A method for double-sided anti-dyeing indigo calico

A calico and double-sided technology, applied in printing, printing plates, printing foils, etc., can solve problems affecting the quality of squeegee, not smooth enough, insufficient light control, etc., and achieve simple and easy process steps and light transmission Good, improve the effect of printing and dyeing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

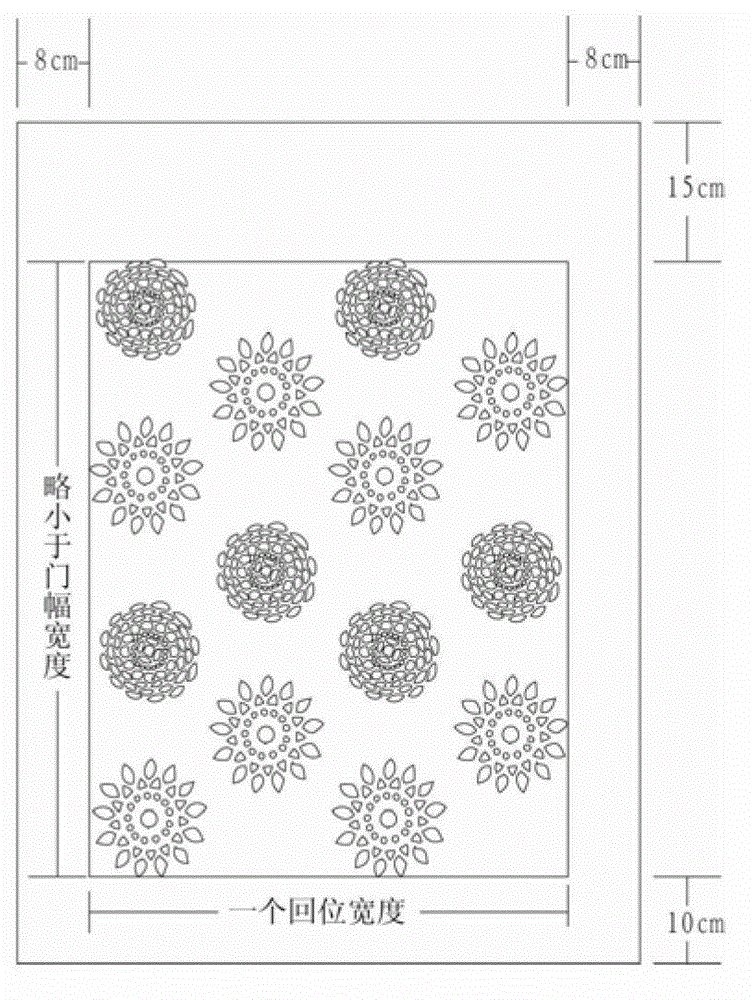

[0027] (1) To make a light-transmitting stamp pad, the height of the stamp pad can generally be set to 75cm, the width to 58cm, and the length to 124cm, plus other supporting objects such as brackets. Attached are illustrations. The top of the printing pad is made of transparent glass with a thickness of not less than 5mm, which is tightly embedded in the wooden frame. A closed and opaque glass light box is made below, and 5 fluorescent tubes are installed inside, and each is controlled by a separate switch.

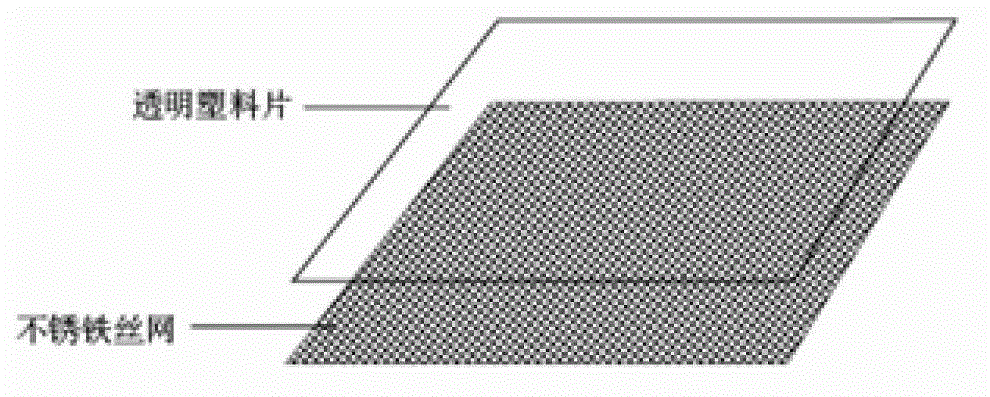

[0028] (2) On the top of the transparent glass printing pad, fix a relatively flat and light-transmitting stainless steel wire mesh, the size of which is the same as the surface of the printing pad. The mesh can generally be 40 mesh, the wire diameter is 0.1mm, and the light transmission is suitable as the standard.

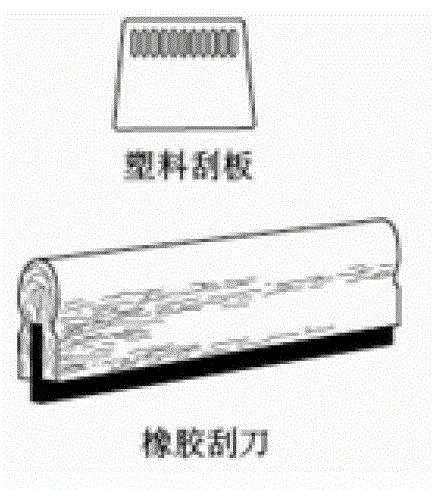

[0029] (3) Due to the unevenness of the stainless steel mesh, in order to facilitate the scraping of the printing paste, a 1mm-2mm thick transparent plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com