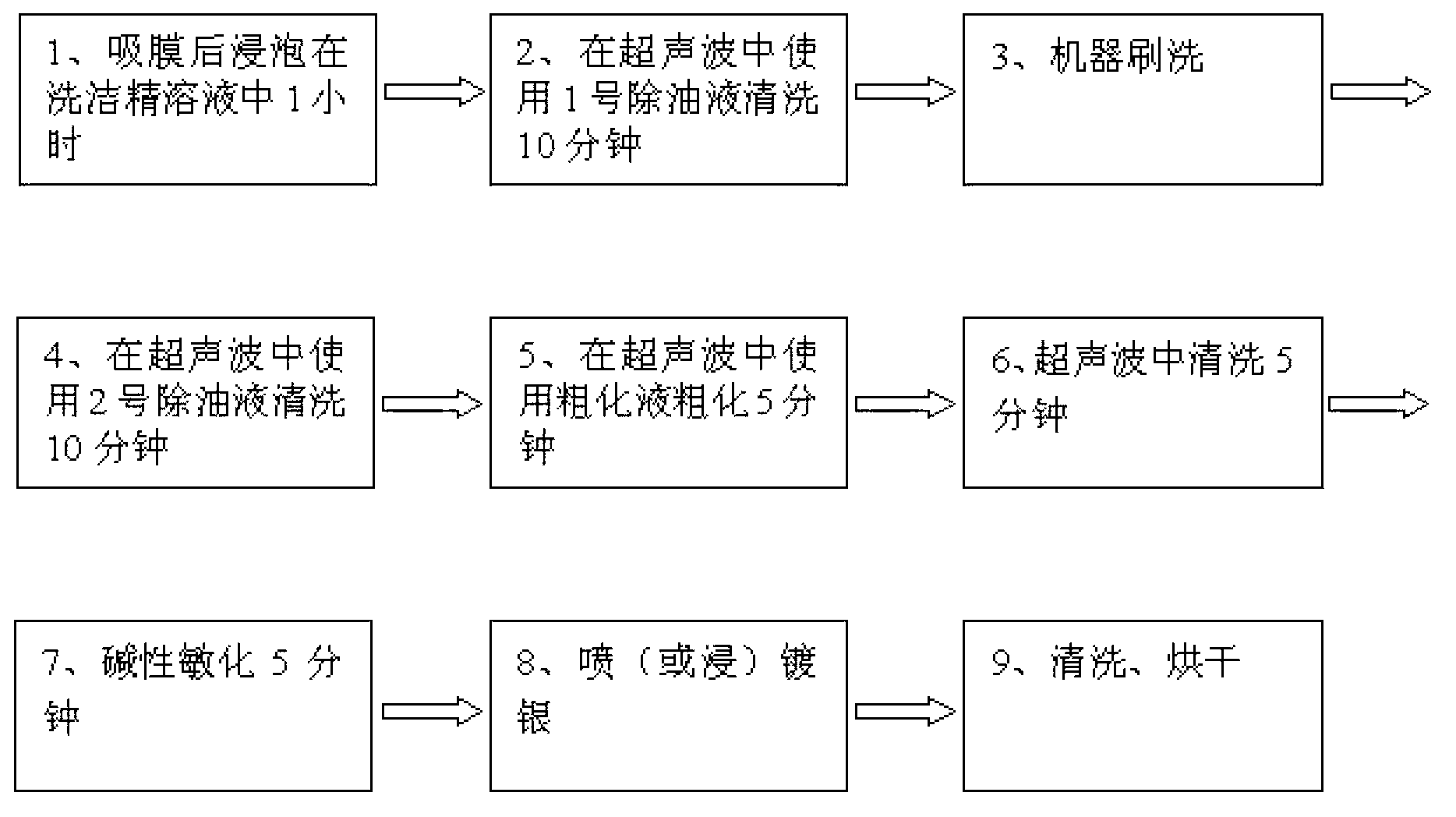

[0041] 4. Put in No. 2 degreasing solution (solution composition: sodium pyrophosphate 1%-5%, sodium carbonate 1%-4%, sodium hydroxide 1%-4%, surfactant 0.1%-3% ) in ultrasonic cleaning for 10 minutes;

[0042] 5. Put in the ultrasonic roughening solution (ammonium bifluoride 0.5%-5%) for 5 minutes, then rinse with water;

[0043] 6. Put it in an ultrasonic wave filled with pure water for 5 minutes, and then rinse it with pure water;

[0044] 7. Put it into a sensitization tank filled with alkaline sensitization solution (1%-4% stannous chloride and 1%-4% sodium hydroxide) for sensitization for 5 minutes;

[0045] 8. During silver plating, No. 1 silver plating solution and No. 1 reducing solution are used for spraying, and the spraying process is carried out according to the spraying process of the prior art. Wherein, the solution composition of the No. 1 silver plating solution is: silver nitrate 1%, ammonia water 2%, sodium hydroxide 0.9%. The solution composition of No. 1 ...

Embodiment 2

[0054] 4. Put in No. 2 degreasing solution (solution composition: sodium pyrophosphate 1%-5%, sodium carbonate 1%-4%, sodium hydroxide 1%-4%, surfactant 0.1%-3% ) in ultrasonic cleaning for 20 minutes;

[0055] 5. Put in the ultrasonic roughening solution (ammonium bifluoride 0.5%-5%) for 5 minutes, then rinse with water;

[0056] 6. Put it in an ultrasonic wave filled with pure water for 10 minutes, then rinse it with pure water;

[0057] 7. Put it into a sensitization tank filled with alkaline sensitization solution (1%-4% stannous chloride and 1%-4% sodium hydroxide) for sensitization for 10 minutes;

[0058] 8. During silver plating, No. 1 silver plating solution and No. 1 reducing solution are used for spraying, and the spraying process is carried out according to the spraying process of the prior art. Wherein, the solution composition of the No. 1 silver plating solution is: silver nitrate 1%, ammonia water 2%, sodium hydroxide 0.9%. The solution composition of No. 1 ...

Embodiment 3

[0067] 4. Put in No. 2 degreasing solution (solution composition: sodium pyrophosphate 1%-5%, sodium carbonate 1%-4%, sodium hydroxide 1%-4%, surfactant 0.1%-3% ) in ultrasonic cleaning for 10 minutes;

[0068] 5. Put in the ultrasonic roughening solution (ammonium bifluoride 0.5%-5%) for 5 minutes, then rinse with water;

[0069] 6. Put it in an ultrasonic wave filled with pure water for 5 minutes, and then rinse it with pure water;

[0070] 7. Put it into a sensitization tank filled with alkaline sensitization solution (1%-4% stannous chloride and 1%-4% sodium hydroxide) for sensitization for 5 minutes;

[0071] 8. No. 2 silver plating solution and No. 2 reducing solution are used for immersion plating during silver plating, and the immersion plating process is carried out according to the immersion plating process of the prior art. Wherein, the solution of the No. 2 silver-plating solution consists of: silver nitrate 1%, ammonia 6%; the solution of the No. 2 reducing solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com