Silver/silver phosphate composite material and preparation method thereof

A composite material and silver phosphate technology, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of low utilization rate of sunlight, etc., and achieve simple and easy preparation methods and mild synthesis conditions , is conducive to the effect of large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

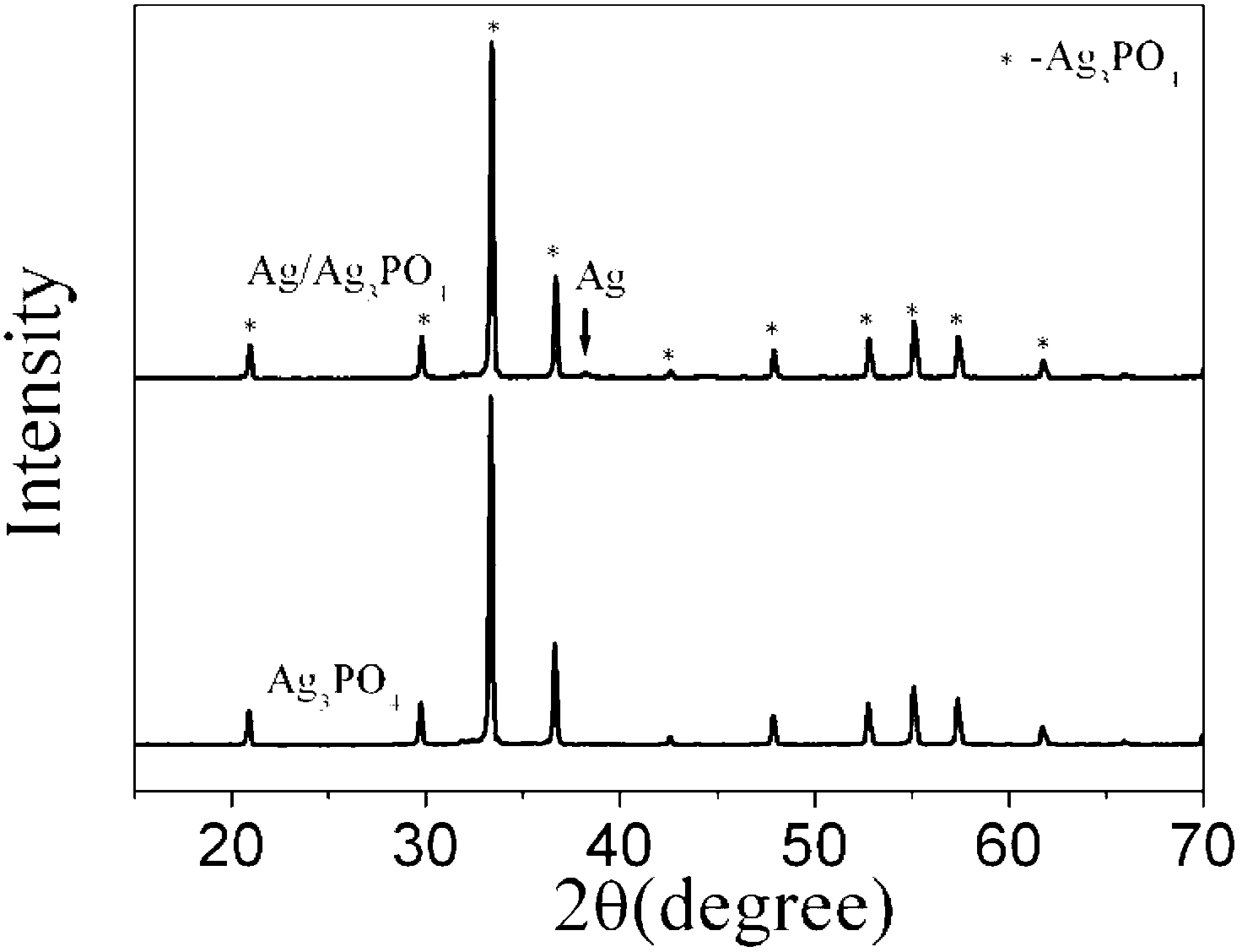

Image

Examples

Embodiment 1

[0018] Dissolve 1.42g disodium hydrogen phosphate in 100mL deionized water to make 0.1mol / L disodium hydrogen phosphate solution A; dissolve 4.98g silver acetate solution in 300mL deionized water to make 0.1mol / L silver acetate solution B: Mix the above-mentioned solutions A and B uniformly according to the molar ratio of 1:3 under stirring state, centrifuge washing after standing, and dry at 80°C for 12h. Disperse silver phosphate and sodium fluoride in absolute ethanol according to the molar ratio of silver phosphate, sodium fluoride, and absolute ethanol at 0.001:0.001:1, then move to the reaction kettle, place in a microwave reactor and heat to 150 ℃ microwave solvent heat treatment for 0.5h, take it out and cool it down to room temperature naturally, centrifuge the obtained product, wash it with deionized water three times, and dry it at 80℃ for 12h to obtain a silver / silver phosphate composite material.

Embodiment 2

[0020] Dissolve 7.1g of disodium hydrogen phosphate in 100mL of deionized water to make 0.5mol / L disodium hydrogen phosphate solution A; dissolve 24.9g of silver acetate solution in 300mL of deionized water to make 0.5mol / L of silver acetate Solution B: Mix the above two solutions A and B uniformly according to the molar ratio of 1:3 under stirring, and then centrifugally wash and dry at 80°C for 12 hours after standing still. Disperse silver phosphate and sodium fluoride in absolute ethanol according to the molar ratio of silver phosphate, sodium fluoride, and absolute ethanol at 0.005:0.005:1, then move to the reaction kettle, place in a microwave reactor and heat to 210 ℃ microwave solvent heat treatment for 3 hours, take it out and cool it down to room temperature naturally, centrifuge the obtained product, wash it with deionized water three times, and dry it at 80℃ for 12 hours to obtain a silver / silver phosphate composite material.

Embodiment 3

[0022] Dissolve 7.1g disodium hydrogen phosphate in 100mL deionized water to make 0.05mol / L disodium hydrogen phosphate solution A; dissolve 24.9g silver acetate solution in 300mL deionized water to make 0.5mol / L silver acetate solution B: The above two solutions A and B were mixed uniformly according to the molar ratio of 1:3 under stirring, and then centrifugally washed and dried at 80°C for 12 hours after standing still. Disperse silver phosphate and sodium fluoride in absolute ethanol according to the molar ratio of silver phosphate, sodium fluoride, and absolute ethanol at 0.005:0.001:1, then move to the reaction kettle, place in a microwave reactor and heat to 150 ℃ microwave solvent heat treatment for 3 hours, take it out and cool it down to room temperature naturally, centrifuge the obtained product, wash it with deionized water three times, and dry it at 80℃ for 12 hours to obtain a silver / silver phosphate composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com