Process for preparing sesame oil

A technology of sesame oil and technology, which is applied in the direction of fat oil/fat production and fat production, can solve the problems of sesame oil sales quantity gap, dark color, etc., and achieve the effect of clear and crystal clear color, reducing pollutants, and natural and pure taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

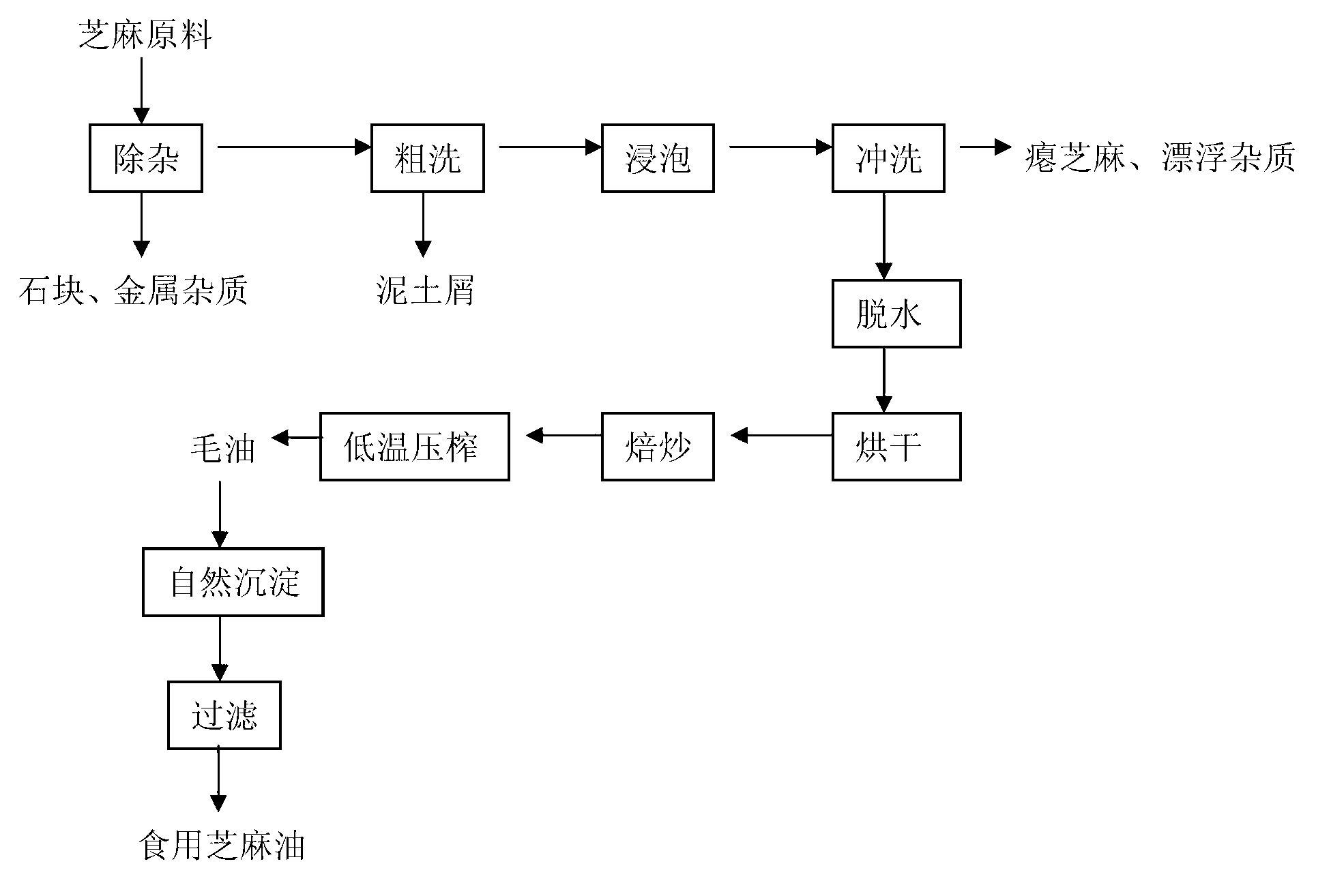

Image

Examples

Embodiment 1

[0031] (1) Pass the sesame raw material through a vibrating screen and a magnetic separator to remove impurities such as small stones, soil, and iron metals, so that the impurity content is less than 0.5%; then use clean flowing water to roughly wash the sesame for 10 minutes to remove the surface of the sesame particles dirt and other impurities; then soak the sesame seeds in a clean water pool for 15 minutes to further remove the impurities attached to the surface of the sesame particles, and remove the shriveled sesame seeds and floating impurities at the same time; then rinse the sesame seeds with clean water for 5 minutes;

[0032] (2) Use a centrifuge to dry the sesame to remove water, so that the moisture content of the sesame is reduced to below 25wt%; then use a drum-type frying pan drying equipment, and the temperature does not exceed 110°C to dry the sesame, and the moisture is reduced to 7wt%;

[0033] (3) Roast the dried sesame seeds at 125°C in a frying pan, and r...

Embodiment 2

[0037] (1) Pass the sesame raw material through a vibrating screen and a magnetic separator to remove impurities such as small stones, soil, iron metals, etc., so that the impurity content is less than 0.5%;

[0038] (2) Roughly wash the sesame seeds with clean running water for 12 minutes to remove impurities such as soil on the surface of the sesame particles; then soak the sesame seeds in a clean water pool for 20 minutes to further remove impurities attached to the surface of the sesame particles, and at the same time shriveled sesame seeds and Floating impurities are removed; then the sesame is rinsed again with clean water for 8 minutes;

[0039] (3) Use a centrifuge to dry the sesame to remove water, so that the moisture content of the sesame is reduced to below 22wt%; then use a drum-type frying pan drying equipment, and the temperature does not exceed 110°C to dry the sesame to reduce the moisture content to 6wt% ;

[0040] (4) Roast the dried sesame seeds at 120°C i...

Embodiment 3

[0044] (1) Pass the sesame raw materials through a vibrating screen and a magnetic separator to remove impurities such as small stones, soil, and iron metals, so that the impurity content is less than 0.5%; use clean flowing water to roughly wash the sesame for 15 minutes to remove the dirt on the surface of the sesame particles Wait for miscellaneous; then soak the sesame seeds in a clean water pool for 30 minutes, further remove the impurities attached to the surface of the sesame particles, and remove the shriveled sesame seeds and floating impurities at the same time; then rinse the sesame seeds again with clean water for 10 minutes;

[0045] (2) Use a centrifuge to dry the sesame to remove water, so that the moisture content of the sesame is reduced to below 20wt%; then use a drum-type frying pan drying equipment, and the temperature does not exceed 105°C to dry the sesame to reduce the moisture content to 5wt% ;

[0046] (3) Roast the dried sesame seeds at 120°C in a fry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com