Automatic circular mould perforating machine

A technology of punching machine and ring die, applied in the field of punching machine, can solve the problems of poor consistency and stability of the die hole of the ring die, affecting the overall quality of the ring die, and the influence of human factors, etc. Consistency and stability of the holes, and the effect of convenient continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

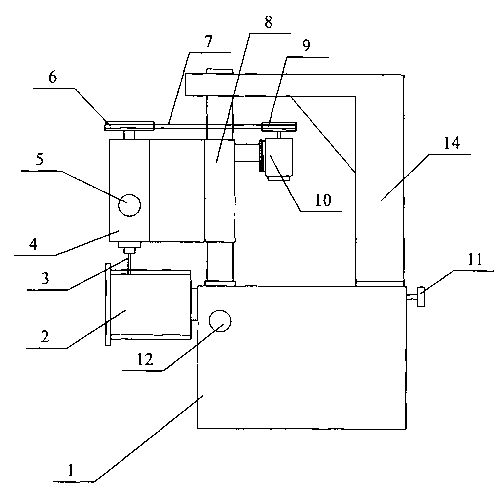

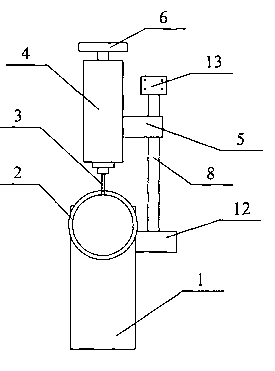

[0020] Such as figure 1 and figure 2 As shown, an automatic ring die punching machine includes a machine base 1, a drill bit 3, a drill bit power head 4, a first servo motor 5, a slide rail 8, a main motor 10, an indexing head 11, a second servo motor 12, Control box 13 and slide rail mount 14. Drill bit 3 is arranged on the power output end of drill bit power head 4, and the power output end of main motor 10 is connected with the power input end of drill bit power head 4 by driving wheel 9, belt 7, driven wheel 6. One end of the first servo motor 5 is connected to the drill head 4 , and the other end of the first servo motor 5 is slidably connected to the slide rail 8 . The slide rail 8 is fixedly connected to the machine base 1 through the slide rail mount 14 . The control box 13 is electrically connected with the main motor 10 and the first servo motor 5 . Both the second servo motor 12 and the indexing head 11 are installed on the machine base 1 . The second servo mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com