Liquid membrane extraction method by taking hollow fiber composite membrane as liquid membrane carrier

A technology of fiber composite and composite membrane, which is applied in liquid solution solvent extraction, chemical instruments and methods, membrane technology, etc., can solve the problem of hindering mass transfer coefficient and mass transfer flux, extracting phase separation, serious stratification, extraction The problem of small phase adsorption can be achieved to increase the effect area, increase the amount of adhesion, and improve the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

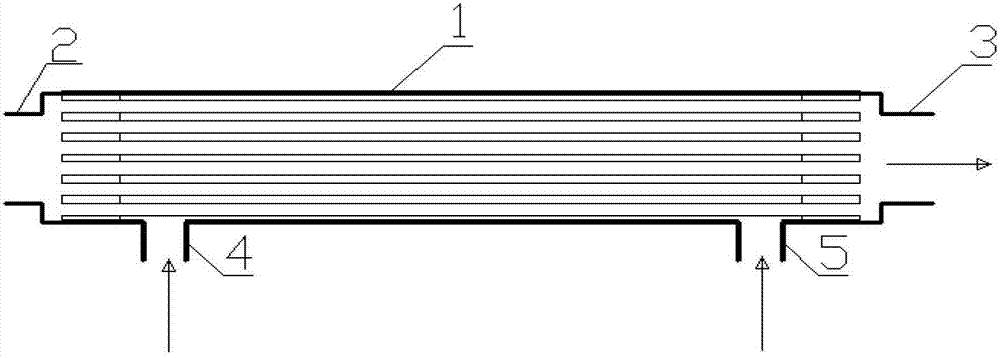

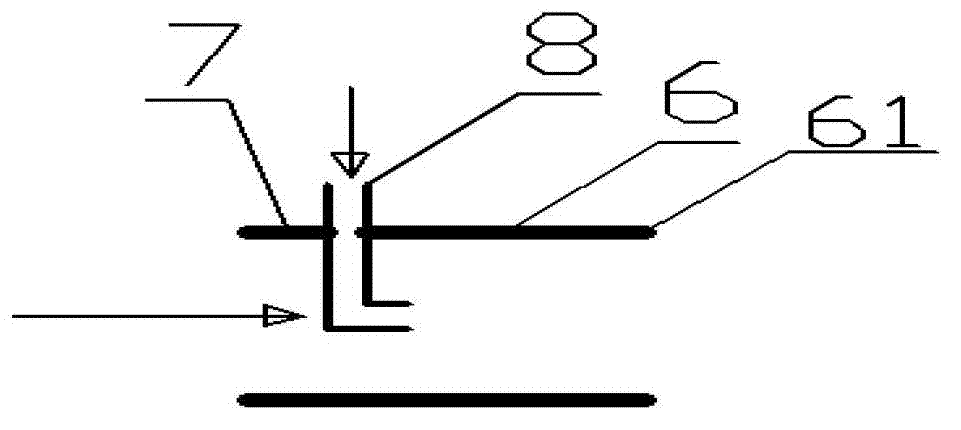

[0034] Hollow fiber composite membrane membrane module 1 and mixer 6 are self-made, such as figure 1 , figure 2 As shown, it is realized by a tubular hollow-dimensional composite membrane module 1 and a tubular mixer 6;

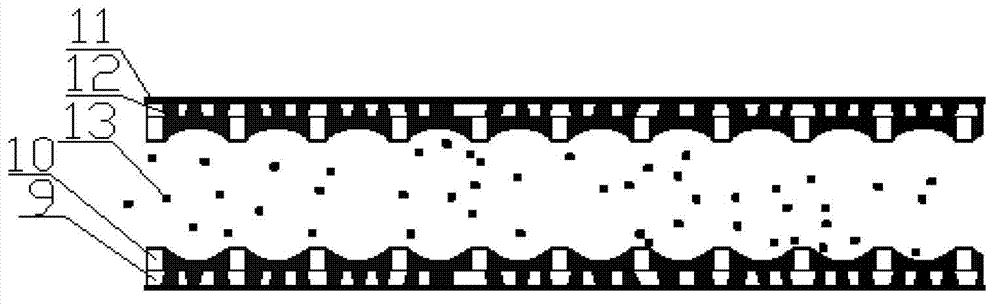

[0035]The hollow-dimensional composite membrane module 1 includes a glass tube body and a hollow fiber composite membrane packaged in the glass tube body; the hollow fiber composite membrane includes a polymer film layer and a braided tube support layer, which is uniformly coated on the surface of the braided tube support layer prepared from polymer-coated materials. The hollow channel of the hollow fiber composite membrane is the tube side, and the cavity between the outer surface of the hollow fiber composite membrane and the glass tube is the shell side; the two ends of the hollow fiber composite membrane module 1 are respectively provided with a tube side inlet 2 and a tube side outlet 3; The side wall of the glass tube is respectively provided with a ...

Embodiment 2

[0041] Adopt 4# film in table 1, change the flow velocity of the tube side in embodiment 1 to 0.7m / min, the flow rate is 2.8ml / min, the shell side flow velocity is 1.0m / min, the flow rate is 10.1ml / min, other conditions unchanged, the measured Cu at the inlet of the tube 2+ ConcentrationX f in =2200ppm, tube outlet Cu 2+ ConcentrationX f out =1927ppm, shell inlet Cu 2+ ConcentrationX s in =0ppm, Cu at shell side outlet 2+ ConcentrationX s out =268ppm, the total mass transfer coefficient K is calculated under this operating condition f =0.96×10 -5 m / s.

Embodiment 3

[0043] Hollow fiber composite membrane module 1 and mixer 6 are self-made, using 2# membrane, and the structural parameters are shown in Table 1.

[0044] Test system with Na 2 HASO 4 .7H 2 O aqueous solution is the feed liquid phase, trioctylmethylammonium chloride (Aliquat-336) / aviation kerosene=2:8 is the extraction phase, and NaCl aqueous solution is the back extraction phase. Seal the outlet 3 of the tube side of the hollow fiber composite membrane module 1, and use a peristaltic pump to inject the extract phase from the inlet 2 of the tube side of the hollow fiber composite membrane module 1, so that the extract phase flows from the hollow fiber under the pressure of the peristaltic pump. The inside of the hollow fiber composite membrane in the composite membrane membrane module 1 penetrates to the outer surface of the hollow fiber composite membrane, and then the hollow fiber composite membrane module 1 is soaked in the extraction phase for 12 hours, so that the polym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com