Automatic continuous inner hole polishing machine for steel tubes

A polishing machine, steel pipe technology, applied in the direction of surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

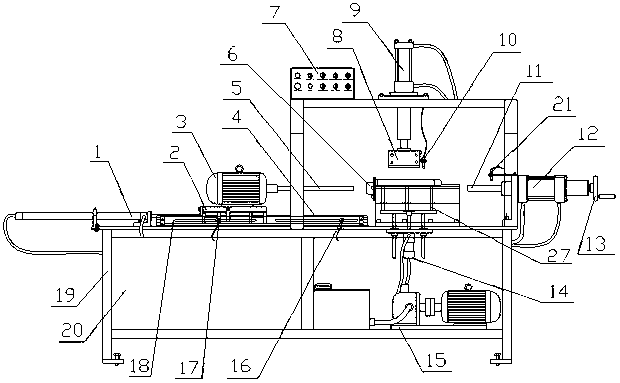

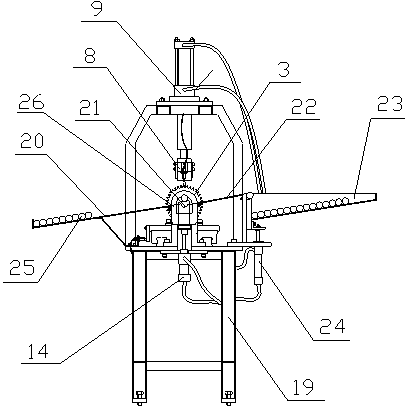

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] An automatic continuous inner hole polishing machine for steel pipes, comprising a frame 19 and a workbench on the upper part of the frame 19, the inside of the frame 19 is provided with an electric control device 20 and a hydraulic device 15, and the workbench is provided with Fixing device, sample transporting device and polishing device, the electric control device 20 is respectively connected with the fixing device, sample transporting device and polishing device through the hydraulic device 15 . The fixing device comprises a pressing die 8, a pressing lower die 26 and a positioning rod 11, the pressing upper die 8 is provided with a pressing oil cylinder 9, and the lower pressing die 26 is provided with a discharge The oil cylinder 14; the pressing lower die 26 is composed of polyurethane in the inner layer and steel in the outer layer. The sample conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com