A kind of nano-aerospace coating and its preparation method and application method

An aviation coating and nano technology, applied in the field of nano aviation coating and its preparation, can solve the problems of low friction, failure to achieve performance indicators, etc., and achieve the effects of long service life, excellent decoration, and high humidity and heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

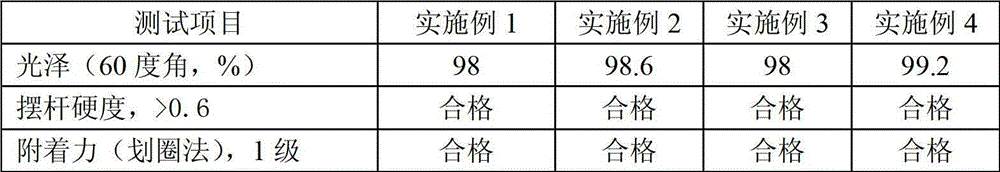

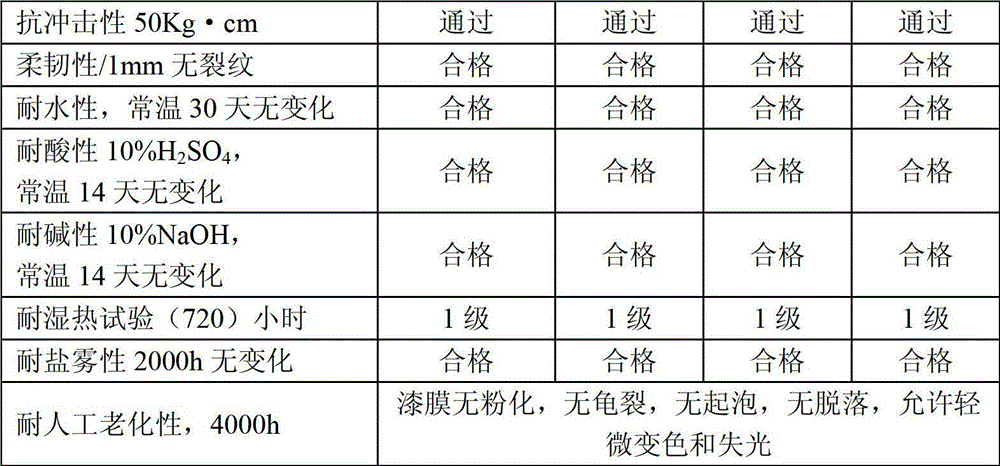

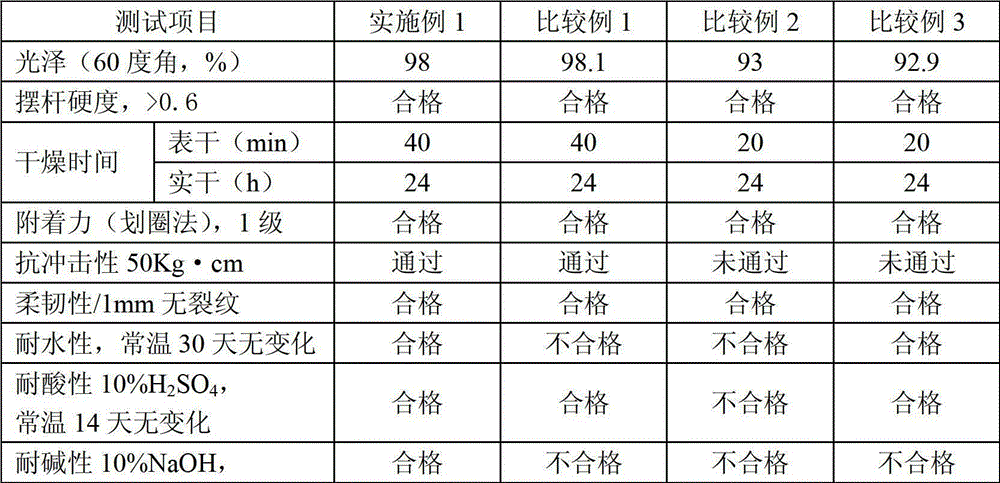

Examples

Embodiment 1

[0032] In a 500ml beaker, add 35 grams of Desmophen651MPA resin, nano-TiO 2 Concentrate slurry 2g, dispersant BYK-1631.2g, mixed solvent 6g, stir well, add titanium dioxide 25g, pre-disperse, grind, when the specified fineness reaches 15μm, add the remaining Desmophen651MPA resin 25g and leveling agent BYK- 3330.2g, defoamer BYK-1410.2g and mixed solvent 5.4g, after stirring evenly, adjust the viscosity, filter, and take samples, component A and component B are prepared according to the mass ratio of 100:30, and tested by various technical indicators, After passing the inspection, measure and pack.

Embodiment 2

[0034] In a 500ml beaker, add 40 grams of Desmophen651MPA resin, nano-TiO 2 Concentrate slurry 4g, dispersant BYK-1632.5g, mixed solvent 10g, stir evenly, add titanium dioxide 1.5g, scarlet 5.5g, carbon black 0.2g, purple red 3.5g, pre-disperse, grind, when the specified fineness is 15μm, Add 25g of remaining Desmophen651MPA resin, 30.3g of leveling agent BYK-3330.3g, 10.3g of defoamer BYK-14 and 7.2g of mixed solvent according to the formula, adjust the viscosity after stirring evenly, filter, and take samples. Component A and component B are 100: 32.5 The quality ratio is used to make the paint, which is measured and packaged after passing the inspection of various technical indicators.

Embodiment 3

[0036] In a 500ml beaker, add 20 grams of Desmophen651MPA resin, nano-TiO 2 Concentrated pulp 2g, dispersant BYK-1630.7g, mixed solvent 6g, after stirring evenly, add 0.2g titanium dioxide, 0.2g scarlet, 0.6g fast yellow, 6g molybdenum orange, 3g medium chrome yellow, pre-disperse, grind, When the specified fineness is 15μm, add the remaining Desmophen651MPA resin 20g, leveling agent BYK-3330.15g, defoamer BYK-1410.15g and mixed solvent 4g according to the formula, stir well, adjust the viscosity, filter, sample, component A and Component B is prepared according to the mass ratio of 100:25. After testing various technical indicators, it is measured and packaged after passing the inspection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com