Soil amendment for cold waterlogged paddy field

A soil conditioner and cold-soaking field technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve problems such as labor-intensive, time-consuming, expensive, and base ion loss, so as to increase economic benefits, reduce adverse effects, and promote The effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A cold soaking field soil improver, which is composed of two components: A and B:

[0020] Described group A is to be made from the raw material of following weight (kg):

[0021] Furnace ash 55, blast furnace slag 10, attapulgite 25, gypsum 5, calcium magnesium phosphate fertilizer 4, zinc sulfate 0.5, borax 0.5.

[0022] The preparation method of the component A is as follows: the furnace ash is ground through a 10-mesh sieve, the attapulgite, gypsum, and blast furnace slag are ground through a 20-mesh sieve, and the above-mentioned raw materials in parts by weight are uniformly mixed to obtain the component A;

[0023] The said component B is obtained by anaerobic carbonization of rice husk at 400-450°C.

[0024] When applying the improver, first spread component A evenly on the ground surface at an application rate of 300 kg per mu before soil preparation, and then pour it into the soil and mix it fully with the soil when preparing the soil; Apply to water surface...

Embodiment 2

[0029] Described group A is to be made from the raw material of following weight (kg):

[0030] Furnace ash 60, blast furnace slag 15, attapulgite 15, gypsum 5, calcium magnesium phosphate fertilizer 4, zinc sulfate 0.5, borax 0.5.

[0031] The preparation method of the component A is as follows: the furnace ash is ground through a 10-mesh sieve, the attapulgite, gypsum, and blast furnace slag are ground through a 20-mesh sieve, and the above-mentioned raw materials in parts by weight are uniformly mixed to obtain the component A;

[0032] The said component B is obtained by anaerobic carbonization of corn stalks at 300-350°C.

[0033] When applying the improver, firstly spread the component A on the surface of the ground according to the application rate of 350 kg per mu evenly before the soil preparation, and then pour it into the soil and mix it fully with the soil during the soil preparation; Apply to water surface.

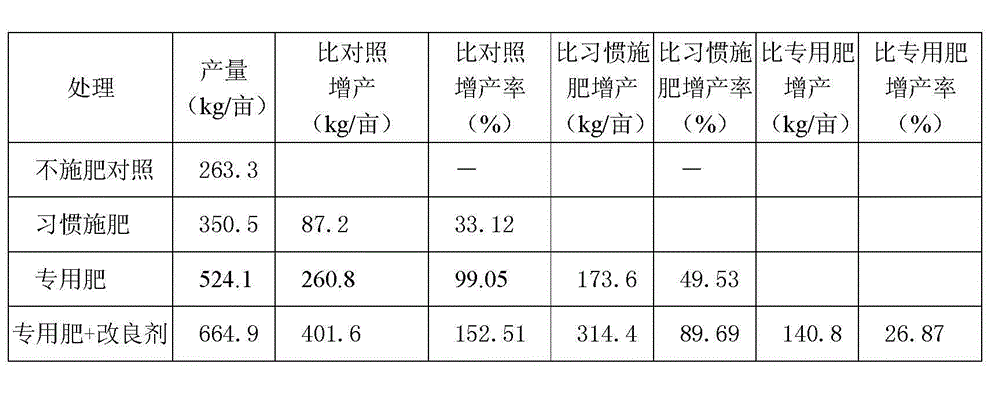

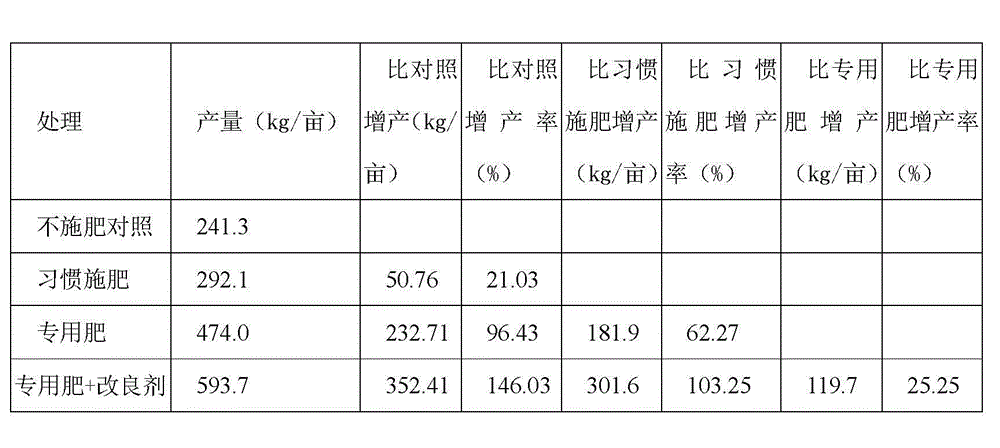

[0034] The place of implementation is in Shexian Coun...

Embodiment 3

[0038] Described group A is to be made from the raw material of following weight (kg):

[0039] Furnace ash 55, blast furnace slag 15, attapulgite 20, gypsum 5, calcium magnesium phosphate fertilizer 4, zinc sulfate 0.5, borax 0.5.

[0040] The preparation method of the component A is as follows: the furnace ash is ground through a 10-mesh sieve, the attapulgite, gypsum, and blast furnace slag are ground through a 20-mesh sieve, and the above-mentioned raw materials in parts by weight are uniformly mixed to obtain the component A;

[0041] The said component B is obtained by anaerobic carbonization of rice husk at 400-450°C.

[0042] When applying the improver, first spread component A evenly on the ground surface at an application rate of 300 kg per mu before soil preparation, and then pour it into the soil and mix it fully with the soil when preparing the soil; Apply to water surface.

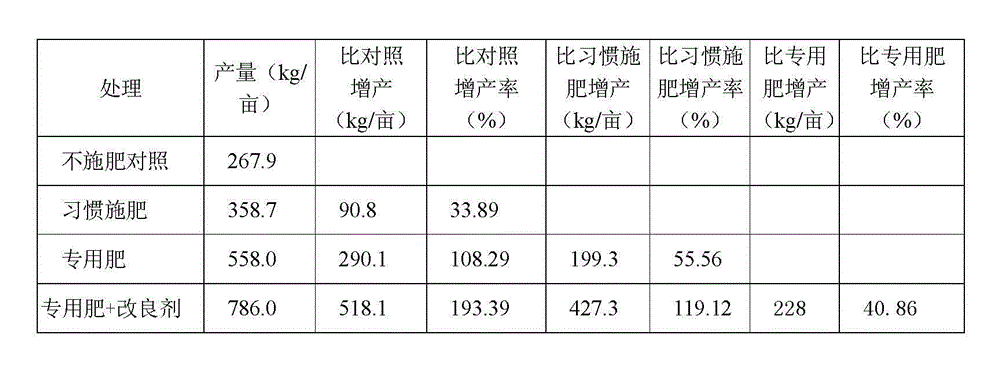

[0043] The implementation site is Huangshan City, Anhui Province, and the tested variet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com