Small masterbatch drying device

A drying device, technology of color masterbatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

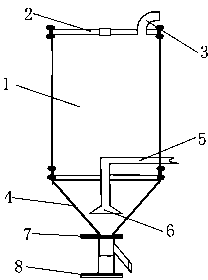

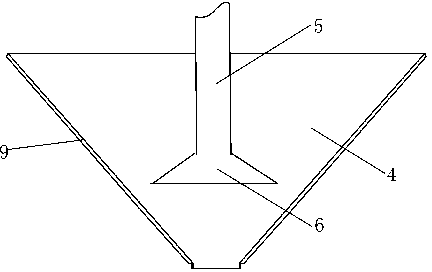

[0014] Combine below figure 1 and figure 2 Specific description embodiment:

[0015] A small-sized color masterbatch drying device, comprising a thermal insulation barrel 1, the upper end of the thermal insulation barrel 1 is provided with a bung 2, and the described bung 2 is provided with an exhaust hole 3, and the thermal insulation barrel 1 The lower end is connected with a conical barrel 4, and the side wall of the heat preservation barrel body 1 is provided with a dry hot air delivery pipe 5, and the dry hot air delivery pipe 5 enters the heat preservation barrel body 1 and extends into the conical barrel 4, One end of the hot and dry air delivery pipe 5 located in the conical barrel 4 is provided with a trumpet-shaped air outlet 6, the bottom of the conical barrel 4 is provided with a flapper valve 7, and the bottom of the flapper valve 7 is provided with Screening screen 8.

[0016] Preferably, the inner wall of the tapered barrel 4 is provided with a filter screen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com