Aggregate angularity on-site real-time monitoring device

A real-time monitoring and aggregate technology, applied to the analysis of materials, instruments, etc., can solve the problems of low efficiency, inability to detect the angular state of aggregates in real time, and large labor load, and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

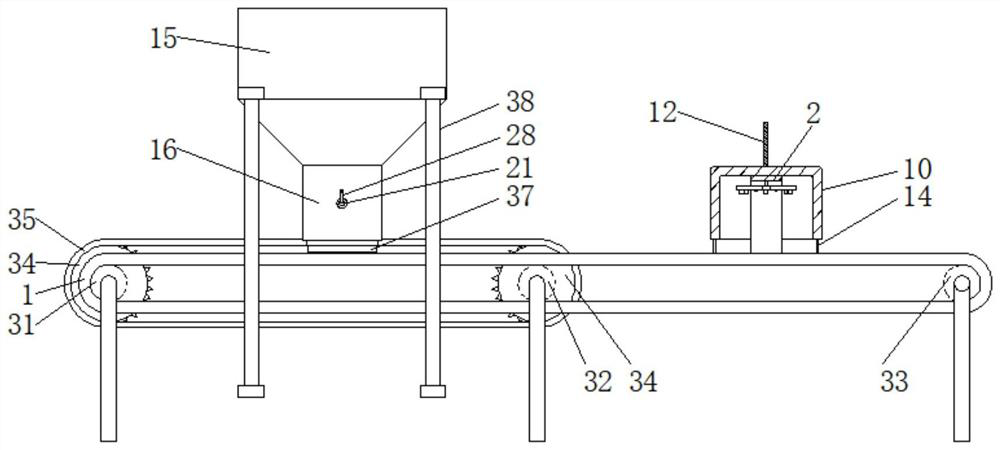

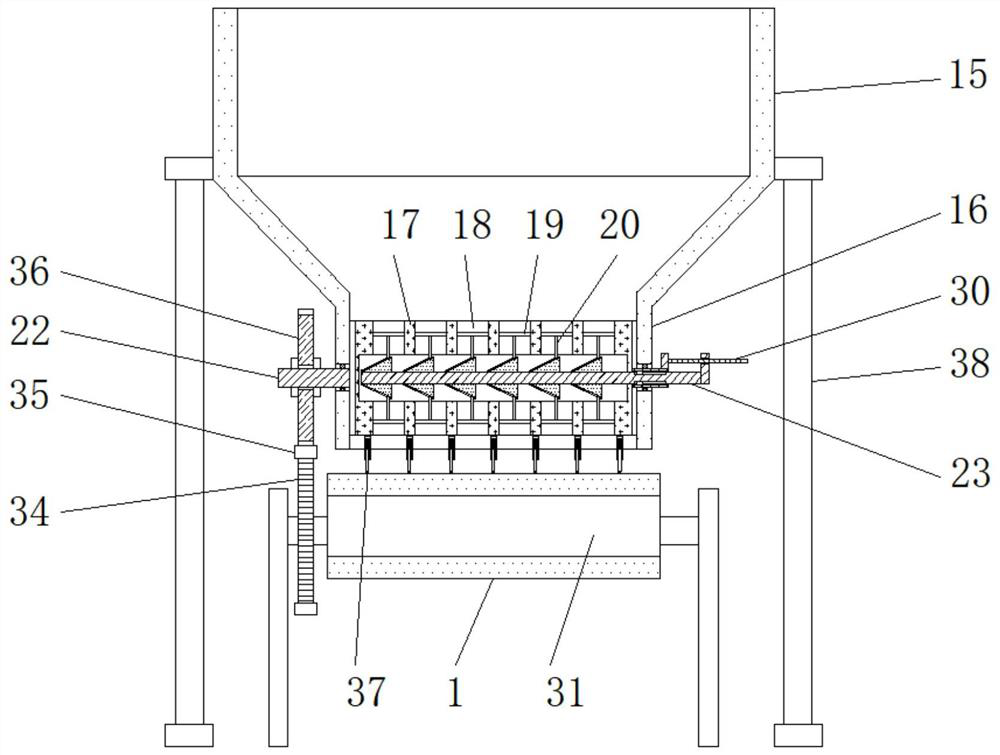

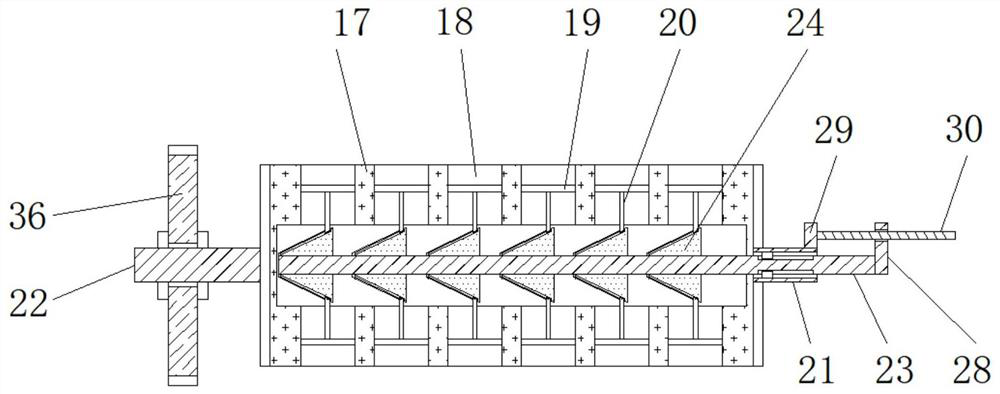

[0039] Such as figure 1 The on-site real-time monitoring device for the angularity of aggregates shown includes a conveyor belt 1 for conveying aggregates, a fixed bracket for installing the conveyor belt 1, a set of rotating rollers installed on the bracket and driving the conveyor belt 1 to rotate, and the conveyor belt 1. Directly above, there is a distributing mechanism erected on both sides of the fixed support that can evenly and stably distribute the aggregate on the conveyor belt 1, and the fixed support is equipped with an image acquisition mechanism 2 that takes pictures of the dispersed aggregate, and the image acquisition Mechanism 2 is provided with a covering mechanism for shading aggregates during shooting, and a detection mechanism 4 for testing materials after photographing is provided under the forward end of conveyor belt 1, and a detection mechanism 4 for testing aggregates after photographing is provided under the forward end of conveyor belt 1. Undertake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com