Capillary forming method for preparing super oleophobic surface

A technology of super-oleophobic and forming method, which is applied in capillary forming method, preparation of super-oleophobic surface, and preparation of polymer super-oleophobic surface, which can solve complex preparation process, poor controllability, depth of secondary groove structure Limited and other problems, to achieve the effect of low preparation cost, simple equipment, and easy batch preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

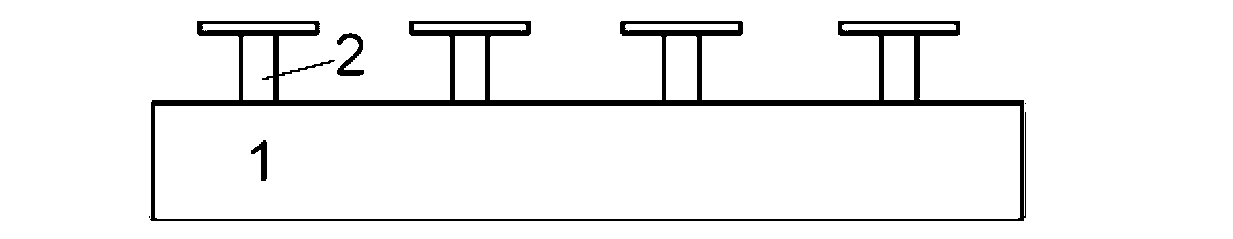

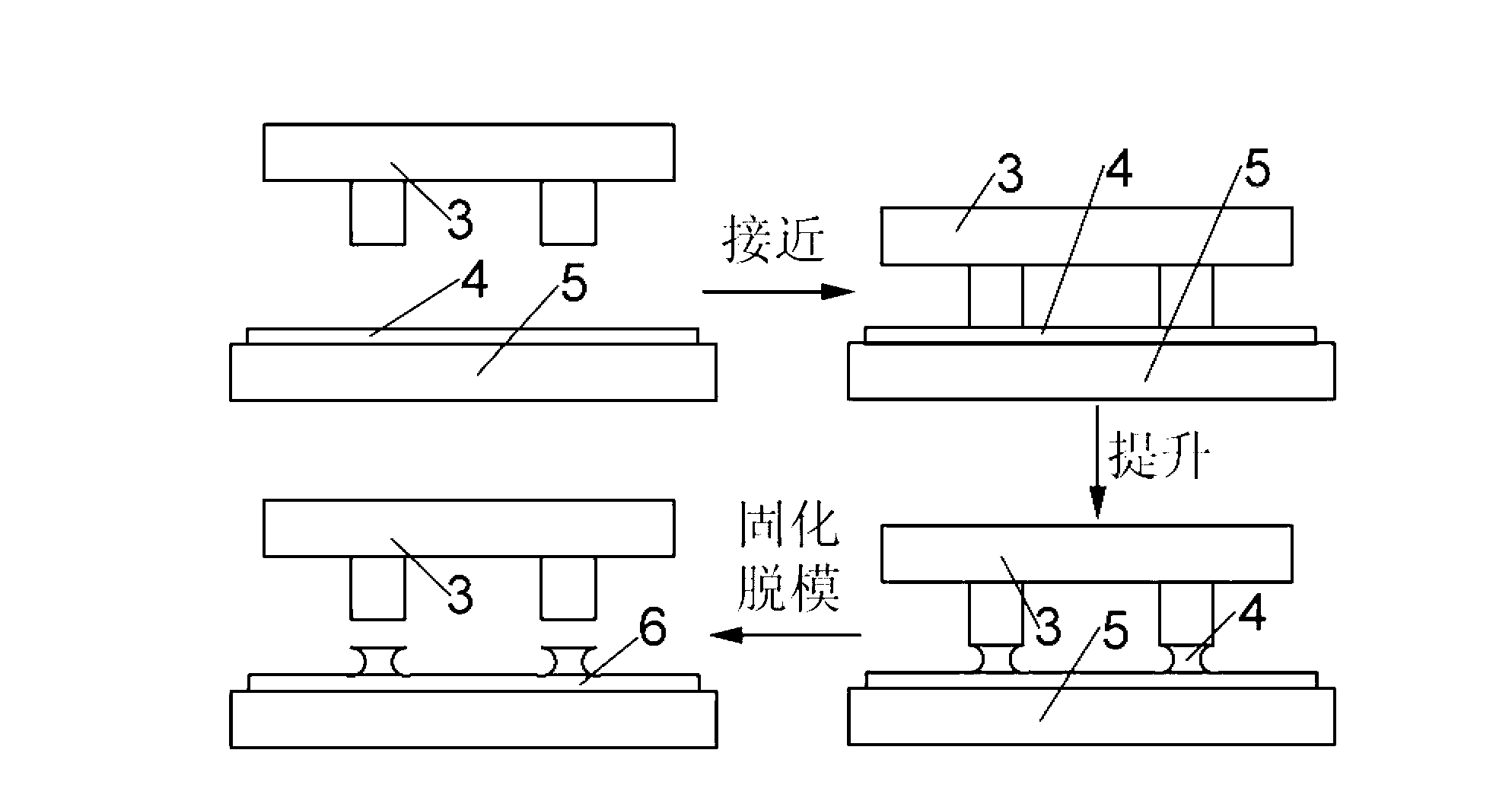

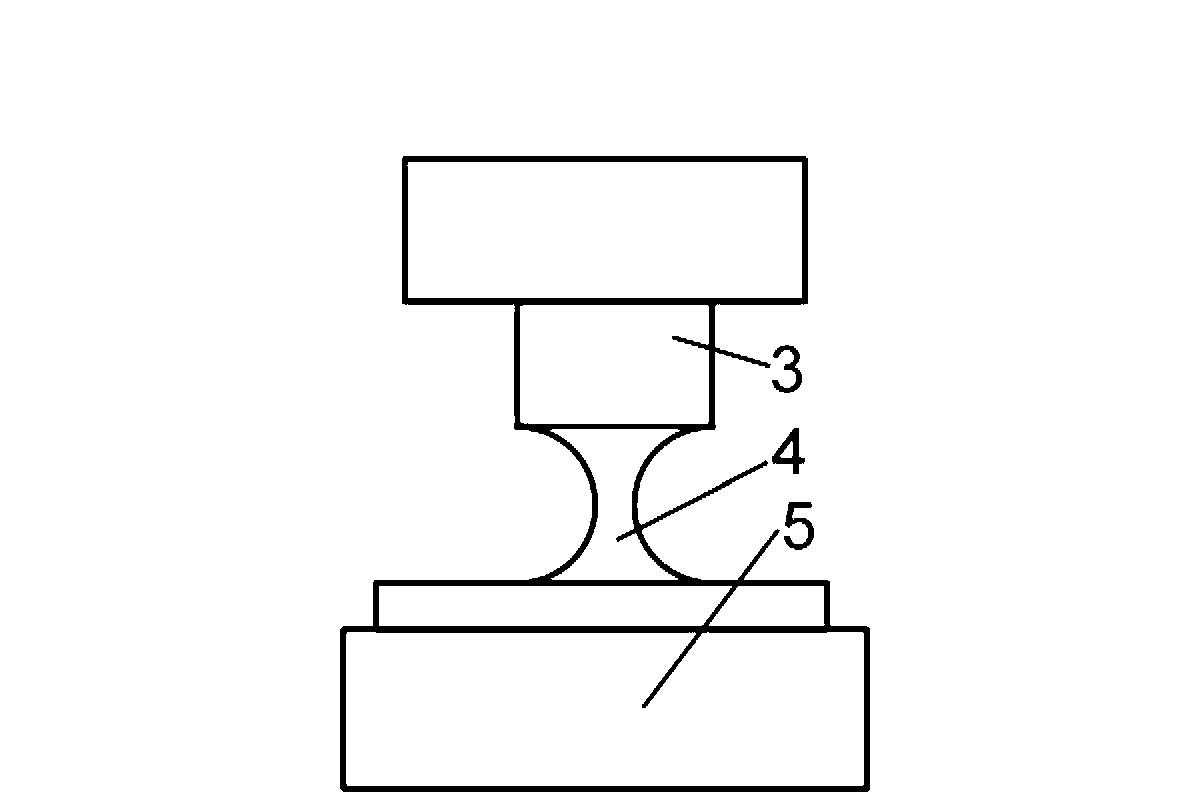

[0033] The micro-nano structure template is prepared by using a silicon substrate template through a photolithographic processing method, which is a mature micro-nano processing technology, and will not be described in detail here. The micro-nano structure of the prepared template is as follows: the structural form is a cylinder array, the diameter of the micro cylinder is 30 μm, the height is 50 μm, and the distance between the columns is 100 μm.

[0034] Both the liquid polymer and the smooth and flat substrate are made of PDMS. First, the two formulations of PDMS are weighed at a ratio of 10:1. After the two formulations are fully mixed, ~50 μL is poured on a smooth silicon wafer surface to prepare a smooth and flat substrate. As the substrate, place the silicon wafer on a horizontal surface. After the free spreading of PDMS is completed, send the silicon wafer loaded with PDMS into a vacuum drying oven, and place it in an environment of 60°C for 2 hours. The PDMS replica w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com