Novel anti-impact light interlayer structure

A sandwich structure, impact-resistant technology, applied in the field of sandwich structures, can solve the problems of reducing mobility, energy consumption, and no economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

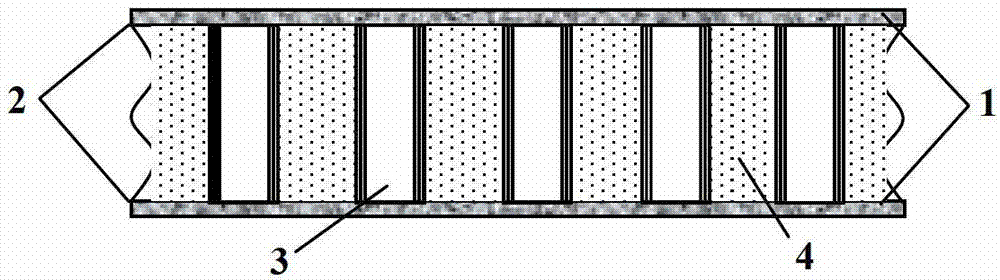

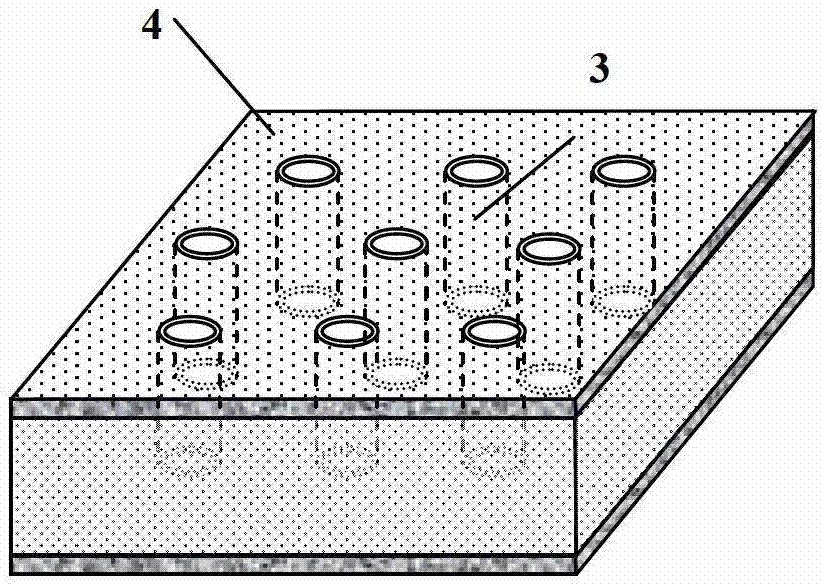

[0062] Panel; 2. Resin layer; 3. Composite pipe; 4. Foam;

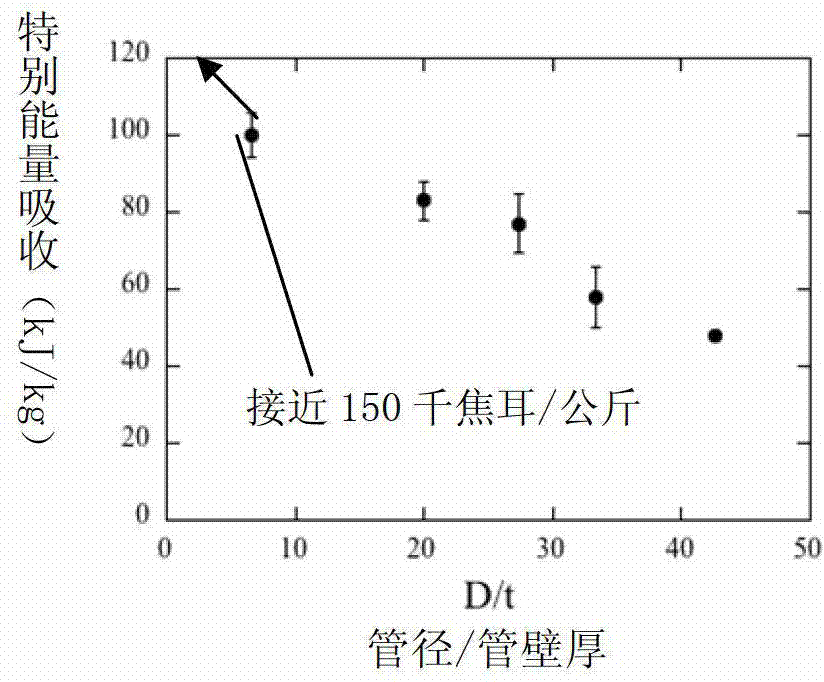

[0063] Such as figure 1 with figure 2 As shown, the novel lightweight impact-resistant sandwich structure of the present embodiment comprises carbon fiber panels 1 (density: 1400kg / m 3 , thickness: 0.3mm, size: 150x150mm 2 , modulus of elasticity: 55GPa, ultimate tensile stress: 850MPa, ultimate tensile strain: 0.05, Poisson’s ratio: 0.07), with PVC foam 4 between two carbon fiber panels 1 (density: 80kg / m 3 , thickness: 10mm, elastic modulus: 70MPa, yield stress: 2MPa, compressive ultimate stress: 3MPa, compressive ultimate strain: 0.7, Poisson’s ratio: 0.35) As a sandwich material, PVC foam 4 and carbon fiber panel 1 are bonded by resin layer 2 A carbon fiber tube (diameter / tube wall thickness ratio: 7-43, quantity: 16, material parameters the same as the panel) is embedded between the PVC foam 4 as the composite tube 3 . The sandwich structure withstands the explosion of 38gPE4 explosive. Such as image 3 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com