Cable-stayed beam assembly of concrete mixer truck frame

A technology for mixing trucks and concrete, applied in concrete transportation and other directions, can solve the problems of easy deformation stress and concentration, and achieve the effects of avoiding fracture, reducing impact force and improving stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

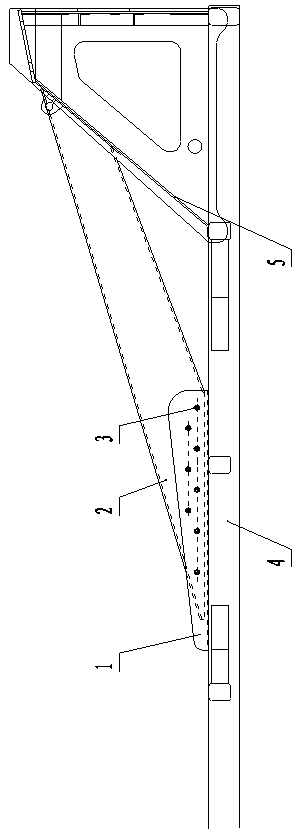

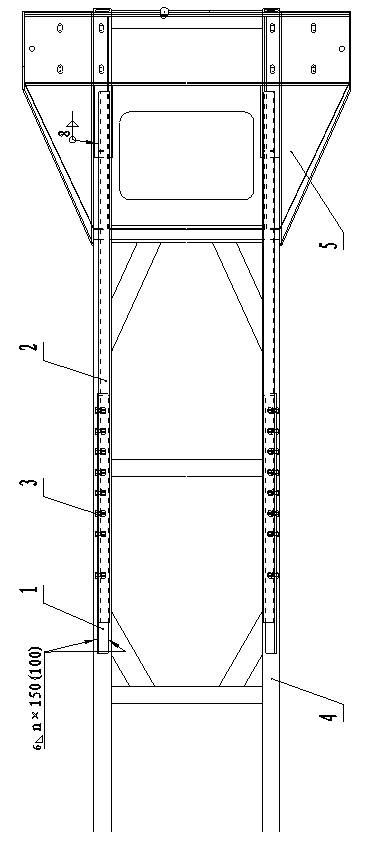

[0015] figure 1 and figure 2 The shown concrete mixer truck frame cable-stayed beam assembly has two groups of cable-stayed beam assemblies symmetrically arranged on the frame. 2 and the inclined-stayed plate support 1 welded on the vehicle frame longitudinal beam 4, the inclined-stayed plate 2 and the inclined-stayed plate support 1 are connected and fixed by two rows of bolts 3 arranged staggeredly. When welding, install the cable-stayed beam assembly to the corresponding position, so that the cable-stayed plate support 1 is attached to the frame longitudinal beam 4, and the cable-stayed plate 2 is bonded to the front sealing plate 5 of the backstage; on the cable-stayed plate support 1 Between the frame longitudinal beam 4 and the long sides of the inclined plate support 1, an intermittent fillet weld is formed. The fillet size of the intermittent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com