Heavy rotary supporting roller frame

A technology of rotating supporting rollers and supporting roller frames, which is applied in the field of machine tools, and can solve problems such as complex structure of supporting rollers, broken screw rods, and low service life, so as to overcome low utilization rate of equipment, facilitate installation and disassembly, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

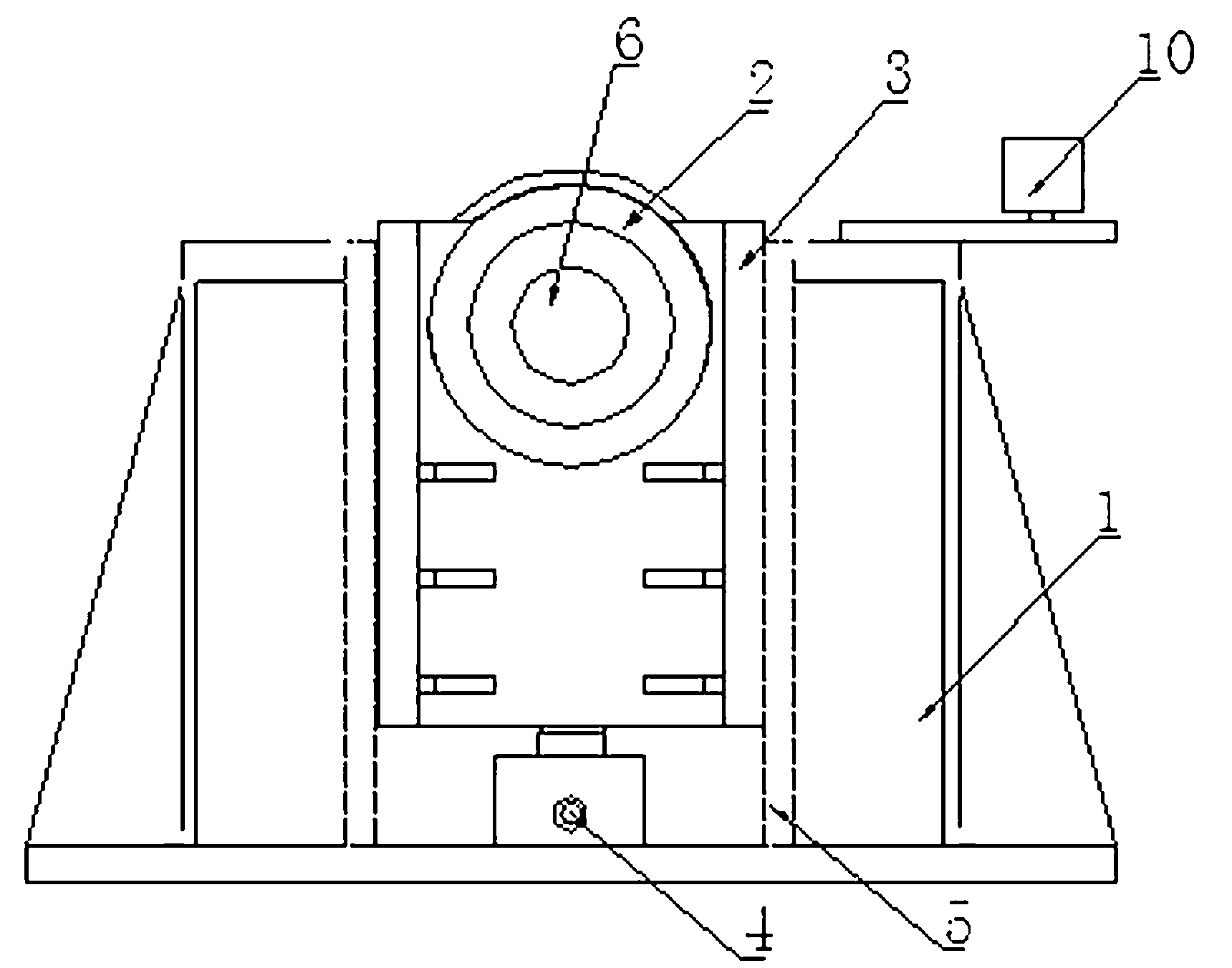

[0035] A heavy-duty rotating roller frame, comprising a base body 1, a decelerating motor, a supporting wheel 2 and a supporting wheel support frame 3, a groove is opened on the base body 1, and a self-locking jack 4 is fixedly arranged at the bottom of the groove, so that The self-locking jack 4 is fixedly connected to the bottom of the supporting roller support frame 3, and the supporting roller supporting frame 3 is slidably arranged in the groove; The supporting surface is higher than the supporting wheel support frame 3, and the power output shaft of the geared motor is connected with the supporting wheel 2.

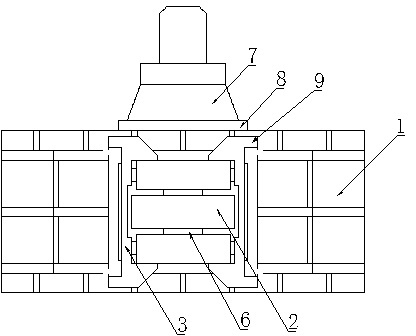

[0036] The preferred implementation mode of this embodiment is that the upper part of the supporting wheel support frame 3 is provided with an inner cavity, and a rotating shaft 6 is arranged between the two side walls of the inner cavity, and the two ends of the rotating shaft 6 move with the supporting wheel supporting frame 3 through bearings. connected, the supp...

Embodiment 2

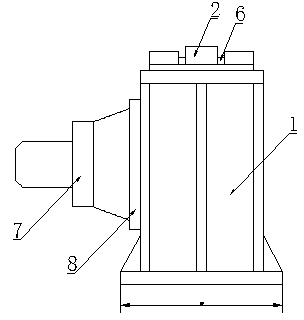

[0046] This embodiment is basically the same as the above-mentioned embodiment, the main difference is: the base body 1 is a trapezoidal structure, the height of the base body 1 is 0.6m, the length of the upper side of the base body 1 is 0.8m, and the length of the lower side of the base body 1 is 1.2m. The thickness of the seat body 1 is 0.5m.

Embodiment 3

[0048] This embodiment is basically the same as the above-mentioned embodiment, the main difference is that: the upper side of the seat body 1 is provided with a limiting wheel 10 .

[0049] In the present invention, the working support surface of the support roller 2 refers to the contact surface with the metal piece to be processed.

[0050] The working principle of the present invention is: according to the size of the metal parts to be processed, the positions of four supporting rollers are symmetrically set, wherein, the supporting rollers 2 on the four supporting rollers are located on the arc of the same circle. Place the metal parts to be processed on the four supporting wheels 2, start the self-locking jack 4 and the cycloid reducer 7, adjust the metal parts to a suitable height and processing position, and start the boring and milling machine to process the metal parts , During the processing, the height and level of the metal parts can be fine-tuned according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com